Er:YAG Crystal (Erbium-doped Yttrium Aluminum Garnet) crystals are renowned for their robust performance in laser systems operating in the near-infrared spectrum, particularly at the 2940 nm wavelength. This wavelength corresponds to the hydroxyl absorption peak, allowing excellent absorption in biological tissues, making Er:YAG Crystal a preferred choice for medical, dental, and surgical laser applications. The cubic symmetry and high thermal conductivity make it thermally stable and highly reliable. The crystals are manufactured to deliver high optical quality and are suitable for both continuous-wave (CW) and pulsed operations, maintaining stable performance even under high thermal loads.

Er:YAG Crystals have diverse applications across multiple fields:

1. Medical and Dental Applications

2. Industrial Applications

3. Military and Remote Sensing

Examples

| Property | Value |

|---|---|

| Chemical Formula | Er:Y3Al5O12 |

| Crystal Structure | Cubic Garnet |

| Dopant Concentration | Er: 50 at.% |

| Density | 4.56 g/cm³ |

| Refractive Index | 1.79 (at 2940 nm) |

| Melting Point | 1970°C |

| Mohs Hardness | 8.5 |

| Thermal Conductivity | 13 W/m·K (at 1064 nm) |

| Thermal Expansion Coefficient | 7.8 × 10^-6 /K |

| Damage Threshold | >500 MW/cm² (1064 nm, 10 ns, 10 Hz) |

| Optical Parameter | Value |

|---|---|

| Laser Wavelength | 2940 nm |

| Photon Energy | 6.75 × 10^-20 J |

| Emission Cross Section | 3 × 10^-20 cm² |

| Refractive Index | 1.79 (at 2940 nm) |

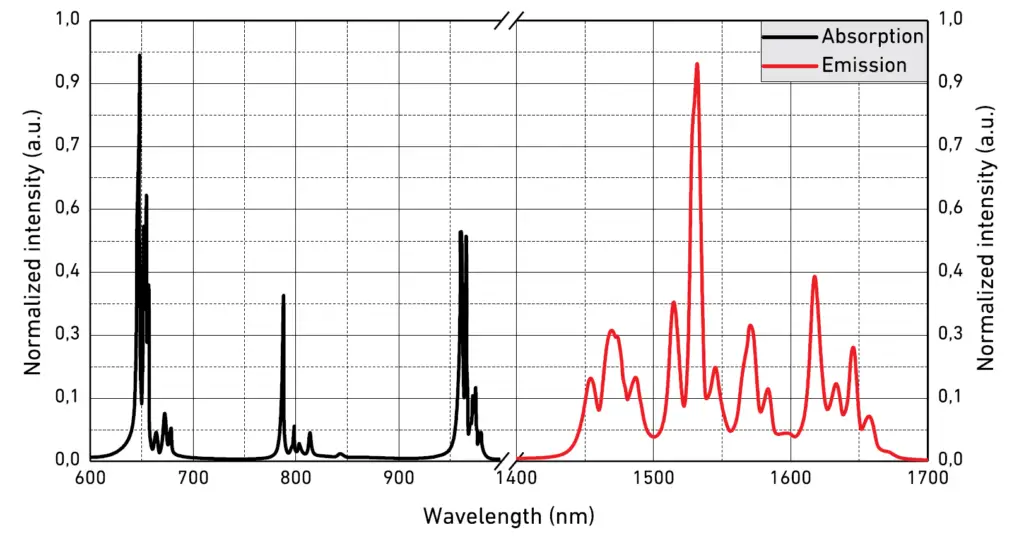

| Pump Bands | 600-800 nm |

| Lifetime of Er Energy Level | 6.0 ms |

| Absorption Peaks | 960, 1470, 1532 nm |

| Parameter | Value |

|---|---|

| Rod Dimensions | Diameter: 3-6 mm; Length: 50-120 mm |

| Surface Quality | 10/5 Scratch/Dig |

| Wavefront Distortion | < λ/8 @ 633 nm |

| Flatness | λ/10 @ 633 nm |

| Parallelism | 20 arc sec |

| Perpendicularity | 15 arc min |

| Chamfer | 0.2 mm × 45° |

| AR Coating | R < 0.2% @ 2940 nm |

For 2940 nm, Er:YAG demonstrates strong absorption near the hydroxyl peak and a broad emission spectrum. Customized absorption and emission curves are available upon request to optimize for specific applications.

| Face Dimensions | Length | End Faces | Doping | Coatings | Price (USD) |

|---|---|---|---|---|---|

| 5 × 5 mm | 3 mm | Brewster-angle cut | 0.15% | Uncoated | Request |

| 5 × 5 mm | 2 mm | Brewster-angle cut | 50% | Uncoated | 500 |

| Customization | As required | Upon request | Up to 50% | Custom coatings | On Request |