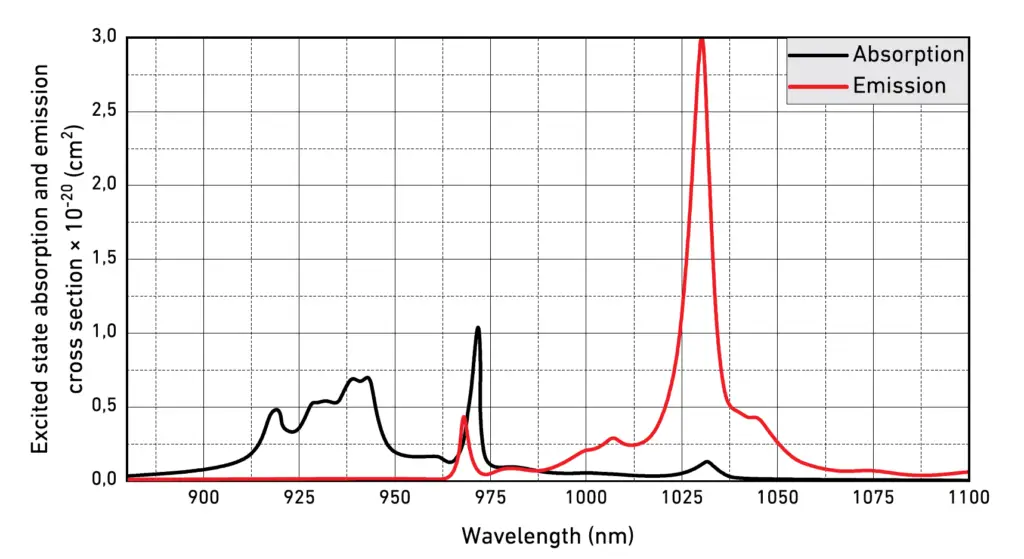

Ytterbium-doped Yttrium Aluminum Garnet (Yb:YAG Crystal) is a highly efficient and versatile laser crystal designed for diode-pumped solid-state laser systems. Yb:YAG’s simple electronic structure excludes excited-state absorption, resulting in minimal detrimental quenching processes. Compared to the widely used Nd:YAG, Yb:YAG Crystal exhibits a broader absorption band near 940 nm, allowing better thermal management and more efficient pump utilization.

Yb:YAG Crystal is widely recognized for its high thermal conductivity and mechanical robustness, making it ideal for high-power and thin-disk laser configurations. Its low quantum defect (~9%) significantly reduces heat generation, extending the laser system’s lifetime and ensuring stable operation. The crystal’s emission at 1030 nm makes it a strong candidate for replacing Nd:YAG in applications requiring better thermal efficiency.

Yb:YAG crystals are employed across various high-tech industries due to their excellent optical and mechanical properties. Some key applications include:

Example: Yb:YAG thin-disk lasers enable efficient machining with minimal thermal distortion, making them ideal for intricate manufacturing processes.

| Property | Specification |

|---|---|

| Laser Wavelength | 1030 nm |

| Stimulated Emission Cross Section | 2.0 × 10⁻²⁰ cm² |

| Fluorescence Lifetime | 950 µs |

| Linewidth | 9 nm |

| Loss Coefficient | 0.003 cm⁻¹ |

| Absorption Bandwidth | 8 nm @ 940 nm |

| Thermal Optical Coefficient | 9 × 10⁻⁶/K |

| Property | Specification |

|---|---|

| Laser Wavelength | 1030 nm |

| Stimulated Emission Cross Section | 2.0 × 10⁻²⁰ cm² |

| Fluorescence Lifetime | 950 µs |

| Linewidth | 9 nm |

| Loss Coefficient | 0.003 cm⁻¹ |

| Absorption Bandwidth | 8 nm @ 940 nm |

| Thermal Optical Coefficient | 9 × 10⁻⁶/K |

| Specification | Value |

|---|---|

| Dopant Concentration | 0.5–20 atm% |

| Surface Quality | 10/5 to MIL-PRF-13830B |

| Wavefront Distortion | < λ/8 @ 633 nm |

| Parallelism | < 20 arc seconds |

| Perpendicularity | < 15 arc minutes |

| Surface Flatness | < λ/10 @ 633 nm |

| Chamfer | 0.2 mm x 45° |

| Length Tolerance | ±0.5 mm |

| Diameter Tolerance | ±0.1 mm |

Yb:YAG typically demonstrates high transmittance in the range of 900–1100 nm, peaking near 1030 nm.

| Coating Type | Specification |

|---|---|

| AR Coating | R < 0.2% @ 1030 nm |

| HR Coating | R > 99.8% @ 1030 nm |

| Other Coatings | Available for 940 nm or upon request |

Adhesion Test: Compliant with MIL-C-675C military standards, an adhesion test involved applying a tape that meets LT-90 specifications onto the lens film layer. The tape was affixed fully and then removed vertically. This procedure was performed three times, resulting in no blistering or peeling.

Temperature Test: In line with MIL-C-675C specifications, test pieces were subjected to temperatures of -62±1℃ and 71±1℃. After maintaining them at room temperature (16℃~32℃) for two hours, the adhesion test was repeated, confirming no film detachment.

Abrasion Resistance Test: Conforming to MIL-C-675C and CCC-C-440 standards, the abrasion resistance test involved a gauze tester applying a minimum force of 1.0 lbs (0.45 kg) to the film. This was repeated 25 times with gauze widths of 1/4 inch (6.4mm) and 3/8 inch (9.5mm), ensuring no damage occurred to the film surface.

Humidity Test: Under MIL-C-675C criteria, the test piece was placed in a controlled temperature and humidity chamber set to 49 ±2℃ and 95%~100% humidity for 24 hours. The film remained intact, with no peeling, scratches, or other defects.

Solvent and Cleaning Testing: Following MIL-C-675C specifications, test pieces were exposed to room temperature conditions (16℃~32℃) and tested with acetone and alcohol for at least 10 minutes each. After air drying and subsequent cleaning with a cotton cloth soaked in alcohol, the film surface showed no signs of peeling or scratches.

Salt Spray Test: After 100 hours in a 35°C environment with a 5% saltwater concentration, the film showed no signs of damage.

| Dimension | Length | Dopant (%) | End Faces | Coating | Price (USD) |

|---|---|---|---|---|---|

| 10 x 10 mm | 5 mm | 5% | Right-angle cut | AR @ 1030 nm | $540 |

| 2 x 2 mm | 10 mm | 10% | Right-angle cut | AR/HR Coated | $500 |

| 5 x 5 mm | 15 mm | 1% | Brewster-angle | AR @ 940/1030 nm | $600 |

| Customization Available | Yes | Upon Request | Upon Request | Upon Request | Upon Request |