Praseodymium-doped Lithium Yttrium Fluoride (Pr:YLF) crystal is a robust and versatile material for producing visible solid-state lasers. With its high absorption cross-section in the blue spectral region and overlapping emission lines of InGaN diodes, Pr:YLF is widely used for both research and industrial applications. The material features excellent thermal conductivity and a tetragonal structure, providing stability under high-power operations. The unique energy level transitions of Pr³⁺ allow generation of red, orange, green, and blue lasers, making it ideal for multicolor and high-intensity laser systems.

Pr:YLF crystals are essential for diode-pumped solid-state lasers and have a broad spectrum of applications, such as:

Pr:YLF crystals are particularly advantageous for lasing in the visible spectrum, with transitions at:

These unique properties make Pr:YLF Crystal indispensable for visible laser generation directly from solid-state systems.

| Property | Value |

|---|---|

| Chemical Formula | Pr³⁺:LiYF₄ |

| Crystal Structure | Tetragonal |

| Refractive Index (at 1064 nm) | n_o = 1.448, n_e = 1.470 |

| Density | 3.95 g/cm³ |

| Mohs Hardness | 5 |

| Thermal Conductivity | 6 W/m·K |

| Thermal Expansion Coefficient | -1.6 x 10^-6 /K |

| Typical Doping Level | <1.3% |

| Parameter | Value |

|---|---|

| Absorption Peak Wavelength | 444 nm |

| Absorption Cross-section | 8 x 10^-19 cm² |

| Absorption Bandwidth | ~5 nm |

| Emission Wavelengths | 523 nm, 607 nm, 640 nm |

| Emission Cross-section | 20 x 10^-19 cm² |

| Fluorescence Lifetime | 50 µs |

| Specification | Value |

|---|---|

| Orientation | c-cut |

| Clear Aperture | >90% |

| Face Dimensions Tolerance | +0.0/-0.1 mm |

| Length Tolerance | ±0.1 mm |

| Surface Quality (Scratch/Dig) | 20-10 |

| Surface Flatness | λ/8 @ 633 nm |

| Parallelism Error | <20 arcsec |

| Perpendicularity Error | <10 arcmin |

| Chamfer | <0.1 mm at 45° |

| Laser Damage Threshold | >5 J/cm² @ 532 nm, 10 ns |

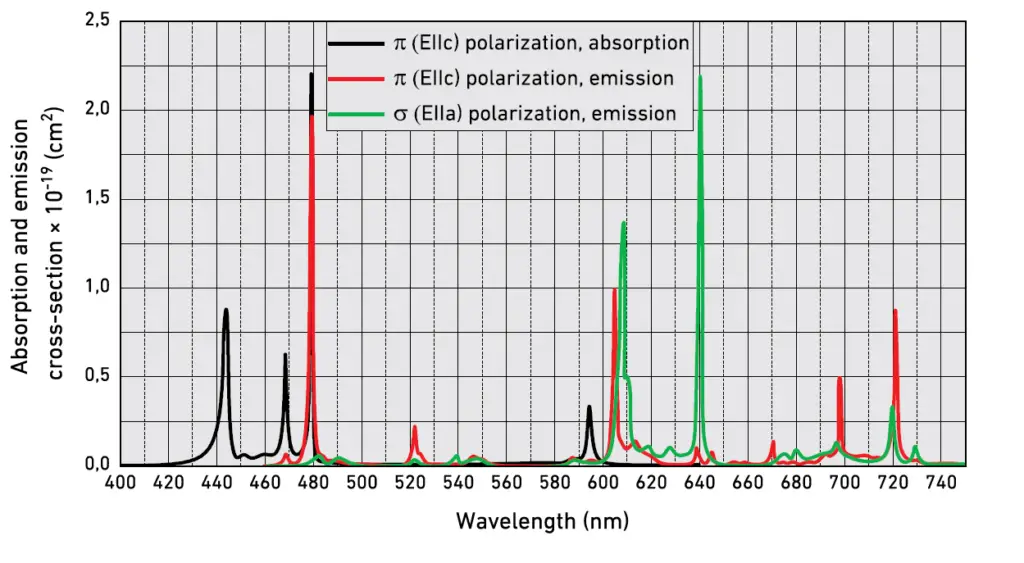

The transmission spectrum is available, showing high absorption and emission peaks at visible wavelengths, particularly in the red, green, and blue regions. This curve confirms the crystal’s efficiency for multicolor laser operations.

| Face Dimensions (mm) | Length (mm) | End Faces | Doping (%) | Coatings | Price (USD) |

|---|---|---|---|---|---|

| 2 x 2 | 6 | Right-angle cut | 0.5 | AR @ 440-725 nm | 480 |

| 3 x 3 | 6 | Right-angle cut | 0.5 | AR @ 440-725 nm | 540 |

| 5 x 5 | 6 | Right-angle cut | 0.5 | AR @ 440-725 nm | 640 |

| Custom Size | Upon Request | Brewster/Right Cut | Upon Request | Custom coatings available | Upon Request |