Zinc Selenide (ZnSe) crystal is a transparent yellow material known for its excellent optical transmission properties and low optical absorption in the infrared region. With a transmittance range from 0.55 μm to 20 μm, ZnSe is widely used in CO₂ laser optics, forward-looking infrared (FLIR) systems, and other thermal imaging applications. Its uniform refractive index and low absorption make it an ideal choice for high-power laser systems, medical equipment, and astronomy.

ZnSe crystals are grown through the chemical vapor deposition (CVD) method, ensuring high purity and uniformity for optical applications. Additionally, ZnSe’s mechanical strength and durability make it suitable for demanding applications requiring stable performance under extreme conditions.

| Property | Value |

|---|---|

| Material Grade | CVD ZnSe |

| Maximum Crystal Size | Ø300 mm |

| Growing Method | CVD |

| Density | 5.27 g/cm³ |

| Knoop Hardness | 105 kg/mm² |

| Transmittance Range | 0.55 μm – 20 μm |

| Thermal Expansion | 7.1 × 10^-6 /°C |

| Surface Flatness | λ/8 @ 632.8 nm |

| Surface Quality | 40-20 |

| Clear Aperture | >90% |

| Parallelism | <1′ |

| Bevel Angle | <0.25 × 45° |

| Customization | Available upon request |

| Optical Property | Value |

|---|---|

| Transmission Range | 0.55 μm – 20 μm |

| Refractive Index | n = 2.402 @ 10.6 μm |

| Thermal Conductivity | 18 W/m·K |

| Reflection Loss | <0.2% per surface |

| Damage Threshold | >10 J/cm² @ 10 ns |

| Specification | Value |

|---|---|

| Dimensional Tolerance | ±0.1 mm |

| Surface Flatness | λ/8 @ 632.8 nm |

| Parallelism | <1′ |

| Surface Quality | 40-20 |

| Bevel Angle | <0.25 × 45° |

| Clear Aperture | >90% |

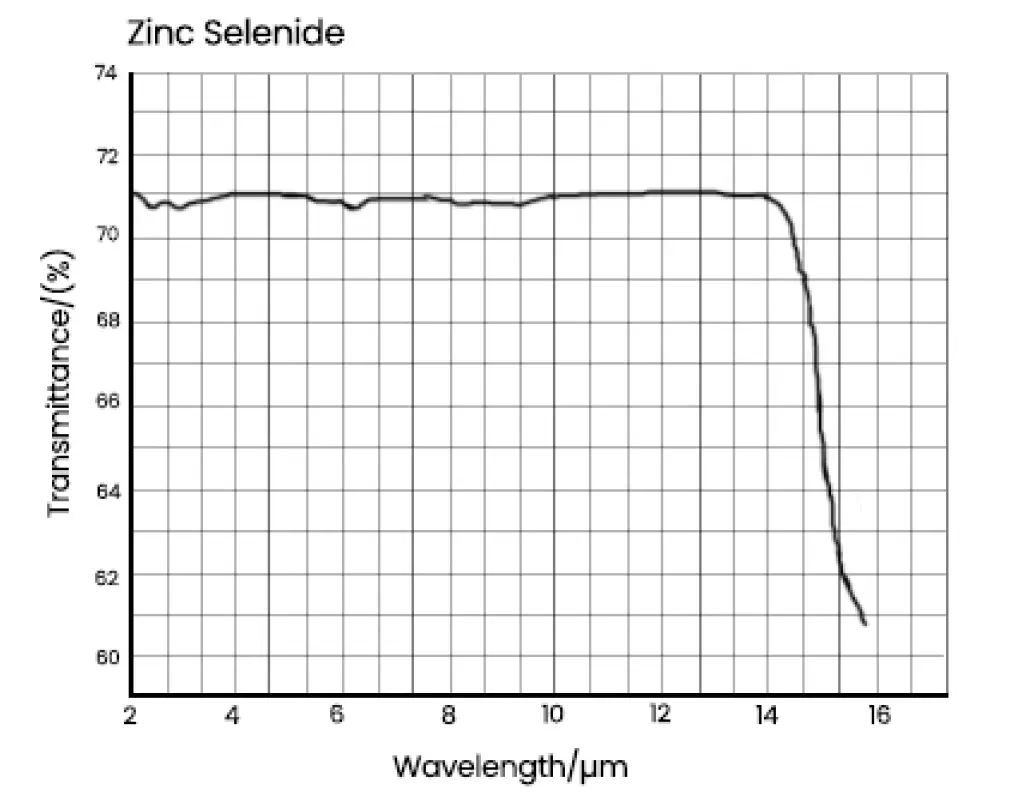

The spectrum transmission curve of ZnSe crystals showcases a broad and efficient transmittance range from 0.55 μm to 20 μm. The curve highlights the material’s ability to maintain over 90% transmittance across this range, making it ideal for applications like CO₂ lasers and thermal imaging

| Size (mm) | Coating | Price (USD) | SKU |

|---|---|---|---|

| 10 × 10 × 1 | AR Coating (2-15 μm) | 300 | ZNSE-1010 |

| 20 × 20 × 2 | AR Coating (2-15 μm) | 450 | ZNSE-2020 |

| 50 × 50 × 2 | AR Coating (2-15 μm) | 700 | ZNSE-5050 |

| Custom Size | Upon Request | TBD | CUSTOM-ZNSE |