Cr:LiSAF (Chromium-doped Lithium Strontium Aluminum Fluoride) crystals are exceptional laser materials for producing ultra-short pulses and high-energy lasers. The material is characterized by its trigonal crystal structure and high fluorescence efficiency, making it a reliable choice for femtosecond and CPA (Chirped Pulse Amplification) laser systems. Cr:LiSAF crystals offer broad absorption and emission spectra in the near-infrared region, ensuring effective pumping using flash lamps or diode lasers. They feature low nonlinear refractive indices, making them suitable for constructing high-Q cavities with minimal losses. Their tunable wavelength operation and high laser damage threshold position them as an efficient medium for laser development.

Cr:LiSAF crystals are widely utilized in:

| Property | Specification |

|---|---|

| Formula | Cr:LiSAF |

| Crystal Structure | Trigonal (Point Group P31c) |

| Lattice Parameters | a = 5.084 A, c = 10.21 A |

| Melting Point | 766 °C |

| Density | 3.45 g/cm³ |

| Hardness | 4.6 (Mohs Scale) |

| Fracture Toughness | 0.40 (1/c) |

| Thermal Conductivity | 3.3 W/mK (parallel), 3.0 W/mK (perpendicular) |

| Thermal Expansion Coefficient | -10 x 10^-6 K^-1 (parallel), 25 x 10^-6 K^-1 (perpendicular) |

| Specific Heat | 0.842 J/gK |

| Property | Specification |

|---|---|

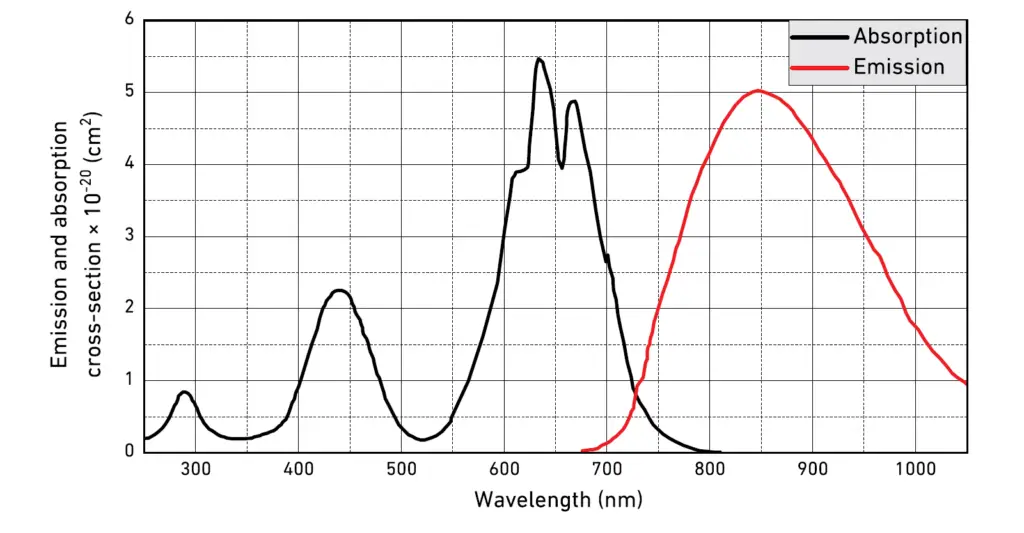

| Emission Peak | 846 nm |

| Absorption Peak | 670 nm |

| Emission Cross Section | 4.8 x 10^-20 cm² |

| Fluorescence Lifetime | 67 µs |

| Scatter Losses | < 0.2%/cm |

| dn/dT (Refractive Index Temp Coeff) | -4.8 x 10^-6 (parallel), -2.5 x 10^-6 (perpendicular) |

| Property | Specification |

|---|---|

| Dopant Concentration | Cr: 0.5–1.0 at.% |

| Surface Quality | 10/5 (MIL-PRF-13830B) |

| Dimensions | Diameter: 2-16 mm, Length: 1-60 mm |

| Flatness | Lambda/8 at 633 nm |

| Parallelism | < 20 arc sec |

| Perpendicularity | < 15 arc min |

| Chamfer | 0.2 mm x 45° |

The spectrum demonstrates broad absorption and emission bands, especially in the 650-900 nm range, suitable for tunable laser operations.

| Dimensions | Length | Dopant | Coating | SKU | Price (USD) |

|---|---|---|---|---|---|

| 5 x 5 mm | 12 mm | 3% | AR@670-1100 nm | 770 | |

| 5 x 5 mm | 12 mm | 3% | Uncoated | 930 |