Yb:KYW Crystal (Ytterbium-doped Potassium Yttrium Tungstate) is a leading gain medium known for its extensive gain bandwidth and high emission cross-sections. Its properties make it suitable for femtosecond and mode-locked laser systems, achieving ultra-short pulse durations below 100 femtoseconds. Compared to other Yb-doped materials, Yb:KYW exhibits superior performance due to its high doping levels without concentration quenching, enabling reliable high-power output. The thermal conductivity of Yb:KYW ensures stability in high-energy applications, making it an excellent choice for regenerative amplifiers and continuous-wave lasers.

The Yb:KYW Crystal serves as a robust medium in:

Example Application:

A Yb:KYW crystal doped with 5% ytterbium ions can produce a stable output of ultrashort pulses with a center wavelength of 1020 nm, supporting advanced micromachining for nanotechnology and biophotonics.

| Property | Value |

|---|---|

| Chemical Formula | KY(WO4)2 doped with Yb^3+ |

| Crystal Structure | Monoclinic |

| Density | 6.41 g/cm³ |

| Mohs Hardness | 5 |

| Thermal Conductivity | 3–4 W/m·K |

| Thermal Expansion Coefficient | α_a = 9.8 × 10^-6 /°C |

| Doping Levels | 2–10% Yb^3+ |

| Parameter | Value |

|---|---|

| Absorption Peak Wavelength | 444 nm |

| Absorption Cross-section | 8 x 10^-19 cm² |

| Absorption Bandwidth | ~5 nm |

| Emission Wavelengths | 523 nm, 607 nm, 640 nm |

| Emission Cross-section | 20 x 10^-19 cm² |

| Fluorescence Lifetime | 50 µs |

| Parameter | Specification |

|---|---|

| Orientation | Np-cut, Nm-cut, and other orientations available. |

| Clear Aperture | >90% |

| Length Tolerance | ±0.1 mm |

| Surface Flatness | λ/10 @ 632.8 nm |

| Surface Quality | 20-10 scratch/dig |

| LIDT | >10 J/cm² @ 1040 nm, 10 ns |

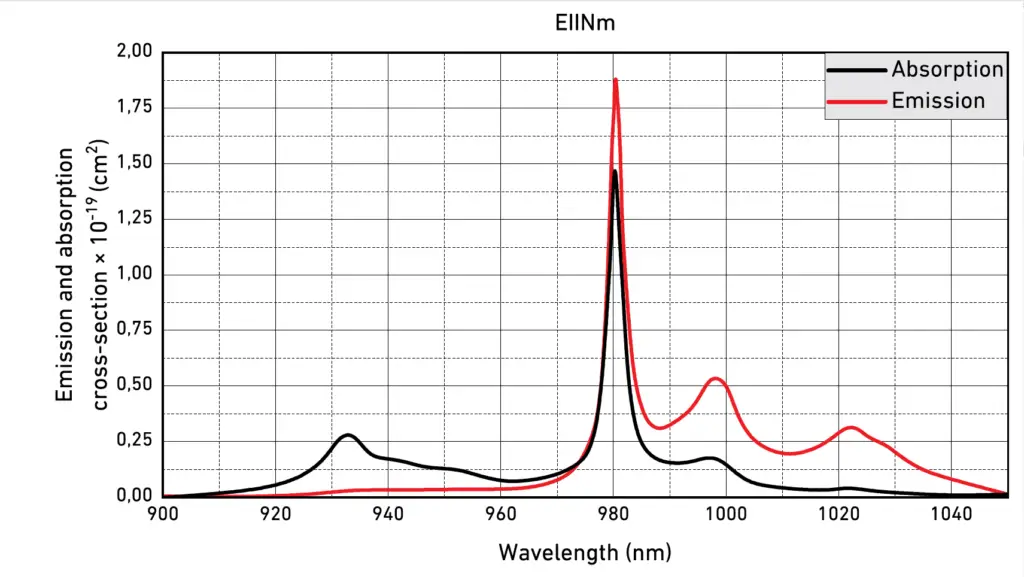

The absorption and emission spectra of Yb:KYW Crystals display strong peaks at 980 nm and 1030 nm, respectively, ensuring efficient energy conversion and high performance in laser systems.

Custom anti-reflective (AR) coatings are available, optimized for:

| Face Dimensions | Length | End Faces | Doping | Coatings | Price (USD) |

|---|---|---|---|---|---|

| 3 × 3 mm | 5 mm | Brewster-angle cut | 2% | AR@970–1070 nm | 540 |

| 5 × 5 mm | 5 mm | Right-angle cut | 10% | AR@970–1070 nm | 590 |

| Customizable | Custom | Customizable | Up to 10% | Customizable | Upon Request |