The Er:Cr:YSGG (Erbium and Chromium-doped Yttrium Scandium Gallium Garnet) crystal is a high-performance laser crystal known for generating 2800 nm light in a critical water absorption band. It boasts high conversion efficiency, stable chemical durability, and a long fluorescence lifetime, making it one of the most promising laser media. The crystal operates efficiently under CW or pulsed laser conditions, making it versatile for dental lasers, environmental sensing, optical communication, and military applications. Due to its intrinsic structural properties, Er:Cr:YSGG Crystal has excellent tenability, increasing its appeal across diverse scientific and industrial domains.

Er:Cr:YSGG is extensively used in several advanced applications due to its high energy efficiency and versatility:

| Property | Specification |

|---|---|

| Crystal Structure | Cubic, Garnet |

| Chemical Formula | Y3Sc2-xGaxGa3O12 |

| Lattice Parameter | 12.42 Å |

| Dopant Concentration | Cr: 0.5 × 10^20 (atoms/cm³), Er: 4 × 10^21 (atoms/cm³) |

| Growth Method | Czochralski |

| Density | 5.67 g/cm³ |

| Refractive Index | 1.92 at 1000 nm |

| Thermal Expansion Coefficient | 8.1 × 10^-6 K⁻¹ |

| Thermal Conductivity | 8 W/m/K |

| Mohs Hardness | 8 Mohs |

| Thermo-optical Factor | 12.3 × 10^-6 K⁻¹ |

| Emission Cross-section | 5.2 × 10^-20 cm² |

| Fluorescence Lifetime | 1400 µs |

| Parameter | Value |

|---|---|

| Laser Wavelength | 2800 nm |

| Peak Absorption Cross-section | 5.2 × 10^-20 cm² |

| Fluorescence Lifetime | 1400 µs |

| Thermo-optical Coefficient | 12.3 × 10^-6 K⁻¹ |

| Emission Linewidth | Broad and tunable |

| Pump Source | Diode-pumped via Cr or Er bands |

| Mode of Operation | CW, free-running, Q-switched |

| Specification | Value |

|---|---|

| Rod Size | Diameter: 3–6 mm, Length: 50–120 mm |

| Surface Quality | 10/5 per MIL-PRF-13830B |

| Flatness | < λ/8 @ 633 nm |

| Parallelism | <20 arc sec |

| Perpendicularity | <15 arc min |

| Chamfer | <0.2 mm × 45° |

| Coating Options | AR-coated or HR-coated upon request |

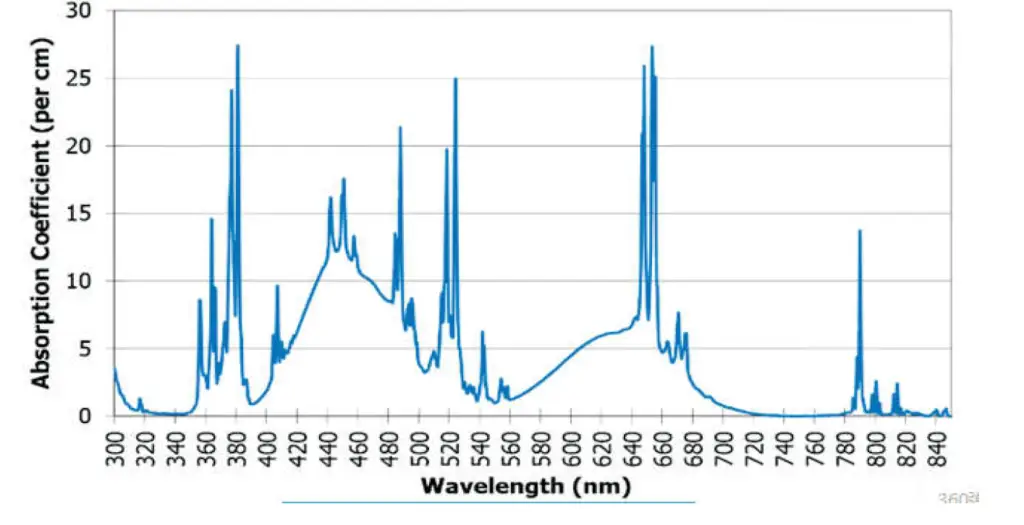

The absorption spectrum for Er:Cr:YSGG demonstrates strong peaks around 2800 nm, aligning well with water molecule absorption. Its broad tunability and strong fluorescence peaks enhance its utility in high-precision applications

| Dimensions | Length | End Faces | Doping | Coating | Price (USD) |

|---|---|---|---|---|---|

| 3 × 3 mm | 10 mm | Brewster-angle cut | Cr, Er doped | Uncoated | $450 |

| 4 × 4 mm | 20 mm | Right-angle cut | Cr, Er doped | AR-coated @2800 nm | $500 |

| 5 × 5 mm | 30 mm | Brewster-angle cut | Cr, Er doped | HR-coated | $600 |

| Customization | As needed | As needed | As requested | As requested | Request Quote |