Sapphire Crystal, scientifically known as single-crystal aluminum oxide (Al2O3), is one of the hardest and most durable materials available for advanced photonics applications. Its unique combination of chemical, thermal, and optical properties makes it a top choice for extreme environments and precision optics. Sapphire exhibits high transmission from the ultraviolet (UV) through to the infrared (IR) range, with remarkable resistance to mechanical wear, chemical reactions, and thermal expansion. Its hexagonal crystal structure (trigonal system) ensures excellent anisotropic properties, enhancing its performance across diverse industrial applications.

Sapphire Crystals are extensively used in the following industries due to their extraordinary properties:

| Property | Value |

|---|---|

| Chemical Formula | Al2O3 |

| Density | 3.97 g/cm³ (25°C) |

| Hardness | 9 (Moh’s scale) |

| Melting Point | 2053°C |

| Flexural Strength | 1035 MPa (parallel to C-axis, 25°C) |

| Thermal Expansion Coefficient | 8.8 × 10^-6 /°C (parallel to C-axis) |

| Young’s Modulus | 435 GPa (parallel to C-axis, 25°C) |

| Dielectric Constant | 11.5 (parallel to C-axis, 25°C) |

| Refractive Index | 1.768 (ordinary ray); 1.760 (extraordinary ray) |

| Birefringence | 0.008 |

| Crystal System | Trigonal |

| Property | Value |

|---|---|

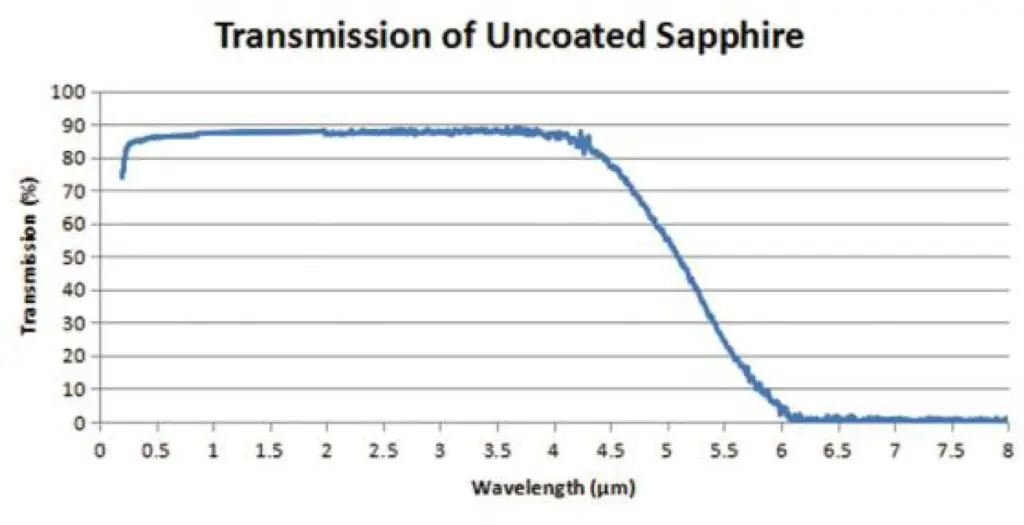

| Transparency Range | 0.15–5.5 µm |

| Optical Anisotropy | Uniaxial Negative |

| Refractive Index (Visible Range) | No = 1.768; Ne = 1.760 |

| Absorption Coefficient | 0.1–0.2 cm^-1 (0.66 µm, 1600°C) |

| Spectral Emittance | 0.1 (at 1600°C) |

| Specification | Value |

|---|---|

| Orientation | C-axis preferred |

| Surface Quality | 40/20 to 10/5 (scratch-dig rating) |

| Surface Finish | Polished or fine-ground |

| Dimensional Tolerances | ±0.01 mm |

| Maximum Size | Up to 300 mm diameter |

Sapphire exhibits high transmission rates over a broad wavelength range. Detailed spectral transmission curves can be supplied on request, highlighting the transparency from UV to IR wavelengths.

| Product | Dimension Range | Price (USD) |

|---|---|---|

| Sapphire Windows | Up to 300 mm diameter | $500–$5,000 |

| Sapphire Rods | 10–50 mm diameter | $300–$1,500 |

| Sapphire Tubes | Custom dimensions | $700–$3,000 |

| Sapphire Lenses | 20–100 mm diameter | $1,000–$10,000 |

| Customization Options | Available on request | Contact for quote |