Holmium-doped Yttrium Lithium Fluoride (Ho:YLF) is a highly efficient laser crystal material used in various optical applications, including industrial processing, defense, and environmental monitoring. With its naturally birefringent properties, Ho:YLF minimizes thermal lensing effects and ensures stable output. The crystal exhibits a long upper laser level lifetime, enhancing its suitability for Q-switched laser operations. The optimized doping levels, high emission cross-section, and strong absorption make it an ideal choice for generating emission wavelengths around 2060 nm, particularly for pollutant detection and remote sensing. Ho:YLF Crystal also supports customizations such as doping concentrations and coatings to meet user-specific requirements.

Ho:YLF crystals are versatile and cater to a broad range of industries:

| Property | Value |

|---|---|

| Crystal Structure | Tetragonal |

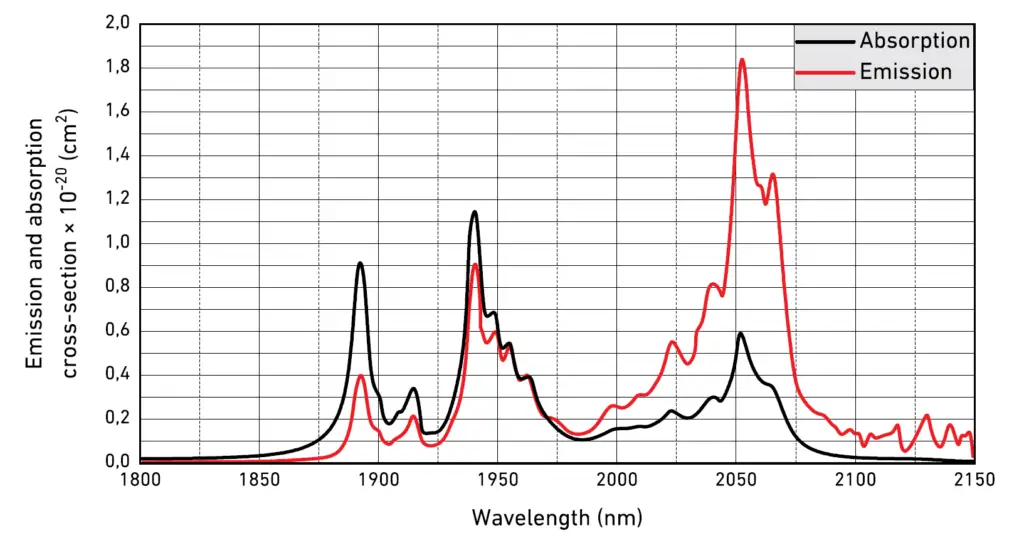

| Absorption Peak Wavelength | 1940 nm |

| Emission Wavelength | 2060 nm |

| Absorption Cross-Section | 1.2 x 10^-22 cm^2 |

| Emission Cross-Section | 1.8 x 10^-22 cm^2 |

| Refractive Index (1064 nm) | n_o = 1.448, n_e = 1.470 |

| Density | 3.95 g/cm^3 |

| Mohs Hardness | 5 |

| Thermal Conductivity | 6 W/m·K |

| Thermal Expansion Coefficient | 10.1 x 10^-6 K^-1 ( |

| Typical Doping Level | 0.5% |

| Optical Property | Value |

|---|---|

| Absorption Bandwidth | ~18 nm |

| Lifetime of ^5I_7 Energy Level | 10 ms |

| LIDT | >10 J/cm^2 @ 2060 nm, 10 ns |

| Coating Options | AR coatings at 1900-2100 nm |

| Parameter | Specification |

|---|---|

| Orientation | z-cut |

| Clear Aperture | >90% |

| Face Dimension Tolerance | +0.0/-0.1 mm |

| Length Tolerance | ±0.1 mm |

| Parallelism Error | <20 arc seconds |

| Perpendicularity Error | <10 arc minutes |

| Surface Quality | 20-10 S-D |

| Surface Flatness | <λ/10 @ 632.8 nm |

The materials shows high absorption and emission characteristics at 2060 nm, with minimal losses and high efficiency in the Q-switched regime.

| Face Dimensions (mm) | Length (mm) | End Faces | Doping | Coatings | Price (USD) |

|---|---|---|---|---|---|

| 5 x 5 | 2 | Brewster-angle cut | 1% | Uncoated | $620 |

| 5 x 5 | 2 | Right-angle cut | 1% | AR@1900-2100 nm | $750 |

| 8 x 8 | 2 | Brewster-angle cut | 1% | Uncoated | $620 |

| 8 x 8 | 2 | Right-angle cut | 1% | AR@1900-2100 nm | $750 |

| Customization Available | Customizable | Upon request | Custom | Custom coatings | Contact Us |