Silver Gallium Selenide (AgGaSe₂) is a nonlinear optical crystal with a wide transparency range of 0.73–18.3 µm, making it indispensable for mid-infrared and far-infrared optical systems. Known for its exceptional nonlinear optical coefficients (d_eff = 33 pm/V at 10.6 µm), AgGaSe₂ is commonly used in frequency conversion processes, including second-harmonic generation (SHG), optical parametric oscillation (OPO), and difference frequency generation (DFG).

With low absorption, high damage thresholds, and precise phase-matching capabilities, AgGaSe₂ is a critical component for CO₂ lasers, tunable laser sources, and infrared spectroscopy systems. Its Sellmeier equations ensure accurate refractive index calculations, allowing efficient design of nonlinear optical systems.

AgGaSe₂ crystals are versatile and widely used in high-performance nonlinear optical systems. Below are some of the key applications:

| Property | Value |

|---|---|

| Chemical Formula | AgGaSe₂ |

| Crystal Structure | Tetragonal, 42m |

| Lattice Parameters | a = 5.992 Å, c = 10.8803 Å |

| Density | 5.7 g/cm³ |

| Mohs Hardness | 3.35 |

| Melting Point | 851 °C |

| Transparency Range | 0.73 µm–18.3 µm |

| Nonlinear Coefficients | d_eff = 33 pm/V at 10.6 µm |

| Thermal Conductivity | 1.4 W/m·K |

| Thermal Expansion Coefficient | 19.8 × 10⁻⁶/°C |

| Property | Value |

|---|---|

| Nonlinear Process | SHG, DFG, SFG, and OPO |

| Refractive Indices (10.6 µm) | nₒ = 2.5917, nₑ = 2.5585 |

| Absorption Coefficient | <0.05 cm⁻¹ at 1.064 µm; <0.02 cm⁻¹ at 10.6 µm |

| Laser Damage Threshold | >10 MW/cm² (150 ns pulses at 10.6 µm) |

| Sellmeier Equations | n² = 6.6792 + 0.4598/(λ² – 0.2122) – 0.00126λ² |

| n² = 6.8507 + 0.4297/(λ² – 0.1584) – 0.00125λ² |

| Specification | Value |

|---|---|

| Dimensions | 5 × 5 × 1 mm (standard) |

| Surface Flatness | Lambda/6 @ 632.8 nm |

| Parallelism | < 30 arc seconds |

| Perpendicularity | < 10 arc minutes |

| Surface Quality | 60-40 Scratch-Dig |

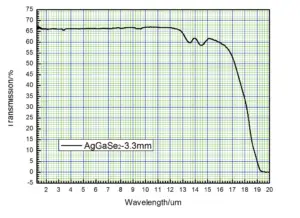

The spectrum transmission range of AgGaSe₂ is characterized by high transparency between 0.73 and 18.3 µm. The crystal shows minimal losses across this range, making it suitable for mid-IR and far-IR applications.

Key Characteristics:

(Note: Graphical data can be generated or requested from POC’s technical team.)

| Product Code | Dimensions (mm) | Coating | Price (USD) |

|---|---|---|---|

| AGSE-01 | 2 × 2 × 1 | BBAR @ 1.7–2.7 µm | Request Quote |

| AGSE-02 | 5 × 5 × 1 | BBAR @ 5–18 µm | Request Quote |

| AGSE-03 | 10 × 10 × 2 | BBAR @ 1.7–18 µm | Request Quote |

| Custom-AGSE | Customizable | Customizable | Request Quote |