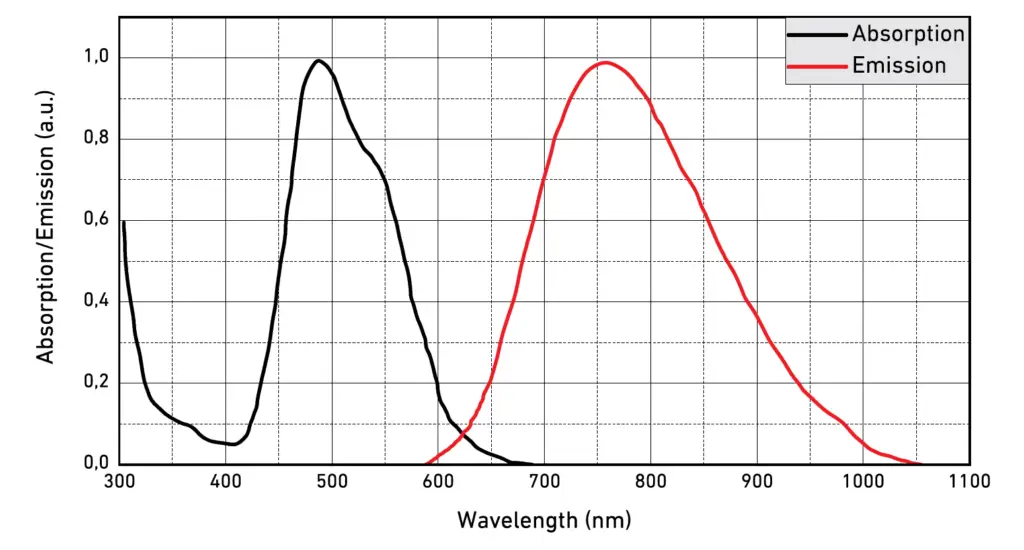

Ti:Sapphire Crystal (Ti³⁺:Al₂O₃) is a titanium-doped sapphire material known for its tunability and high optical gain. It is extensively used in femtosecond mode-locked oscillators and amplifiers, enabling ultrashort pulse generation below 10 fs. Its high thermal conductivity and superior mechanical strength make it suitable for high-power laser applications. Grown using the Temperature Gradient Technique (TGT), the crystal is free of scattering and dislocations, ensuring premium optical quality and high damage thresholds. The absorption band of Ti:Sapphire, centered at 490 nm, allows efficient pumping by Nd:YAG, Nd:YLF, and Nd:YVO₄ lasers.

| Property | Value |

|---|---|

| Chemical Formula | Ti³⁺:Al₂O₃ |

| Crystal Structure | Hexagonal |

| Lattice Parameters | a=4.758 Å, c=12.991 Å |

| Density | 3.98 g/cm³ |

| Melting Point | 2040°C |

| Mohs Hardness | 9 |

| Thermal Conductivity | 52 W/mK |

| Specific Heat | 0.42 J/g·K |

| Thermal Expansion | 8.4 × 10⁻⁶/°C |

| Property | Value |

|---|---|

| Tuning Range | 660 – 1050 nm |

| Absorption Range | 400 – 600 nm |

| Absorption Peak | 488 nm |

| Emission Peak | 795 nm |

| Fluorescence Lifetime | 3.2 μs (T = 300 K) |

| Refractive Index | 1.76 @800 nm |

| Laser Action | 4-Level Vibronic |

| Peak Cross-Section | 3–4 × 10⁻¹⁹ cm² |

| Parameter | Specification |

|---|---|

| Dopant Concentration | 0.06 – 0.26 atm% |

| Diameter | 2 – 30 mm |

| Length | 2 – 30 mm |

| Surface Quality (Scratch/Dig) | 40/20 to MIL-PRF-13830B |

| Flatness | λ/8 @633 nm |

| Wavefront Distortion | λ/4 @633 nm |

| Parallelism | <20 arc sec |

| Perpendicularity | <15 arc min |

| Chamfer | 0.1 mm × 45° |

Absorption and emission spectra confirm strong peaks at 488 nm and 795 nm, respectively, with broad tunability.

| Face Dimensions | Length | End Faces | Coatings | Price (USD) |

|---|---|---|---|---|

| 3 × 3 mm | 5 mm | Brewster-angle cut | Uncoated | $880 |

| 3 × 3 mm | 5 mm | Right-angle cut | AR@532 nm + 750–850 nm | $600 |

| 6 × 6 mm | 15 mm | Brewster-angle cut | Uncoated | $1000 |

| 12 × 12 mm | 25 mm | Right-angle cut | AR@532 nm + 750–850 nm | $2150 |

| 50 × 50 mm | 30 mm | Right-angle cut | Custom Coating Options Available | Request Quote |