Ytterbium-doped Yttrium Aluminum Perovskite (Yb:YAP crystal) is a biaxial orthorhombic crystal, exhibiting high anisotropic thermal expansion coefficients and birefringence. Unlike Yb:YAG, Yb:YAP provide superior absorption cross-sections, which are highly dependent on their crystallographic orientation. This material is renowned for its excellent thermal conductivity and high optical efficiency, making it suitable for high-power laser applications. Yb:YAP are polarized, with emission and absorption cross-sections optimized based on crystal orientation. These properties make them an excellent choice for femtosecond and mode-locked thin-disk laser systems。

Yb:YAP crystals are utilized in a wide range of laser applications:

| Property | Value |

|---|---|

| Absorption Peak Wavelength | 978 nm |

| Absorption Cross-Section | 6.6 x 10^-20 cm^2 |

| Absorption Bandwidth | 4 nm |

| Laser Wavelength | 1040 nm |

| Lifetime of Yb Energy Level | 500 µs |

| Emission Cross-Section | 0.5 x 10^-20 cm^2 |

| Refractive Index (at 632.8 nm) | n_o = 1.7015, n_e = 1.7757 |

| Density | 5.35 g/cm^3 |

| Mohs Hardness | 8.5 |

| Thermal Conductivity | 11.7 W/m·K |

| dn/dT | 7.7 x 10^-6 K^-1 (n_o), 4.8 x 10^-6 K^-1 (n_e) |

| Thermal Expansion Coefficient | 2 x 10^-6 K^-1 |

| Typical Doping Level | 2-4% |

| Parameter | Value |

|---|---|

| Absorption Peak Wavelength | 978 nm |

| Emission Wavelength | 1040 nm |

| Emission Cross-Section | 0.5 x 10^-20 cm^2 |

| Refractive Index | n_o = 1.7015, n_e = 1.7757 |

| Thermal Conductivity | 11.7 W/m·K |

| Lifetime | 500 µs |

| Specification | Value |

|---|---|

| Orientation | c-cut, a-cut available |

| Clear Aperture | >90% |

| Face Dimension Tolerance | ±0.01 mm |

| Length Tolerance | ±0.1 mm |

| Parallelism Error | <20 arcsec |

| Perpendicularity Error | <10 arcmin |

| Surface Flatness | λ/10 @ 632.8 nm |

| Surface Quality | 20-10 Scratch/Dig |

| Protective Chamfers | <0.1 mm at 45° |

| Laser-Induced Damage Threshold (LIDT) | >10 J/cm^2 @1040 nm, 10 ns |

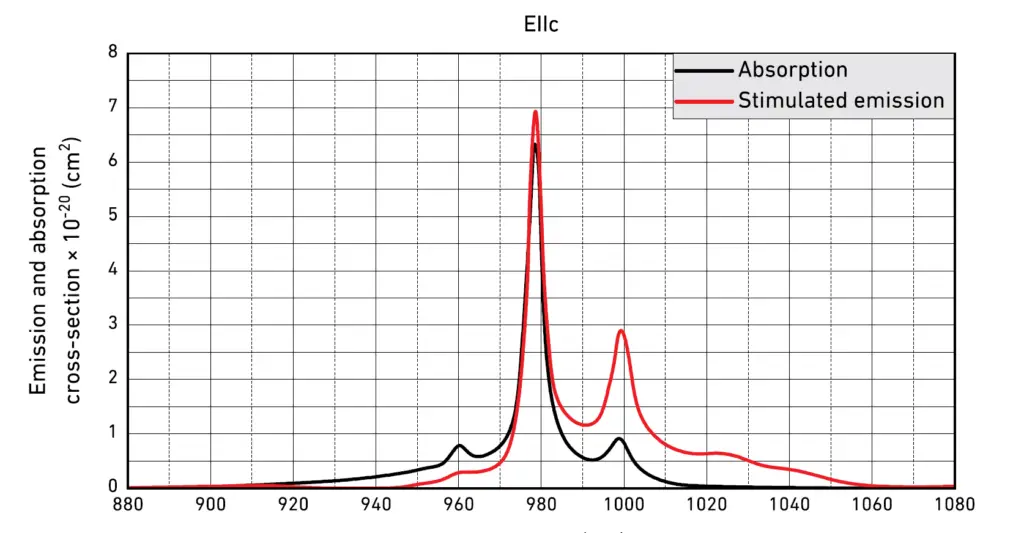

The Yb:YAP crystal has a high absorption coefficient at 978 nm and emission at 1040 nm, as shown in the graph. This supports efficient pump absorption and high laser output.

| Face Dimensions | Length | End Faces | Orientation | Doping | Coatings | SKU | Price (USD) |

|---|---|---|---|---|---|---|---|

| 3 x 3 mm | 2 mm | Right-angle cut | c-cut | 10% | AR@AR@960-1060 nm | 12826 | Request |

| 3 x 3 mm | 2 mm | Brewster-angle cut | c-cut | 10% | Uncoated | 12827 | Request |

| 3 x 3 mm | 2 mm | Right-angle cut | θ = 31°, φ = 0° | 10% | AR@AR@960-1060 nm | 12828 | Request |

| Customization | Upon Request | Available | Available | Custom | Available | — | Custom Quote |