BaF₂ (Barium Fluoride) is a high-performance optical material belonging to the cubic crystal system. Known for its excellent optical transmittance across a wide spectral range from UV to IR wavelengths, BaF₂ crystals are widely utilized in optical windows, lenses, and prisms. These crystals exhibit excellent radiation resistance and scintillation properties, making them highly desirable in applications like high-energy physics, nuclear medicine, and spectroscopy.

BaF₂ also demonstrates remarkable thermal and mechanical stability, which enhances its performance in demanding environments. Its high UV transmittance is particularly suited for ultraviolet spectrometry and related fields. Additionally, BaF₂ is available in both monocrystalline and polycrystalline forms, ensuring versatility for diverse applications.

BaF₂ crystals are utilized in a variety of fields due to their outstanding optical and scintillation properties:

|

Properties |

Details |

|---|---|

|

Material Grade |

VIR, UV, Scintillating Crystals |

|

Crystal Structure |

Cubic System |

|

Cleavage Plane |

(111) |

|

Density |

4.89 g/cm³ |

|

Melting Point |

1280 °C |

|

Thermal Conductivity |

11.72 W/m·K at 286 K |

|

Thermal Expansion |

18.1 × 10⁻⁶ /°C at 273 K |

|

Knoop Hardness |

82 kg/mm² |

|

Solubility |

0.0017 g @ 23 °C |

|

Young’s Modulus (E) |

53.07 GPa |

|

Shear Modulus (G) |

25.4 GPa |

|

Bulk Modulus (K) |

56.4 GPa |

|

Apparent Elastic Limit |

26.9 MPa (3900 psi) |

|

Poisson Ratio |

0.343 |

|

Properties |

Details |

|---|---|

|

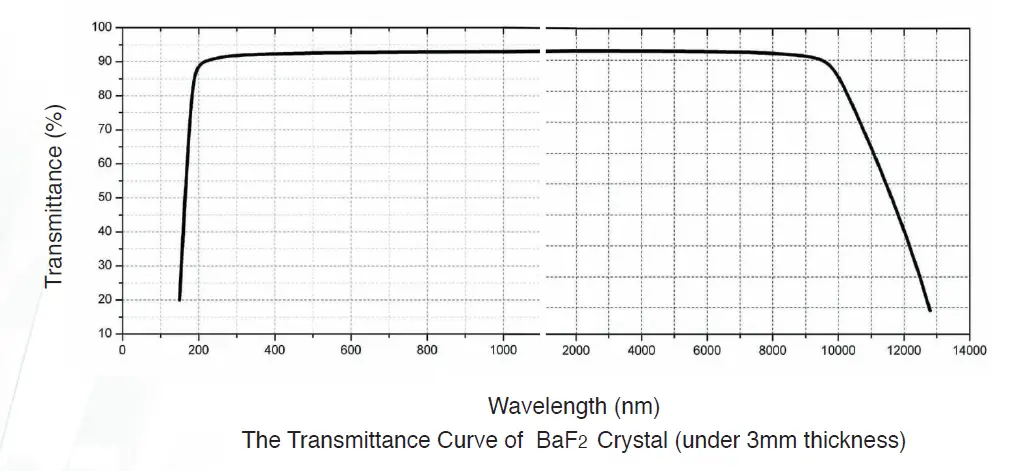

Transmittance Range |

0.15 µm – 14 µm |

|

Transmittance |

>94% at 350 nm – 10.8 µm |

|

Refractive Index |

1.4624 at 2.58 µm / 1.3936 at 10.35 µm |

|

Reflection Loss |

6.8% at 2.58 µm / 5.3% at 10.35 µm |

|

Radiation Length |

20.6 mm |

|

Residual Radiation Peak |

47 nm |

|

Decay Constant |

620 ns (slow), 0.6 ns (fast) |

|

Emission Peak |

310 nm (slow), 220 nm (fast) |

|

Light Output |

20% (slow), 4% (fast) |

|

Absorption Coefficient |

3.2 × 10⁻⁴ @6 µm |

|

dn/dT |

-15.2 × 10⁻⁶ |

|

Specification |

Details |

|---|---|

|

Maximum Diameter |

Up to 300 mm |

|

Clear Aperture |

>85% |

|

Surface Quality |

20/10 |

|

Surface Flatness |

λ/4 @ 633 nm |

|

Crystal Orientation |

<111>, <100>, or custom |

|

Mount |

Upon Customer’s Specification |

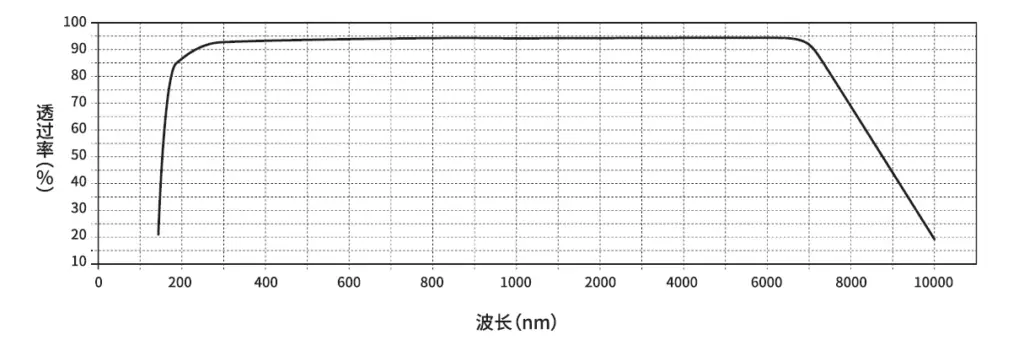

Transparency Range: BaF₂ exhibits high transmittance from UV to IR, with >94% transmittance in the range of 150 nm to 10.8 µm.

| Face Dimensions (mm) | Length (mm) | Coating | SKU | Price (USD) |

|---|---|---|---|---|

| 15 x 15 | 15 | Uncoated | 7273 | 440 |

| 30 x 30 | 30 | AR (450-800 nm) | 7276 | 600 |

| 50 x 50 | 50 | AR (450-800 nm) | 31051 | 900 |

| Customization Available | On Request | As per demand | N/A | Varies |