COT offers comprehensive infrared optics system design, delivering customized solutions for precision and performance in various infrared applications.

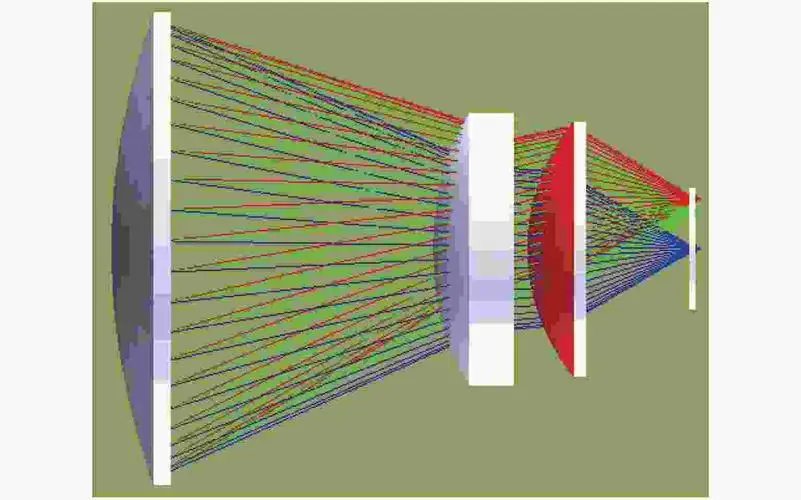

COT provides tailored infrared optics design services, focusing on creating high-performance optical systems that operate efficiently across the infrared spectrum. Our design process involves the careful selection of materials and optical components to maximize transmission and minimize loss, ensuring the system meets specific application requirements. Whether for imaging, sensing, or thermal applications, our infrared optics designs are built for reliability and clarity.

Incorporating thermal considerations into optical designs is critical for maintaining system performance and longevity. COT’s opto-thermal design services address these challenges by integrating thermal management strategies into the optical design process. By simulating and optimizing heat dissipation and temperature control, we ensure that the optical systems perform consistently under various environmental conditions, reducing the risk of thermal-induced failures.

Our thermal engineering services focus on the precise control of thermal dynamics within optical systems. By applying advanced thermal analysis and engineering techniques, COT can design systems that effectively manage heat load, enhance thermal stability, and improve overall system reliability. These services are crucial for applications requiring precise temperature control, such as in thermal imaging and infrared detection.

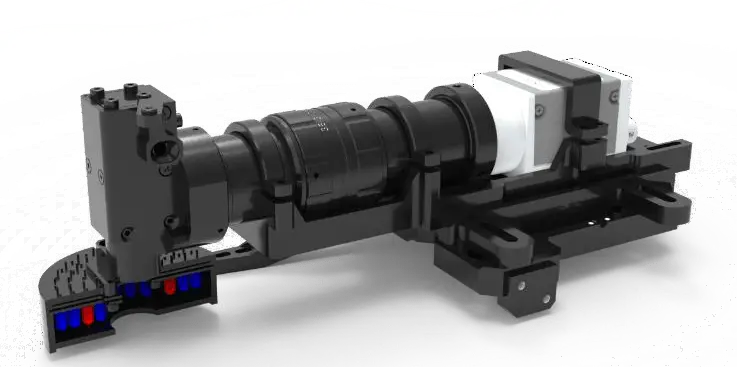

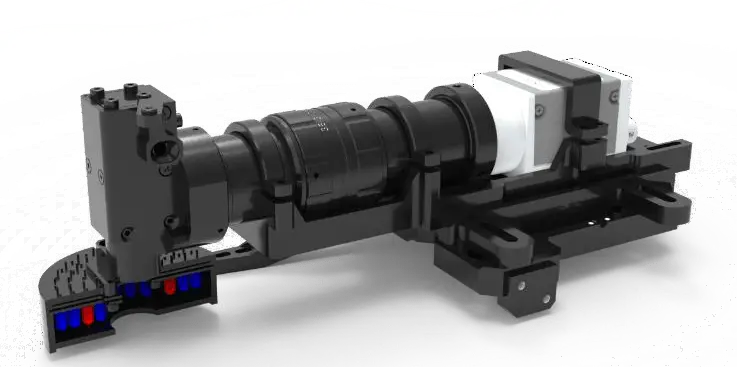

COT excels in the manufacturing of thermal imaging systems, using state-of-the-art technologies to produce high-quality, reliable products. Our manufacturing process includes the assembly and integration of optical, thermal, and electronic components, ensuring that each system is fully optimized for performance. With a focus on quality and precision, COT delivers thermal imaging systems that meet the stringent demands of various industries.

COT provides expert thermal consultation services to optimize the performance and reliability of infrared optical systems.

Our reverse-optical engineering services involve analyzing and deconstructing existing optical systems to improve or replicate their design. This process is essential for updating older systems, troubleshooting performance issues, or developing new systems based on proven designs. COT’s expertise ensures that the reverse-engineered systems meet or exceed the performance of the original.

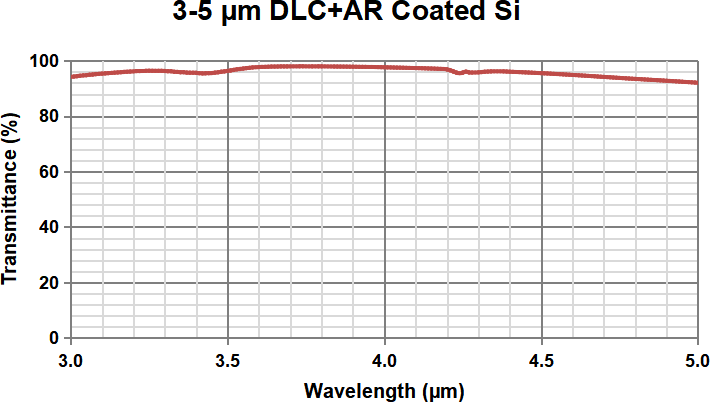

COT offers specialized infrared optical coating services to enhance the performance of optical components. Our coatings are designed to increase transmission efficiency, reduce reflectivity, and provide protection against environmental factors. By applying advanced coatings, we improve the durability and functionality of optical systems, ensuring they operate optimally across the infrared spectrum.

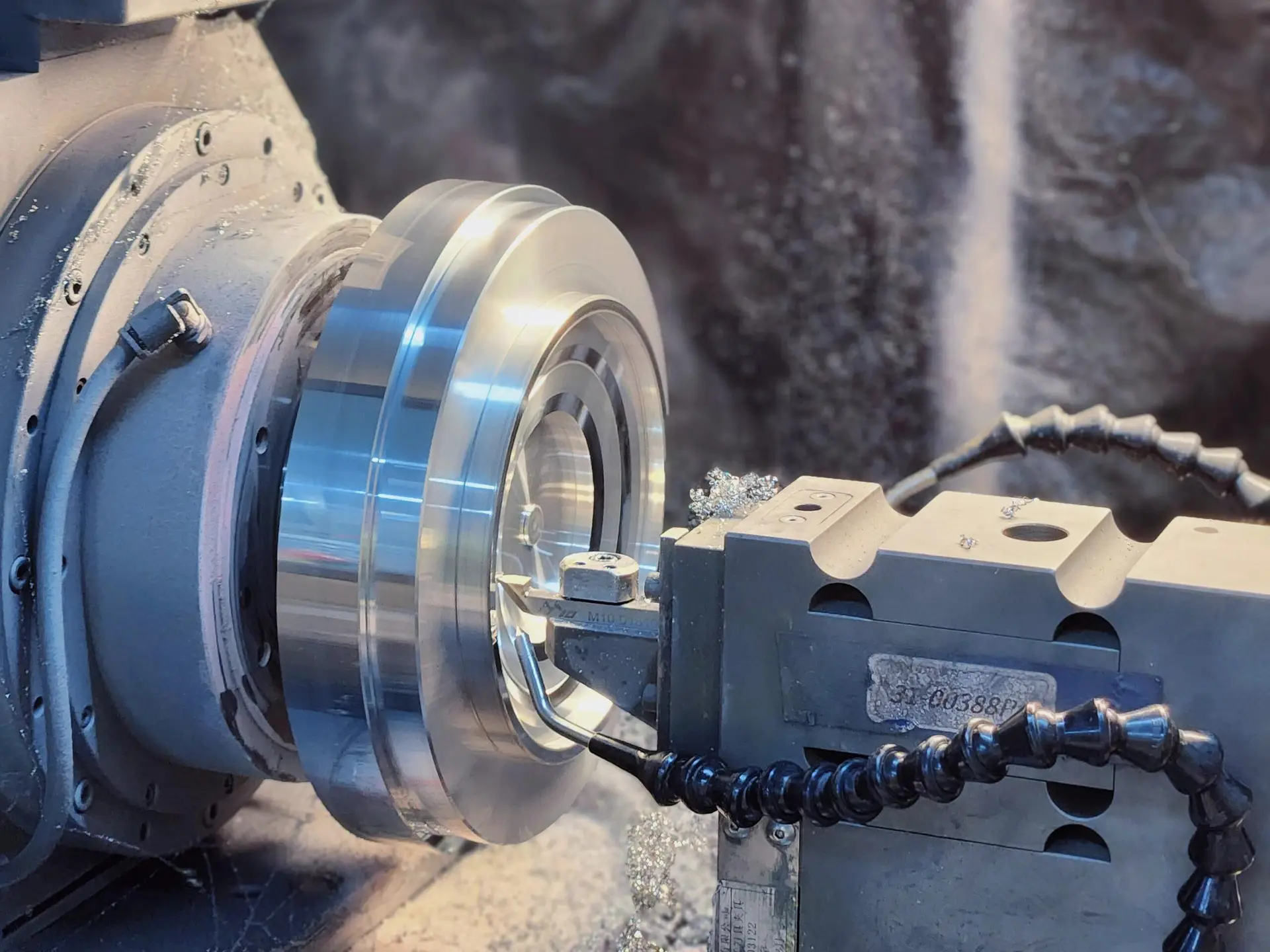

To accelerate the development cycle, COT provides rapid prototyping services for infrared optics. This allows clients to quickly test and refine their designs before moving to mass production. Our rapid prototyping capabilities include precision machining and assembly, enabling us to deliver high-quality prototypes that closely match the final product specifications.

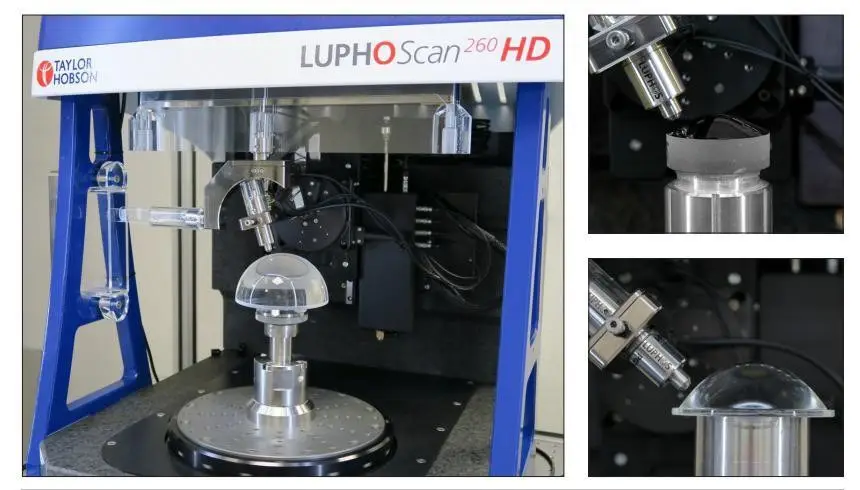

Ensuring the accuracy and reliability of thermal systems is critical. COT’s metrology and quality assurance services provide comprehensive testing and validation of infrared optical systems. Using advanced measurement tools and techniques, we assess the performance of optical components and systems, ensuring they meet the highest standards of quality and precision.