Nd:YLF Crystal is a widely used laser material in solid-state laser systems, especially for continuous-wave and pulsed operations at 1047 nm and 1053 nm. Its tetragonal structure and wide transparency range make it suitable for both fundamental and higher harmonic generations. The lower thermal conductivity compared to Nd:YAG results in reduced thermal distortions, achieving superior beam quality.

Nd:YLF Crystal is grown using the precise Czochralski method to ensure excellent quality and minimal scattering losses. These qualities make it ideal for high-energy and high-precision laser systems in industries such as medical, scientific research, and manufacturing

Nd:YLF Crystals are ideal for numerous laser applications, including:

Nd:YLF Crystal also offers self-polarization for certain orientations, making it particularly useful in resonators and high-precision applications.

| Property | Value |

|---|---|

| Chemical Formula | LiY₁.₀NdF₄ |

| Crystal Structure | Tetragonal |

| Lattice Constants | a = 5.16, c = 10.85 |

| Nd Concentration | ~1.4 x 10²⁰ for 1% Nd doping |

| Density | 3.99 g/cm³ |

| Melting Point | 819°C |

| Hardness | 300 Knoop |

| Thermal Expansion Coefficient | 8.3 x 10⁻⁶ parallel c-axis |

| Thermal Conductivity | 0.063 W/cm·K |

| Specific Heat | 0.79 J/g·K |

| Property | Value |

|---|---|

| Transparency Range | 180–6700 nm |

| Peak Stimulated Emission Cross Section | 1.2 x 10⁻¹⁹ cm² at 1053 nm |

| Fluorescence Lifetime | 485 μs for 1% Nd doping |

| Scatter Losses | <0.2%/cm |

| Refractive Index (at 1050 nm) | n₀ = 1.448, nₑ = 1.470 |

| Parameter | Specification |

|---|---|

| Orientation | c-cut, a-cut |

| Surface Quality | 10/5 scratch/dig |

| Wavefront Distortion | λ/4 @ 633 nm |

| Flatness | λ/8 @ 633 nm |

| Parallelism | <20 arc sec |

| Perpendicularity | <15 arc min |

| Chamfer | ≤0.2 mm x 45° |

| End Coating | R < 0.2% @ 1047/1053 nm |

| Damage Threshold | >10 J/cm² @ 1047/1053 nm, 10 ns, 10 Hz |

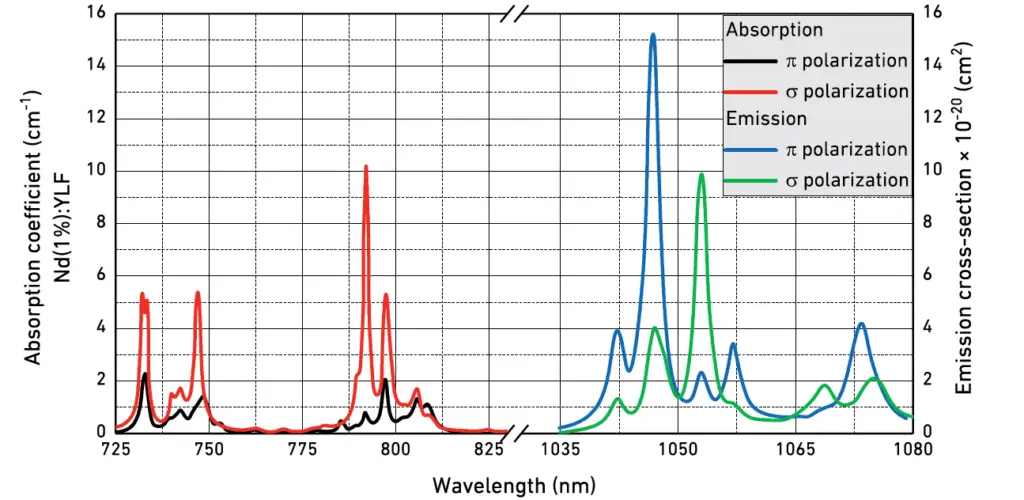

The wide transparency range from UV to near IR is shown in the available data. Absorption peaks at 792 nm and 797 nm correspond to pump wavelengths, while emission peaks align with lasing wavelengths of 1047 nm and 1053 nm. The high transparency in UV and IR makes Nd:YLF suitable for diverse optical systems.

Nd:YLF Crystals can be AR-coated for wavelengths 1047 nm and 1053 nm. Coating options include:

| Face Dimensions | Length | Doping Levels | Coating Options | Price (USD) |

|---|---|---|---|---|

| 3 x 3 mm | 5 mm | 0.4% | AR (R < 0.2% @ 1047/1053 nm) | $450 |

| 10 x 10 mm | 20 mm | 0.7% | AR (R < 0.2% @ 1047/1053 nm) | $600 |

| Custom | Custom | Custom | Custom | Request |