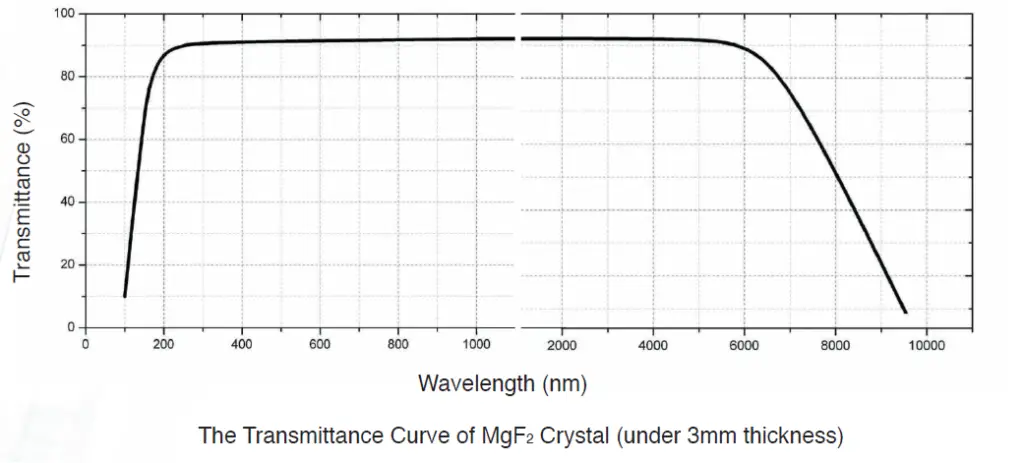

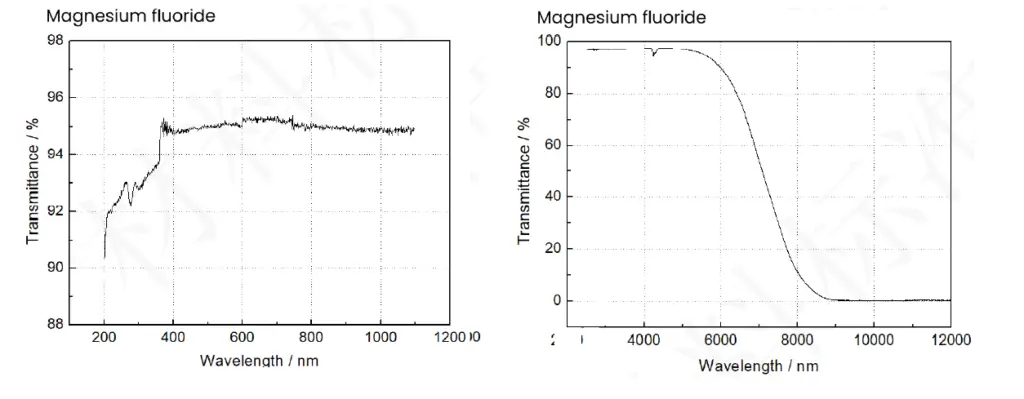

Magnesium Fluoride (MgF₂) is a birefringent crystal with exceptional optical properties, making it an essential material in scientific and technological applications. Its broad transparency range (110 nm to 7.5 µm) ensures efficient performance across the ultraviolet (UV), visible, and infrared (IR) regions. MgF₂ is commonly utilized for its high transmittance, particularly at the 193 nm wavelength for ArF excimer laser applications. Additionally, its low refractive index, isotropy, and durability make it a preferred choice for lenses, windows, and prisms in demanding optical systems. With its excellent hardness and resistance to thermal and mechanical shock, MgF₂ is a versatile crystal for both industrial and high-precision scientific equipment.

MgF₂ Crystals are widely used in the following applications:

Examples:

| Property | Value |

|---|---|

| Density (g/cm³) | 3.18 |

| Melting Point (°C) | 1255 |

| Thermal Conductivity | 0.3 W/m·K at 300 K |

| Thermal Expansion (°C⁻¹) | 13.7 x 10⁻⁶ (c-axis), 8.9 x 10⁻⁶ (⊥ c-axis) |

| Knoop Hardness | 415 (100g indenter) |

| Refractive Index (n₀, nₑ) | n₀ = 1.37608; nₑ = 1.38771 at 0.7 µm |

| Crystal Structure | Tetragonal |

| Cleavage Plane | (110) |

| Specific Heat Capacity | 1003 J/Kg·K |

| Poisson Ratio | 0.276 |

| Property | Value |

|---|---|

| Transparency Range | 110 nm to 7.5 µm |

| Transmittance | >90% @ 0.193 – 6 µm |

| Reflection Loss | 5.2% @ 0.6 µm (both surfaces) |

| dn/dT (°C⁻¹) | 2.3 x 10⁻⁶ (c-axis); 1.7 x 10⁻⁶ (⊥ c-axis) |

| Absorption Coefficient | 0.04 cm⁻¹ @ 2.7 µm |

| Specification | Value |

|---|---|

| Maximum Diameter | 170 mm |

| Clear Aperture | >85% |

| Surface Flatness | λ/4 @ 633 nm |

| Surface Quality | 20/10 |

| Wavefront Distortion | <λ/4 @ 633 nm |

| Chamfer | <0.25 mm x 45° |

| Length Tolerance | ± 0.1 mm |

The transmittance of MgF₂ exceeds 90% across a wide spectrum from UV (110 nm) to IR (7.5 µm). Below are the transmission curves for MgF₂ (3 mm thickness):

MgF₂ crystals can be coated with anti-reflective coatings for enhanced transmittance and reflection reduction. Available coatings include:

| Dimensions | Length | Coating | Price (USD) |

|---|---|---|---|

| 10 mm x 10 mm | 5 mm | AR@193-6 µm | $120 |

| 20 mm x 20 mm | 10 mm | AR@193-6 µm | $220 |

| 50 mm x 50 mm | 15 mm | AR@193-6 µm | $550 |

| Customization | As required | Custom Coating | Quote |