Ytterbium-doped Potassium Gadolinium Tungstate (Yb:KGW) is a monoclinic crystal known for its broad emission bandwidth, making it suitable for ultrafast laser applications. It features high thermal conductivity, enabling efficient heat dissipation under intense laser pumping conditions. The unique structural properties of Yb:KGW allow operation with high doping concentrations, minimizing quantum defects. These characteristics ensure low lasing thresholds, high efficiency, and superior performance for femtosecond lasers, CW lasers, and regenerative amplifiers.

Yb:KGW crystals are widely used in:

| Property | Value |

|---|---|

| Crystal Structure | Monoclinic |

| Point Group | C2/c |

| Lattice Parameters (Å) | a = 8.09, b = 10.43, c = 7.588, β = 94.4° |

| Density | 7.27 g/cm³ |

| Melting Point | 1075 °C |

| Mohs Hardness | 5 |

| Thermal Conductivity (W/m·K) | K_100 = 3.4, K_a = 2.6 |

| Thermal Expansion Coefficients | a = 4 × 10^-6 K^-1, b = 8.5 × 10^-6 K^-1 |

| Parameter | Specification |

|---|---|

| Orientation | [010] |

| Standard Dopant Level | 5 at.% |

| Maximum Length | 50 mm |

| Dimensional Tolerances | Diameter: ±0.1 mm, Length: ±0.5 mm |

| Surface Quality (Scratch/Dig) | 20/10 |

| Surface Flatness | λ/6 @ 633 nm |

| Parallelism | 20 arc sec |

| Perpendicularity | ≤15 arc min |

| Specification | Value |

|---|---|

| Dimension Tolerance | ±0.1 mm (standard); ±0.005 mm (high precision) |

| Clear Aperture | Central 95% of the diameter |

| Surface Quality | 20-10 Scratch-Dig |

| Surface Flatness | λ/8 at 633 nm |

| Parallelism | <10 arc seconds |

| Perpendicularity | <5 arc minutes |

| Chamfer | 0.1 mm at 45° |

| Damage Threshold | >15 J/cm² (10 ns, 10 Hz at 1064 nm) |

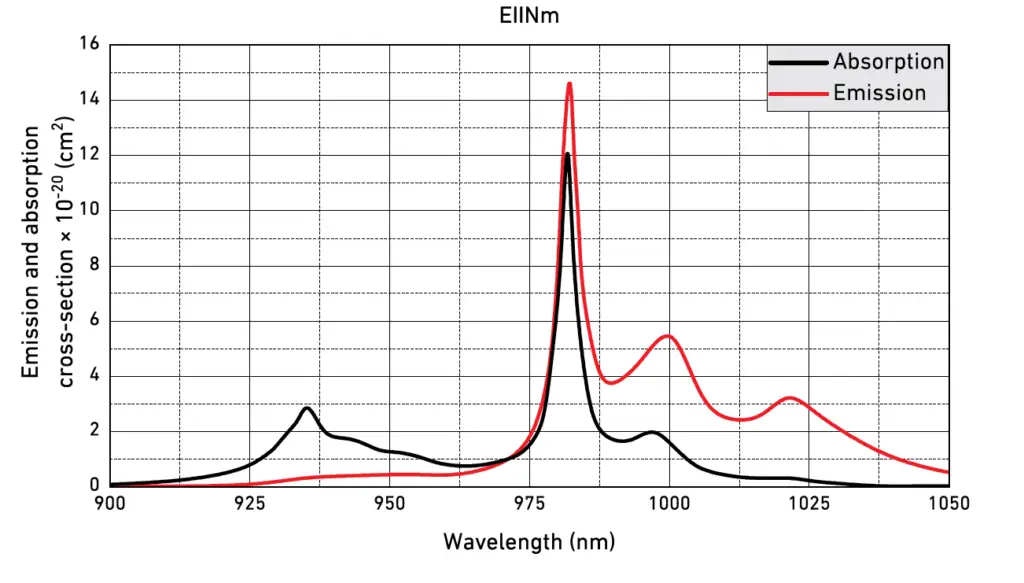

The absorption and emission spectra highlight the broad bandwidth at 981 nm and efficient emission around 1030 nm, suitable for femtosecond and thin-disk lasers.

Adhesion Test: Compliant with MIL-C-675C military standards, an adhesion test involved applying a tape that meets LT-90 specifications onto the lens film layer. The tape was affixed fully and then removed vertically. This procedure was performed three times, resulting in no blistering or peeling.

Temperature Test: In line with MIL-C-675C specifications, test pieces were subjected to temperatures of -62±1℃ and 71±1℃. After maintaining them at room temperature (16℃~32℃) for two hours, the adhesion test was repeated, confirming no film detachment.

Abrasion Resistance Test: Conforming to MIL-C-675C and CCC-C-440 standards, the abrasion resistance test involved a gauze tester applying a minimum force of 1.0 lbs (0.45 kg) to the film. This was repeated 25 times with gauze widths of 1/4 inch (6.4mm) and 3/8 inch (9.5mm), ensuring no damage occurred to the film surface.

Humidity Test: Under MIL-C-675C criteria, the test piece was placed in a controlled temperature and humidity chamber set to 49 ±2℃ and 95%~100% humidity for 24 hours. The film remained intact, with no peeling, scratches, or other defects.

Solvent and Cleaning Testing: Following MIL-C-675C specifications, test pieces were exposed to room temperature conditions (16℃~32℃) and tested with acetone and alcohol for at least 10 minutes each. After air drying and subsequent cleaning with a cotton cloth soaked in alcohol, the film surface showed no signs of peeling or scratches.

Salt Spray Test: After 100 hours in a 35°C environment with a 5% saltwater concentration, the film showed no signs of damage.

| Face Dimensions | Length | End Faces | Doping | Coatings | Price (USD) |

|---|---|---|---|---|---|

| 3 × 3 mm | 10 mm | Brewster-angle cut | 1% | Uncoated | $590 |

| 5 × 5 mm | 5 mm | Right-angle cut | 2% | AR 980/1030 nm | $640 |

| 3 × 3 mm | 2 mm | Brewster-angle cut | 3% | Uncoated | $590 |

| 5 × 5 mm | 5 mm | Right-angle cut | 5% | AR 980/1030 nm | $640 |

| Custom Size | Custom | Any | Custom | Custom | Request |