Zinc Sulfide (ZnS) crystal is a wide-bandgap semiconductor material that exhibits superior optical transmission across the infrared spectrum (0.37–14 µm). Manufactured using Chemical Vapor Deposition (CVD), ZnS crystals are chemically stable, insoluble in water, and provide moderate density with ease of processing. Their low absorption and high optical uniformity make them the preferred choice for applications requiring advanced IR transparency, such as CO₂ laser optics, thermal imaging systems, and IR windows. The CVD ZnS is further processed with heat treatment to enhance its optical and mechanical properties, ensuring compatibility with high-precision optical systems.

Zinc Sulfide crystals are widely utilized across numerous industries due to their excellent optical and mechanical properties. Some notable applications include:

| Property | Value |

|---|---|

| Optical Transmission Range | 0.37–14 µm |

| Refractive Index | 2.35 @ 10.6 µm |

| Reflection Loss (both surfaces) | ~10% @ 10.6 µm |

| Absorption Coefficient | <0.0005/cm @ 10.6 µm |

| Thermal Conductivity | 27 W/mK |

| Laser Damage Threshold | >3 J/cm² @ 10 ns pulse (1064 nm) |

| Property | Value |

|---|---|

| Optical Transmission Range | 0.37–14 µm |

| Refractive Index | 2.35 @ 10.6 µm |

| Reflection Loss (both surfaces) | ~10% @ 10.6 µm |

| Absorption Coefficient | <0.0005/cm @ 10.6 µm |

| Thermal Conductivity | 27 W/mK |

| Laser Damage Threshold | >3 J/cm² @ 10 ns pulse (1064 nm) |

| Specification | Value |

|---|---|

| Clear Aperture | >90% |

| Surface Flatness | λ/8 @ 632.8 nm |

| Parallelism | <1 arcmin |

| Surface Quality | 40–20 scratch-dig |

| Dimensional Tolerance | ±0.1 mm |

| Chamfering | <0.25 × 45° |

| Coating Options | Available upon request |

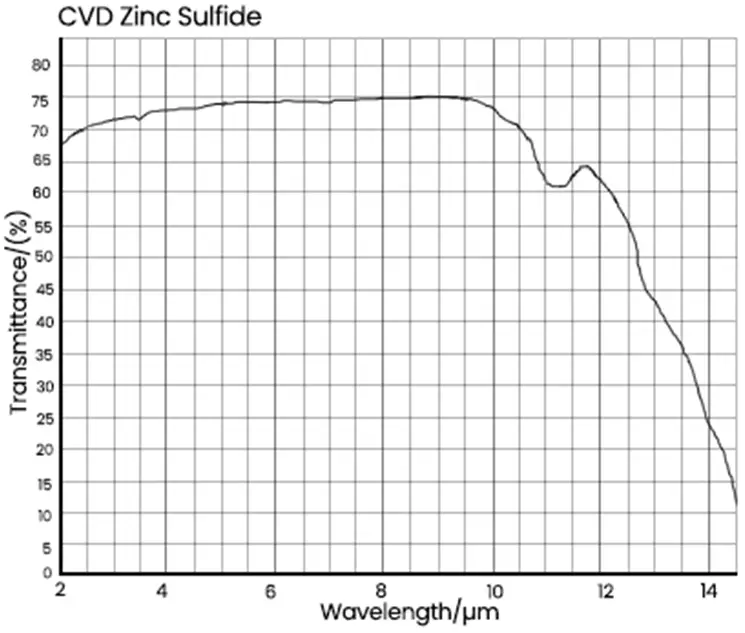

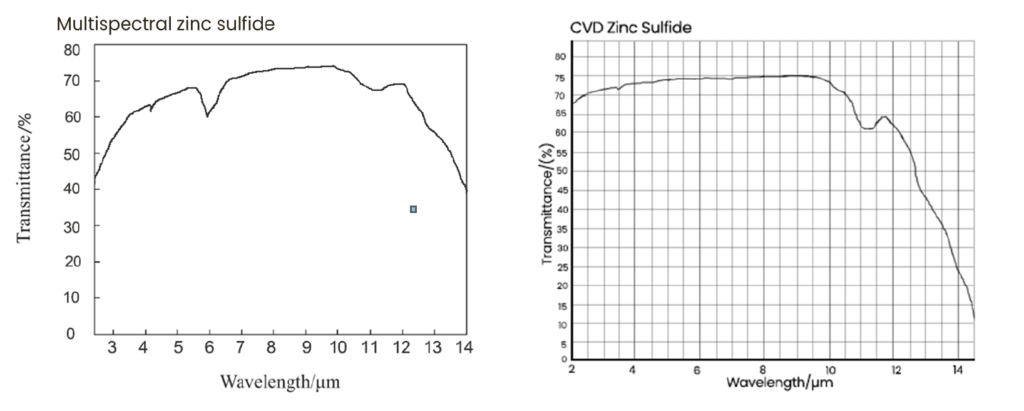

Two spectrum transmission curves demonstrate ZnS’s high transmission properties:

ZnS crystals can be provided with optional anti-reflective coatings to enhance performance for specific wavelengths. Coatings include:

| Dimensions (mm) | Coating | Price (USD) |

|---|---|---|

| 10 × 10 × 2 | Anti-Reflective (AR) | 200 |

| 20 × 20 × 3 | Broadband IR Coating | 350 |

| 25 × 25 × 5 | UV & IR Coating | 400 |

| 50 × 50 × 5 | Customizable | 600 |

| Custom Dimensions | Upon Request | Contact for Quote |