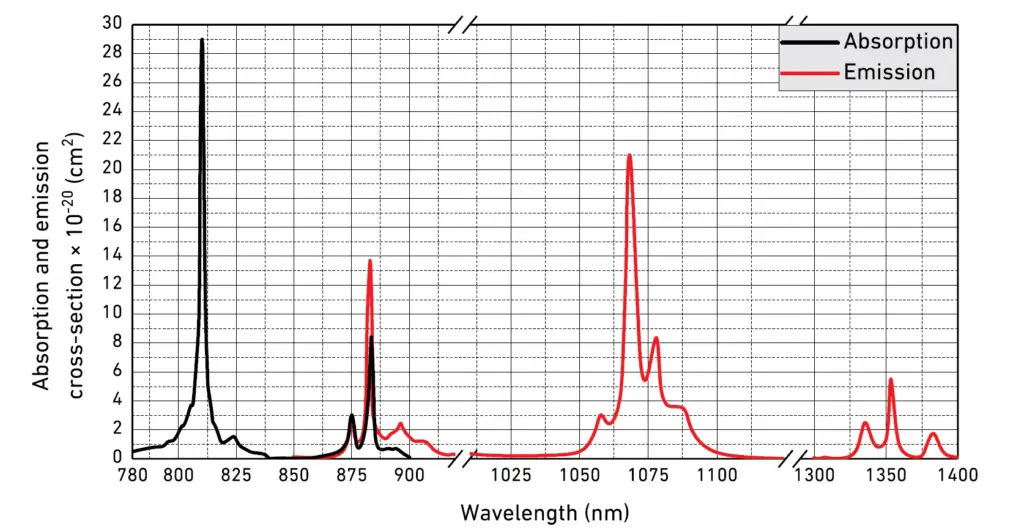

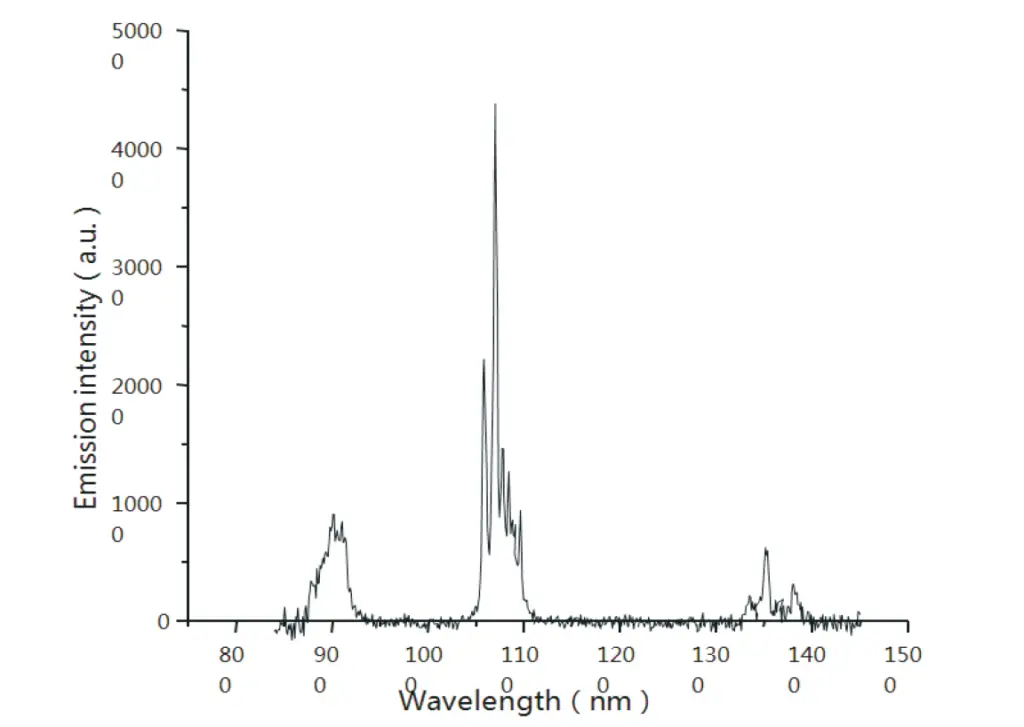

Neodymium Doped Potassium Gadolinium Tungstate (Nd:KGW) is a monoclinic crystal known for its exceptional laser gain properties. Its unique chemical structure minimizes the quenching effects of Nd³⁺ ions, enabling higher doping concentrations and improved fluorescence efficiency. The absorption band at 808 nm (12 nm FWHM) aligns well with commercial diode lasers, providing efficient pumping and low laser threshold.

The material’s thermal conductivity, stability under high-power conditions, and broad emission bandwidth make it ideal for diode-pumped solid-state lasers. Additionally, Nd:KGW can function as a Raman converter for generating secondary wavelengths. These characteristics ensure its wide adoption in industrial, medical, and scientific laser systems.

1. Industrial Applications

| Property | Value |

|---|---|

| Crystal Structure | Monoclinic |

| Space Group | c₂/c (C2/c) |

| Lattice Parameters | a = 8.087 Å, b = 10.374 Å, c = 7.588 Å |

| Density | 7.27 g/cm³ |

| Refractive Index (at 1067 nm) | nₓ = 2.049, nᵧ = 1.978, nᶻ = 2.014 |

| Mohs Hardness | 5 |

| Melting Point | 1075 °C |

| Thermal Conductivity | Kₓ = 2.6 W/m·K, Kᵧ = 3.8 W/m·K, Kᶻ = 3.4 W/m·K |

| Young’s Modulus | 115.8 GPa (Eₓ), 92.4 GPa (Eᵧ) |

| Thermal Expansion Coefficient | αₓ = 4 × 10⁻⁶/K, αᵧ = 1.6 × 10⁻⁶/K, αᶻ = 8.5 × 10⁻⁶/K |

| Property | Value |

|---|---|

| Emission Wavelength | 1070 nm |

| Stimulated Emission Cross-Section | 1.48 × 10⁻¹⁹ cm² |

| Fluorescent Lifetime | 110 µs (3% doping), 90 µs (8% doping) |

| Absorption Bandwidth | 14 nm |

| Absorption Cross-Section | 1.28 × 10⁻¹⁹ cm² |

| Gain Bandwidth | 15 nm |

| Pump Wavelength | 808 nm (FWHM 12 nm) |

| Refractive Index | nₓ = 2.049, nᵧ = 1.978, nᶻ = 2.014 |

| Specification | Value |

|---|---|

| Orientation | [010] |

| Standard Dopant Concentration | Nd: 3%, 5%, 8% |

| Maximum Length | 50 mm |

| Dimensional Tolerance | Diameter: ±0.1 mm, Length: ±0.5 mm |

| Surface Quality (Scratch/Dig) | 20/10 |

| Surface Flatness | λ/6 @ 633 nm |

| Parallelism | <20 arc seconds |

| Perpendicularity | <15 arc minutes |

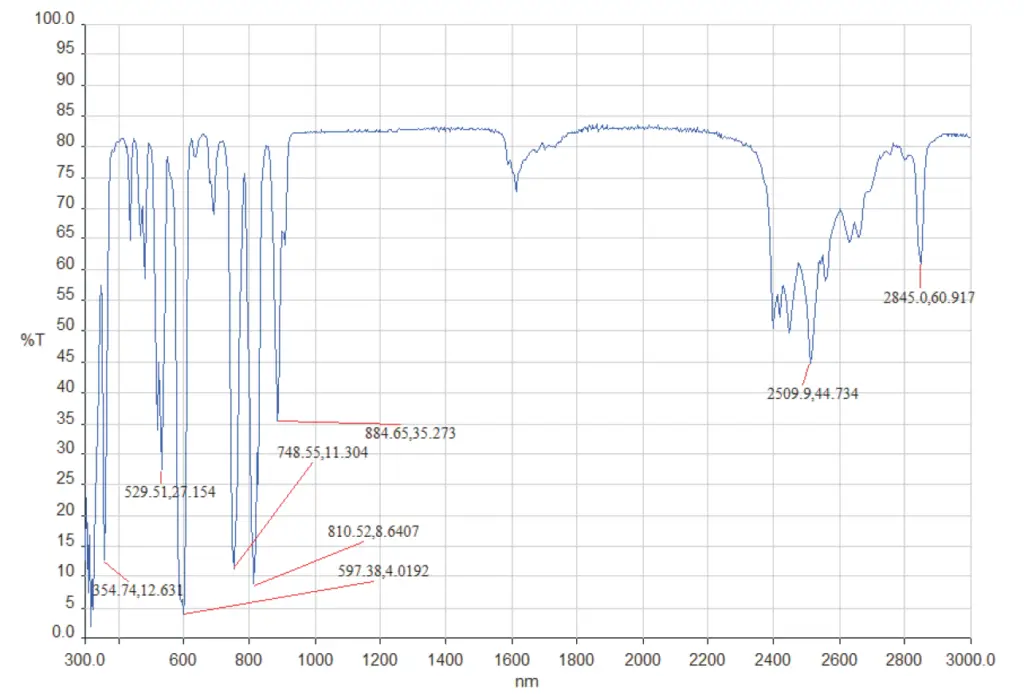

Nd:KGW demonstrates excellent transmission efficiency from visible to near-infrared wavelengths. The graph below illustrates the crystal’s transparency curve, indicating strong absorption at 808 nm and emission at 1070 nm.

| Coating Type | Specifications |

|---|---|

| AR Coating | R < 0.2% at 808 nm, R < 0.15% at 1067 nm |

| Custom Coatings | Available upon request |

| Dimensions (mm) | Length (mm) | Doping | Coating | SKU | Price (USD) |

|---|---|---|---|---|---|

| 3 × 3 | 5 | 3% | AR@808-1067 nm | 7798 | $480 |

| 3 × 3 | 60 | 3% | AR@1067 nm | 7800 | Request Quote |

| 3 × 3 | 5 | 5% | AR@808-1067 nm | 7796 | $480 |

| 3 × 3 | 5 | 5% | Uncoated | 7797 | $420 |

| Custom | Custom | Custom | Customizable | Custom | Request Quote |