Yb:YAB (Ytterbium-doped Yttrium Aluminum Borate) crystal is a versatile laser medium featuring self-doubling properties, combining both lasing and nonlinear optical functions. As a uniaxial negative crystal, it enables efficient frequency conversion from infrared to visible regions. Its high Yb doping concentration allows strong emission with minimal quenching, providing exceptional optical performance. Yb:YAB crystals are known for their robust mechanical strength, high thermal conductivity, and stable chemical properties, making them ideal for high-power and compact laser systems. These qualities make the Yb:YAB suitable for applications requiring strong nonlinear optical effects and reliable operation.

| Parameter | Specification |

|---|---|

| Crystal Structure | Trigonal |

| Chemical Formula | Yb:YAl3(BO3)4 |

| Density | 3.84 g/cm³ |

| Mohs Hardness | 7.5 |

| Thermal Conductivity | 6 W/m·K |

| Refractive Index at 632.8 nm | no = 1.7757, ne = 1.7015 |

| Thermal Expansion Coefficient | 2 × 10^-6 /K |

| Typical Doping Level | 10 at.% Yb |

| Absorption Bandwidth at Peak | 20 nm |

| Parameter | Specification |

|---|---|

| Absorption Peak Wavelength | 976 nm |

| Emission Wavelength | 1040 nm |

| Emission Cross-Section | 0.5 × 10^-20 cm² |

| Lifetime of Yb Energy Level | 680 µs |

| Absorption Cross-Section | 3.8 × 10^-20 cm² |

| dn/dT (Refractive Index Change w/Temp) | 1.4 × 10^-6 /K |

| Parameter | Specification |

|---|---|

| Orientation | c-cut |

| Face Dimension Tolerance | ±0.01 mm |

| Length Tolerance | ±0.1 mm |

| Parallelism Error | <20 arcsec |

| Perpendicularity Error | <10 arcmin |

| Protective Chamfers | <0.1 mm at 45° |

| Surface Flatness | λ/10 @ 632.8 nm |

| Laser-Induced Damage Threshold | >10 J/cm² @ 1040 nm, 10 ns |

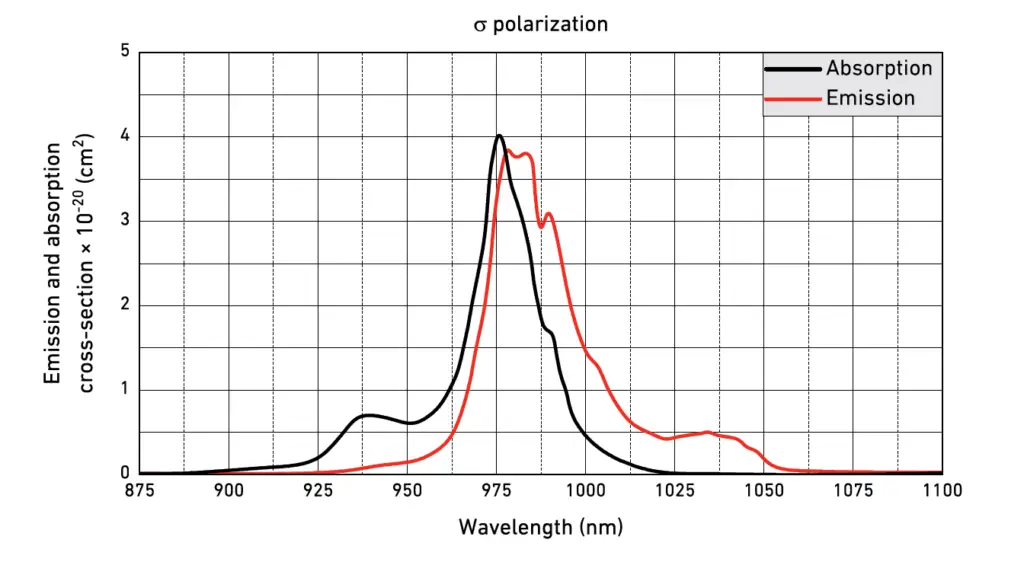

The Yb:YAB crystal exhibits peak absorption at 976 nm and emission at 1040 nm, as shown in the emission and absorption spectra above. Its broad absorption bandwidth allows for versatile pumping options, making it a preferred material for high-power applications.

| Face Dimensions | Length | End Faces | Orientation | Doping | Coatings | Price |

|---|---|---|---|---|---|---|

| 3 x 3 mm | 2 mm | Right-angle cut | c-cut | 10% | AR/AR@960-1060 nm | Request |

| 3 x 3 mm | 2 mm | Brewster-angle cut | c-cut | 10% | Uncoated | Request |

| 3 x 3 mm | 2 mm | Right-angle cut | θ = 31°, φ = 0° | 10% | AR/AR@520-976-1040 nm | Request |