Ytterbium-doped Calcium Fluoride (Yb:CaF2 Crystal) is a cutting-edge laser material offering a combination of low quantum defect and extended fluorescence lifetime. Synthesized using the Czochralski growth technique, Yb:CaF₂ is highly valued for its broad absorption bandwidth and minimal nonlinear effects under intense laser irradiation. These properties make it ideal for ultra-short pulse generation and high-power laser applications. Its cubic crystal structure ensures isotropy, which facilitates uniform optical behavior, and its low thermal expansion coefficient enhances thermal stability.

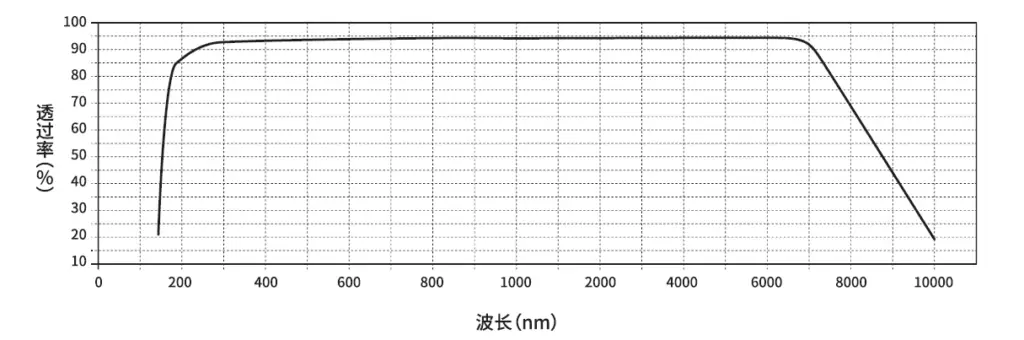

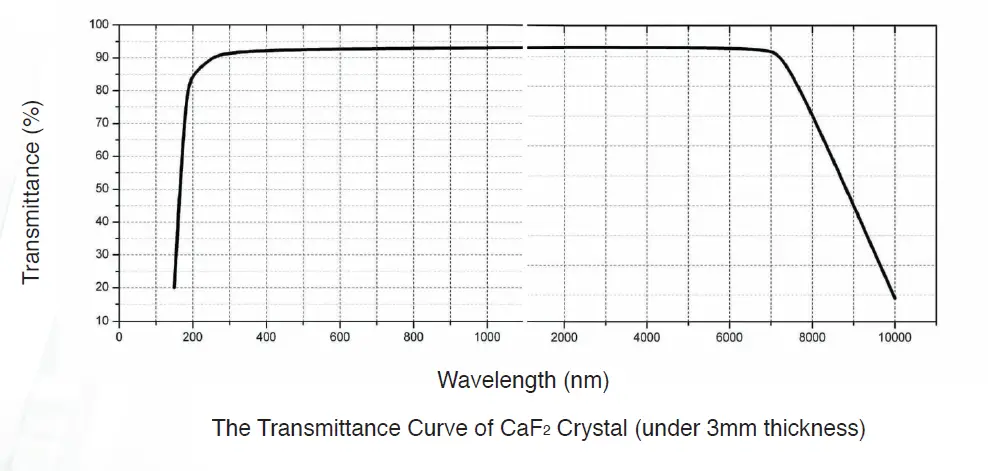

With a wide optical transmission range extending from 0.12 µm to 10 µm, Yb:CaF₂ is well-suited for femtosecond solid-state lasers. Additionally, the material’s low dispersion behavior minimizes phase distortion during laser pulse propagation. These unique properties enable its usage across scientific and industrial applications requiring precision and high energy efficiency.

Yb:CaF₂ crystals find applications in:

For example, Yb:CaF2 Crystal is instrumental in diode-pumped systems generating femtosecond pulses at high average power for industrial and research applications.

| Property | Value |

|---|---|

| Chemical Formula | Yb:CaF₂ |

| Crystal Structure | Cubic |

| Cleavage Plane | (111) |

| Melting Point | 1418 °C |

| Nonlinear Refractive Index | 1.9 × 10^-16 cm²/W |

| Density | 3.18 g/cm³ |

| Thermal Conductivity | 9.71 W/m·K |

| Thermal Expansion Coefficient | 18.41 × 10^-6 K^-1 |

| Mohs Hardness | 4 |

| Property | Value |

|---|---|

| Absorption Peak Wavelength | 979 nm |

| Absorption Cross Section @ 980 nm | 5.4 × 10^-21 cm² |

| Emission Cross Section @ 1035 nm | 2.3 × 10^-21 cm² |

| Fluorescence Lifetime | 2.2 ms |

| Refractive Index @ 1035 nm | 1.42866 |

| Parameter | Value |

|---|---|

| Orientation | (111) |

| Clear Aperture | > 90% |

| Surface Flatness | λ/10 @ 632.8 nm |

| Parallelism Error | < 20 arc sec |

| Perpendicularity Error | < 10 arc min |

| Chamfer | 0.15 mm at 45° |

| Surface Quality (Scratch/Dig) | 10/5 |

| Dimensional Tolerance | Diameter: ±0.1 mm, Length: ±0.5 mm |

The transmission curve reveals high optical transmission in the range of 0.12 µm to 10 µm, showcasing suitability for various wavelength operations.

| Coating Type | Reflection Coefficient |

|---|---|

| AR @ 980 nm–1060 nm | R < 0.2% |

| Custom Coatings | Available on request |

Adhesion Test: Compliant with MIL-C-675C military standards, an adhesion test involved applying a tape that meets LT-90 specifications onto the lens film layer. The tape was affixed fully and then removed vertically. This procedure was performed three times, resulting in no blistering or peeling.

Temperature Test: In line with MIL-C-675C specifications, test pieces were subjected to temperatures of -62±1℃ and 71±1℃. After maintaining them at room temperature (16℃~32℃) for two hours, the adhesion test was repeated, confirming no film detachment.

Abrasion Resistance Test: Conforming to MIL-C-675C and CCC-C-440 standards, the abrasion resistance test involved a gauze tester applying a minimum force of 1.0 lbs (0.45 kg) to the film. This was repeated 25 times with gauze widths of 1/4 inch (6.4mm) and 3/8 inch (9.5mm), ensuring no damage occurred to the film surface.

Humidity Test: Under MIL-C-675C criteria, the test piece was placed in a controlled temperature and humidity chamber set to 49 ±2℃ and 95%~100% humidity for 24 hours. The film remained intact, with no peeling, scratches, or other defects.

Solvent and Cleaning Testing: Following MIL-C-675C specifications, test pieces were exposed to room temperature conditions (16℃~32℃) and tested with acetone and alcohol for at least 10 minutes each. After air drying and subsequent cleaning with a cotton cloth soaked in alcohol, the film surface showed no signs of peeling or scratches.

Salt Spray Test: After 100 hours in a 35°C environment with a 5% saltwater concentration, the film showed no signs of damage.

| Dimensions (mm) | Length (mm) | End Faces | Doping | Coatings | Price (USD) |

|---|---|---|---|---|---|

| 10 × 10 | 10 | Brewster-angle cut | 1% | Uncoated | 590 |

| 10 × 10 | 10 | Right-angle cut | 1% | AR @ 980 nm–1070 nm | 590 |

| 3 × 3 | 5 | Brewster-angle cut | 3% | Uncoated | 590 |

| 3 × 3 | 5 | Right-angle cut | 3% | AR @ 980 nm–1070 nm | 590 |

| Custom | Upon request | Upon request | Custom | Custom | Upon request |