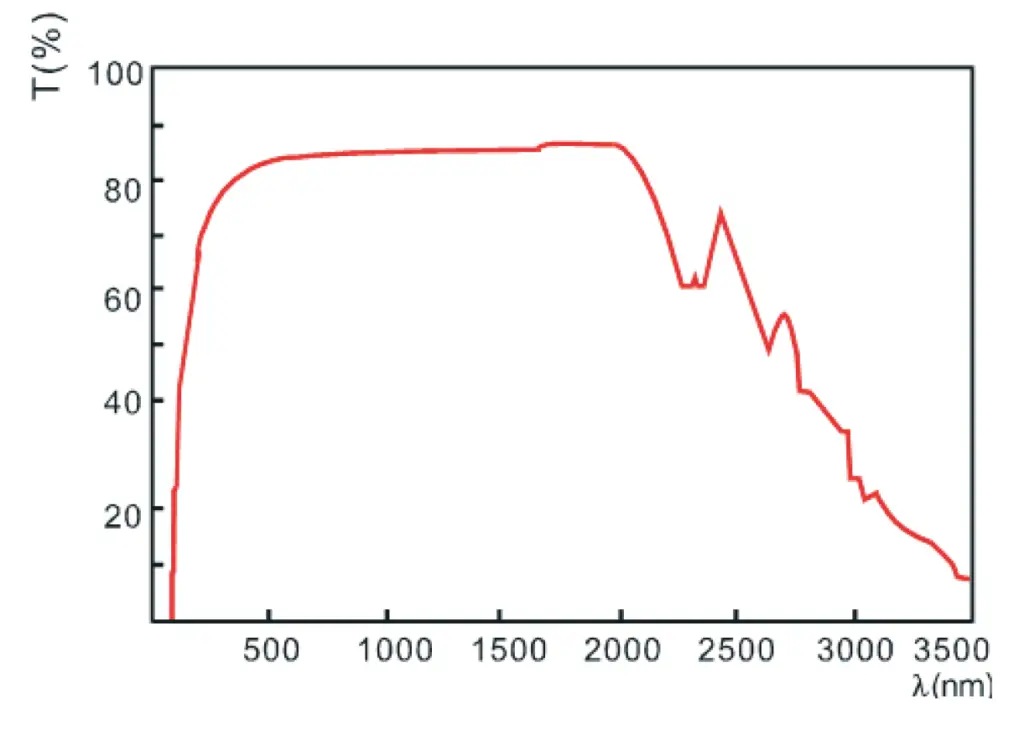

Alpha-Barium Borate (a-BBO, BaB2O4) is a negative uniaxial crystal with a broad transparency range extending from UV (190 nm) to IR (3500 nm). Its large birefringence and low absorption make it an excellent choice for UV and high-power laser applications. a-BBO is mechanically and thermally stable, offering advantages in environments requiring high durability. However, due to its central symmetry, a-BBO does not exhibit nonlinear optical properties and is not suitable for nonlinear laser operations.

a-BBO Crystal is widely used for optical elements like polarizers, wave plates, and other UV optical components, where birefringence and high transmission are essential.

The a-BBO crystal serves critical roles in numerous high-precision and high-power optical applications, including:

| Property | Value |

|---|---|

| Crystal Structure | Trigonal |

| Transparency Range | 190 nm – 3500 nm |

| Density | 3.85 g/cm³ |

| Hygroscopic Susceptibility | Low |

| Mohs Hardness | 4.5 |

| Thermal Expansion Coefficient | -9.3 × 10^-6/°C (C-axis) |

| -9.5 × 10^-6/°C (A-axis) | |

| Damage Threshold | >1 GW/cm² |

| Refractive Indices (532 nm) | nₑ = 1.6776, nₒ = 1.5534 |

| Refractive Indices (1064 nm) | nₑ = 1.6579, nₒ = 1.5379 |

| Sellmeier Equation (A in μm) | n² = 2.7471 + 0.01878/(λ² – 0.01822) – 0.01354λ² |

| Property | Value |

|---|---|

| Birefringence | High |

| UV Transmittance | >90% |

| Refractive Index Range | Varies with wavelength |

| Damage Threshold | >1 GW/cm² for high-power lasers |

| Applications | UV spectrometers, wave plates |

| Specification | Value |

|---|---|

| Size | Aperture up to <50 mm and length up to 40 mm |

| Surface Quality | 10/5 to MIL-PRF-13830B |

| Flatness | 1/4 @ 633 nm |

| Optical Axis Orientation | ±6 arc min |

| Parallelism | 20 arc sec |

| Clear Aperture | >90% |

The transparency curve highlights high UV transmittance across 190-3500 nm, with minimal absorption losses, making it suitable for UV and IR applications.

| Face Dimensions | Length | Coating | Price (USD) |

|---|---|---|---|

| 10 × 10 mm² | 20 mm | AR-coated (UV) | Request |

| 20 × 20 mm² | 30 mm | P-coated (532) | Request |

| Custom | Custom | Custom Coatings | Request |