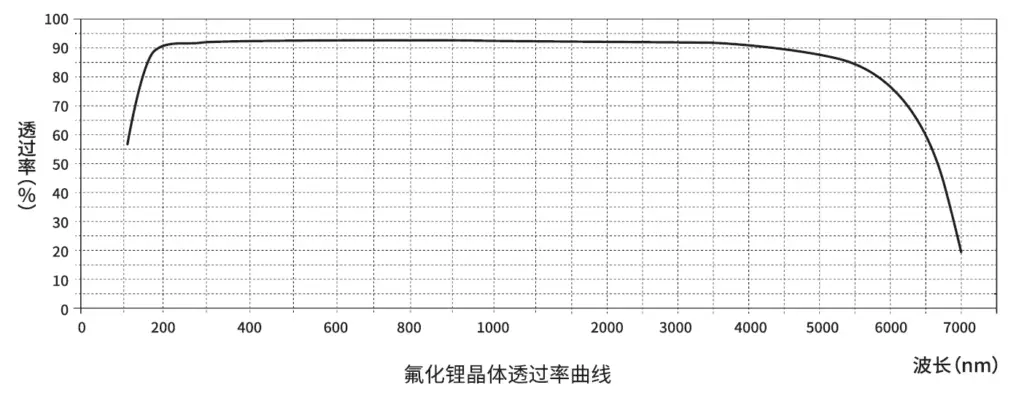

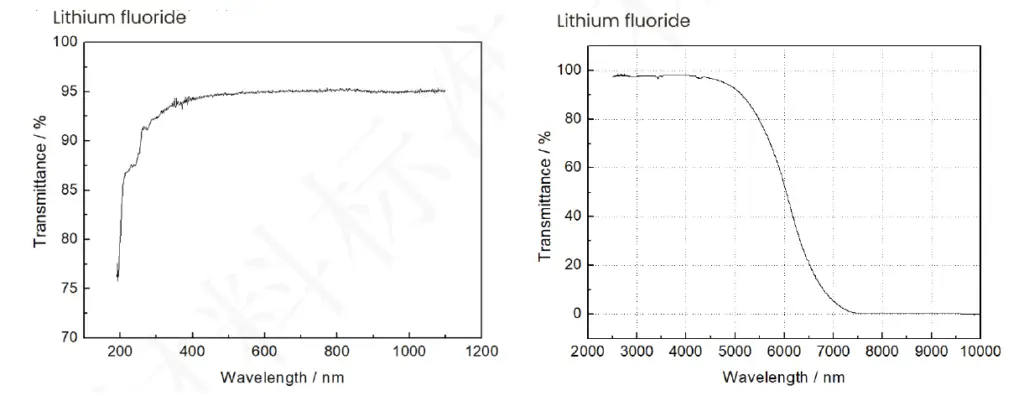

Lithium Fluoride (LiF) crystal is known for its remarkable optical properties, including high transmittance in the ultraviolet (UV), visible, and near-infrared regions, spanning wavelengths from 105 nm to 6 μm. It possesses the lowest refractive index among commonly used infrared materials, making it indispensable for applications that demand minimal optical distortion. LiF crystals are highly resistant to radiation damage, which enhances their reliability in extreme environments such as aerospace and thermal imaging applications. They also feature excellent thermal and chemical stability, contributing to their usability in high-energy optics. Additionally, LiF is employed as optical elements in X-ray diffraction devices due to its unique crystal lattice properties.

LiF crystals find extensive applications across various fields:

These properties make LiF crystals a versatile material for cutting-edge technological advancements.

| Property | Value |

|---|---|

| Density (g/cm³) | 2.64 |

| Melting Point (°C) | 845 |

| Thermal Conductivity (W·m⁻¹·K⁻¹) | 11.3 @ 314 K |

| Thermal Expansion (°C⁻¹) | 37 × 10⁻⁶ |

| Hardness (Mohs) | 4 |

| Dielectric Constant | 9.0 @ 100 Hz |

| Elastic Coefficient | C₁₁=112; C₁₂=45.6; C₄₄=63.2 |

| Crystal Structure | Cubic System |

| Cleavage Plane | (100) |

| Solubility (g @ 18°C) | 0.27 |

| Refractive Index | 1.3733 @ 2.5 μm |

| Property | Value |

|---|---|

| Transmittance Range (μm) | 0.105–6 |

| Transmittance (%) | >90% @ 0.3–4.5 μm |

| Refractive Index | nₒ=1.3733 @ 2.5 μm; nₑ=1.6240 @ 121 nm |

| Reflection Loss (%) | 4.4% @ 4 μm (both surfaces) |

| Parameter | Specification |

|---|---|

| Dimension Tolerance | ±0.1 mm |

| Surface Flatness | λ/4 @ 633 nm |

| Parallelism | <3 arcmin |

| Surface Quality | 20/10 (Scratch/Dig) |

| Clear Aperture | >90% |

| Chamfer | <0.25 × 45° |

The transmission curve demonstrates LiF’s superior transmittance across wavelengths ranging from 105 nm to 6 μm. This property highlights its efficiency for UV to IR optical systems. (Refer to the included graphs for visual representation.)

LiF crystals can be customized with the following coatings to enhance their performance:

| Dimension (mm) | Coating | SKU | Price (USD) |

|---|---|---|---|

| 20 × 20 × 5 | Uncoated | 7301 | 150 |

| 30 × 30 × 5 | AR Coating @ 0.3–4.5 μm | 7302 | 180 |

| 40 × 40 × 10 | AR Coating @ UV | 7303 | 220 |

| 50 × 50 × 10 | Custom | 7304 | 250 |