Er³⁺/Yb³⁺ co-doped Yttrium Aluminum Borate (Er:Yb:YAB Crystal) crystals are designed for eye-safe laser applications, particularly at 1.55 µm. They offer superior thermal conductivity, high quantum efficiency, and minimal upconversion loss, outperforming alternative materials like phosphate glasses. With excellent transparency to environmental factors such as smoke and atmospheric absorption, Er:Yb:YAB crystals are well-suited for precise applications like LiDAR, 3D imaging, and target recognition. The robust structural integrity and high laser efficiency make it a preferred choice for both continuous wave (CW) and pulsed laser operations.

| Property | Specification |

|---|---|

| Chemical Formula | Er:Yb:YAl(BO₃)₄ |

| Crystal Structure | Trigonal, D₃₂-R32 |

| Atomic Density | 0.55 × 10²⁰ atoms/cm³ (at.% Yb³⁺ or Er³⁺) |

| Mohs Hardness | 7.5 Mohs |

| Density | 3.7 g/cm³ |

| Refractive Index | 1.75 (nᴇ), 1.68 (nᴏ) at 1550 nm |

| Thermal Expansion | 10^-6/K, anisotropic: 2.0 (a-axis), 9.7 (c-axis) |

| Thermal Conductivity | 4.7 W/m/K |

| Parameter | Er:Yb:YAB | Comparison (Phosphate Glass) |

|---|---|---|

| Pumping Wavelength | 976 nm | 976 nm |

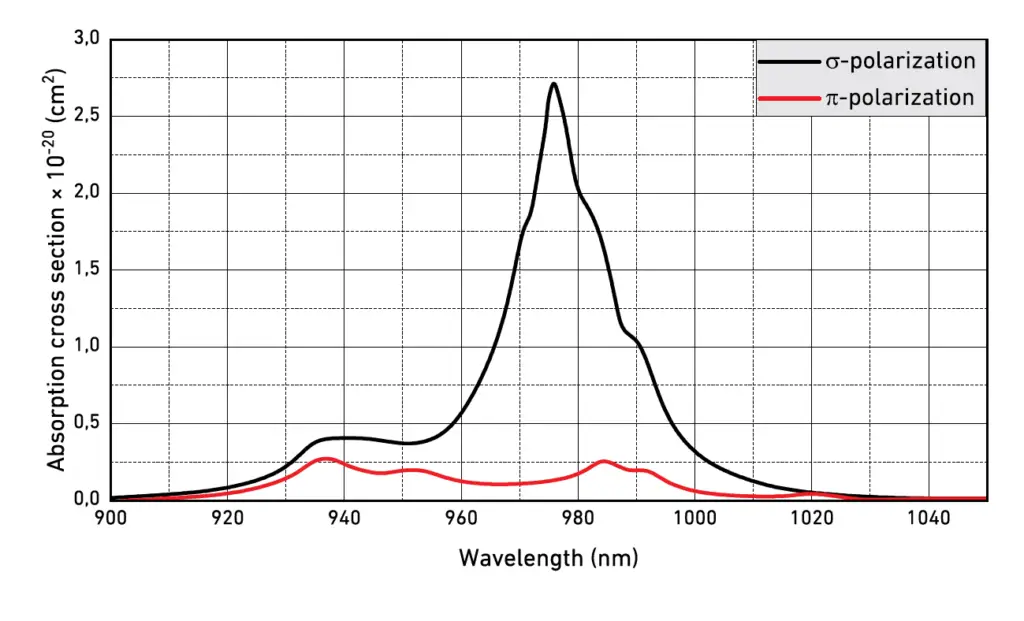

| Peak Absorption Cross-section | 3 × 10^-20 cm² (σ-polarization) | 1 × 10^-20 cm² |

| FWHM of Absorption Band | 19 nm | 10 nm |

| Peak Fluorescence Wavelength | 1530 nm | 1533 nm |

| Emission Cross-section | 2 × 10^-20 cm² | 0.8 × 10^-20 cm² |

| Fluorescence Lifetime | 0.3 ms | 0.8 ms |

| Refraction Index | 1.75 (nᴇ), 1.68 (nᴏ) | 1.54 |

| Maximum Slope Efficiency | >30% | >30% |

| Specification | Value |

|---|---|

| Dopant Concentration | Er³⁺: 0.1–3 at.%, Yb³⁺: 5–30 at.% |

| Dimension Tolerance | ±0.1 mm |

| Surface Quality | 10/5 to MIL-PRF-13830B |

| Wavefront Distortion | <λ/8 at 633 nm |

| Parallelism | <20 arc sec |

| Perpendicularity | <15 arc min |

| Flatness | <λ/8 at 633 nm |

| Chamfer | <0.2 mm × 45° |

Spectrum transmission curves highlight high absorption near 976 nm and strong emission at 1530 nm with minimal overlap, enabling efficient laser operation and high selectivity. Data consolidated indicates high pump efficiency.

| Dimensions | Length | End Faces | Doping | Coating | Price (USD) |

|---|---|---|---|---|---|

| 3 × 3 mm | 1 mm | Brewster-angle cut | 12% Yb³⁺, 1.5% Er³⁺ | AR @ 976 nm + 1480–1600 nm | $540 |

| 3 × 3 mm | 2 mm | Right-angle cut | 12% Yb³⁺, 1.5% Er³⁺ | Uncoated | $540 |

| 3 × 3 mm | 3 mm | Right-angle cut | 12% Yb³⁺, 1.5% Er³⁺ | AR @ 976 nm + 1480–1600 nm | $590 |

| Customization | As required | As required | As required | As required | Request Quote |