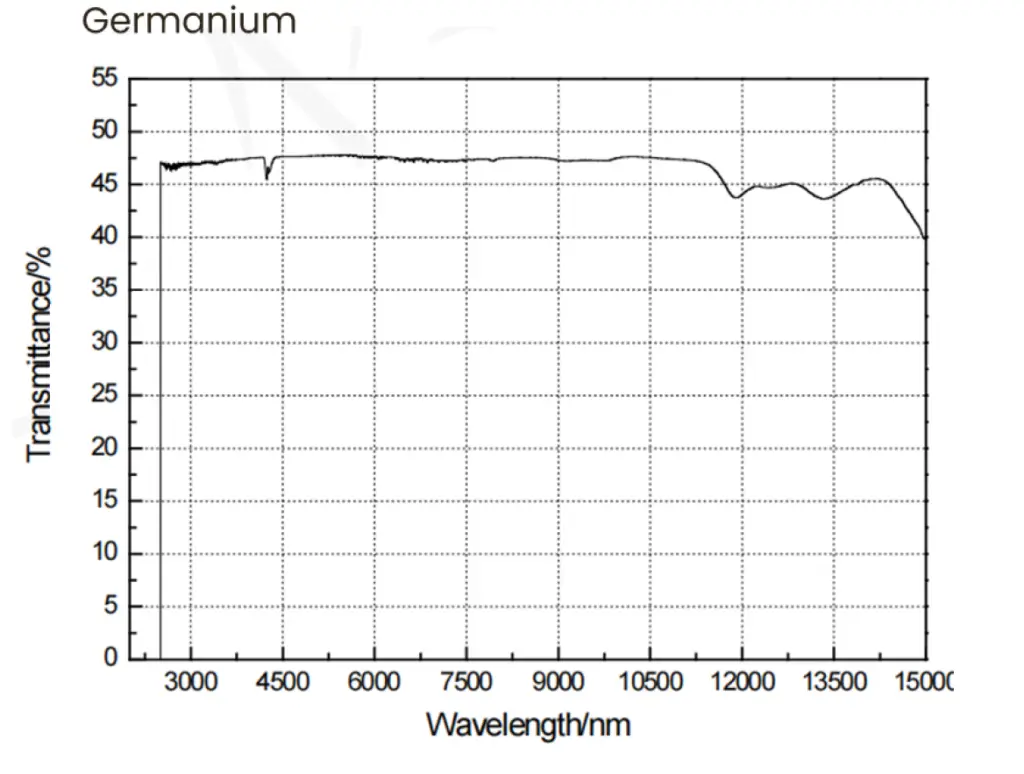

Germanium Crystal (Ge) is a chemically inert optical material with excellent transmission in the infrared spectral range of 2–12 μm. Its high hardness and thermal conductivity make it a preferred choice for demanding applications, including infrared thermal imaging systems, spectrometers, and CO₂ laser optics. With a minimal absorption at 10.6 μm, Germanium Crystal is ideal for use in CO₂ laser windows and output coupling mirrors. It also serves as a base material for infrared filters, including anti-reflective (ATR) applications. Germanium’s high refractive index allows it to operate efficiently in 50% beam-splitting systems without the need for additional coatings.

Germanium Crystals are widely used across a range of applications:

| Property | Value |

|---|---|

| Density | 5.33 g/cm³ |

| Hardness | Mohs scale: 6–6.5 |

| Thermal Conductivity | 59 W/m·K |

| Thermal Expansion Coefficient | 5.8 × 10^-6 /°C |

| Melting Point | 937°C |

| Crystal Structure | Diamond Cubic |

| Cleavage Plane | <111> |

| Common Crystal Orientation | <111>, <100>, <110> |

| Property | Value |

|---|---|

| Transmission Range | 2–12 μm |

| Refractive Index | n = 4.002 (at 10.6 μm) |

| Absorption Coefficient | <0.027 cm^-1 at 10.6 μm |

| Reflective Loss | 53% (both surfaces, uncoated) |

| dn/dT (Thermal Coefficient) | 396 × 10^-6 /°C |

| Lattice Constant | 5.658 Å |

| Specification | Value |

|---|---|

| Surface Flatness | λ/4 @ 632.8 nm |

| Surface Quality | 40-20 scratch-dig |

| Clear Aperture | >90% |

| Chamfer | <0.25 mm × 45° |

| Length Tolerance | ±0.1 mm |

| Thickness Tolerance | ±0.1 mm |

| Parallelism | <1′ |

Germanium Crystal demonstrates excellent transmission from 2 μm to 12 μm, with very low absorption losses around 10.6 μm. Transmission efficiency improves significantly with anti-reflective (AR) coatings.

| Dimensions (mm) | Coating | Price (USD) | SKU |

|---|---|---|---|

| 25 × 2 | AR @ 10.6 μm | 150 | GE25AR |

| 50 × 5 | AR @ 10.6 μm | 280 | GE50AR |

| 75 × 10 | AR @ 10.6 μm | 450 | GE75AR |

| Custom Size | On request | On request | CUSTOM |