Er:KYW (Erbium-doped Potassium Yttrium Tungstate) crystals are a promising active laser medium for “eye-safe” wavelength emissions, particularly in the 1570-1630 nm spectral range. These crystals are tailored for diode-pumped solid-state lasers, benefiting from their broad absorption and emission bands. Their high efficiency in energy transfer, coupled with excellent thermo-mechanical properties, makes them suitable for high-power and pulsed laser systems. Er:KYW crystals exhibit a low quantum defect, allowing superior slope efficiencies when pumped by InGaAs/InP diode lasers. The broad emission spectrum also supports the generation of mode-locked laser pulses.

Er:KYW crystals find applications across a wide range of laser systems, including:

| Property | Value |

|---|---|

| Chemical Formula | Er:KY(WO₄)₂ |

| Absorption Peak Wavelength | 1534 nm |

| Emission Wavelength | 1609 nm |

| Absorption Bandwidth (at peak) | 3 nm |

| Emission Cross-Section | 0.4 × 10^-20 cm² |

| Lifetime of Er³⁺ Upper Laser Level | 3.1 ms |

| Refractive Index | n_p = 2.05, n_m = 2.01, n_g = 1.97 |

| Crystal Structure | Monoclinic |

| Density | 6.5 g/cm³ |

| Mohs Hardness | 5 |

| Thermal Conductivity | 3.5 W/m·K |

| Typical Doping Level | <20 at.% |

| Optical Property | Value |

|---|---|

| Absorption Coefficient at Peak | 2.4 × 10^-20 cm² |

| Absorption Wavelength Range | 1520-1540 nm |

| Emission Cross-Section | 0.4 × 10^-20 cm² |

| Emission Bandwidth | 3 nm |

| Laser Wavelength | 1570-1630 nm |

| Efficiency | >80% (High slope efficiency) |

| Transparency Range | 400 nm to 5 μm |

| Specification | Value |

|---|---|

| Orientation | N_p-cut (standard), other cuts available |

| Clear Aperture | >90% |

| Face Dimensions Tolerance | +0/-0.1 mm |

| Length Tolerance | ±0.1 mm |

| Parallelism Error | <20 arcsec |

| Perpendicularity Error | <10 arcmin |

| Surface Flatness | <λ/10 @ 632.8 nm |

| Surface Quality | 20-10 S-D |

| Laser Damage Threshold | >10 J/cm² @1530 nm, 10 ns |

| Mount | Unmounted |

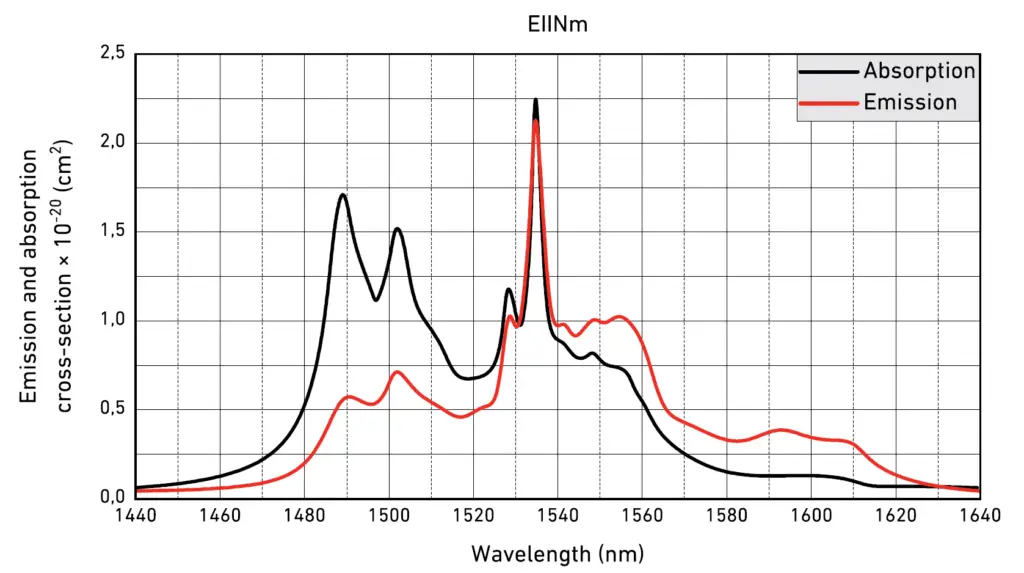

The absorption and emission spectra indicate strong absorption at 1534 nm and significant emission near 1609 nm. This aligns well with the emission wavelengths of InGaAs/InP diode lasers, making Er:KYW ideal for these systems.

| Face Dimensions (mm) | Length (mm) | Coating | Price (USD) |

|---|---|---|---|

| 3 × 3 | 5 | AR/AR@1530-1600 nm | Request |

| 3 × 3 | 10 | AR/AR@1530-1600 nm | Request |

| Customization | Available | Upon Request | Request |