Tm:Ho:KYW (Thulium, Holmium co-doped Potassium Yttrium Tungstate) crystals are highly efficient laser gain mediums operating in the mid-infrared range (~2 µm). These crystals are characterized by broad polarized absorption and emission bands, making them suitable for applications requiring precise wavelength tunability. The co-doping of Tm³⁺ and Ho³⁺ ions facilitates efficient energy transfer, enabling enhanced laser performance. The monoclinic crystal structure ensures high thermal stability, while the superior spectroscopic and mechanical properties make it a preferred choice for advanced laser systems.

Tm:Ho:KYW crystals have become critical for remote sensing, medical treatments, and industrial applications due to their robustness and consistent output at eye-safe wavelengths.

| Parameter | Value |

|---|---|

| Chemical Formula | Tm, Ho:KYW (K(Y,W)O₄) |

| Crystal Structure | Monoclinic |

| Density | 3.95 g/cm³ |

| Mohs Hardness | 6.5 |

| Thermal Conductivity | 3.3 W/m·K |

| Thermal Expansion Coefficient | 10.5 × 10⁻⁶ /°C (a-axis) |

| Typical Doping Level | 5 at.% (Tm³⁺), 1 at.% (Ho³⁺) |

| Lattice Constants | a = 7.2 Å, b = 10.3 Å, c = 7.5 Å |

| Parameter | Value |

|---|---|

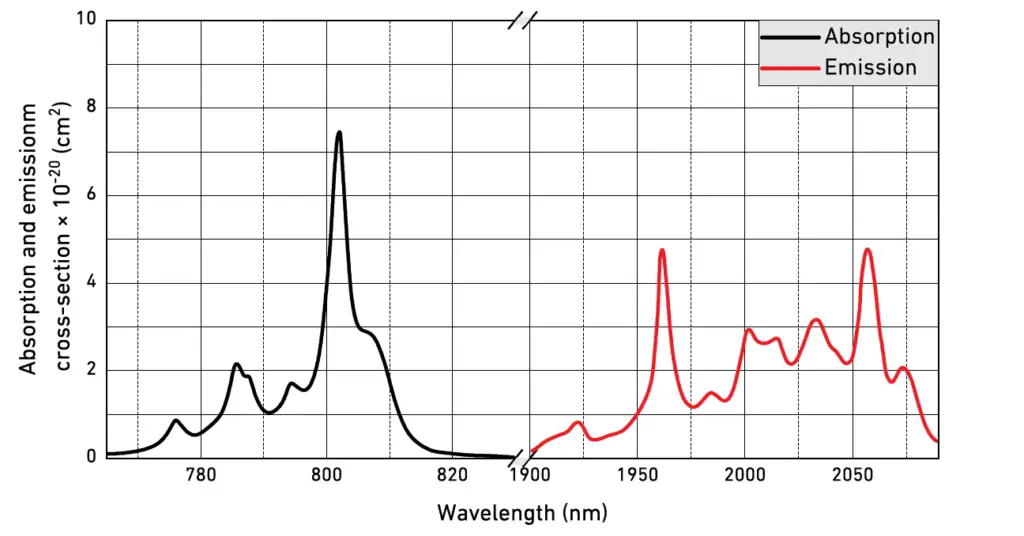

| Laser Wavelength | 2060 nm |

| Absorption Peak Wavelength | 802 nm |

| Absorption Cross Section | 7.6 × 10⁻²⁰ cm² |

| Emission Cross Section | 4.7 × 10⁻²⁰ cm² |

| Absorption Bandwidth at Peak | ~4 nm |

| Lifetime of T₁ Energy Level | 1.8 ms |

| Refractive Index (@1040 nm) | nₑ = 2.05, nₒ = 1.97 |

| Specification | Value |

|---|---|

| Orientation | Nₐ-cut |

| Clear Aperture | >90% |

| Face Dimensions Tolerance | ±0.1 mm |

| Length Tolerance | ±0.1 mm |

| Parallelism Error | <20 arcsec |

| Perpendicularity Error | <10 arcmin |

| Surface Flatness | λ/10 @ 632.8 nm |

| Surface Quality | 20-10 S-D |

| Protective Chamfers | <0.1 mm at 45° |

Refer to the transmission chart for absorption and emission properties across key wavelengths, highlighting peak values at 802 nm (absorption) and 2060 nm (emission). If additional data is required, please contact POC for technical reports.

| Face Dimensions | Length | End Faces | Doping | Coatings | Price (USD) |

|---|---|---|---|---|---|

| 5 x 5 mm | 2 mm | Brewster-angle cut | 1% | Uncoated | 620 |

| 5 x 5 mm | 2 mm | Right-angle cut | 1% | AR@802 nm + AR@2100 nm | 750 |

| 8 x 8 mm | 2 mm | Brewster-angle cut | 1% | Uncoated | 620 |

| 8 x 8 mm | 2 mm | Right-angle cut | 1% | AR@802 nm + AR@2100 nm | 750 |

| Customization | Custom | Custom options | Custom | Available upon request | Request Quote |