Yb:YLF (Ytterbium-doped Lithium Yttrium Fluoride) crystals are advanced laser materials optimized for high-performance applications. Yb:YLF exhibits excellent thermal and mechanical properties, with a wide emission spectrum and broad absorption range centered around 960 nm, perfectly matching InGaAs laser diodes. Its low quantum defect ensures reduced thermal load during operation, making it an ideal choice for continuous-wave (CW) and mode-locked thin-disk laser applications. Yb:YLF’s simple electronic structure minimizes excited-state absorption and other detrimental quenching effects, offering high efficiency and reliability. This crystal’s low refractive index also eliminates the need for additional anti-reflective coatings in many applications.

Yb:YLF crystals are widely used in:

Example: Yb:YLF Crystal has been extensively utilized in femtosecond laser systems, offering pulse durations of <100 fs, making it indispensable in ultrafast applications.

| Property | Value |

|---|---|

| Chemical Formula | LiYF4:Yb |

| Dopant | Yb 5-20 at.% |

| Density | 3.95 g/cm³ |

| Thermal Conductivity | 6 W/mK |

| Mohs Hardness | 5 |

| Refractive Index | n = 1.448 |

| Melting Point | 819°C |

| Emission Peak | 1033 nm |

| Absorption Peak | 960 nm |

| Thermal Expansion Coefficient | 8-13 x 10^-6/K |

| Laser Wavelength | 1017 nm |

| Lifetime of Yb³⁺ Energy Level | 2.1 ms |

| Emission Cross-Section | 4.1 x 10^-20 cm² |

| Optical Property | Value |

|---|---|

| Absorption Peak Wavelength | 960 nm |

| Absorption Cross-Section | 10.5 x 10^-20 cm² |

| Absorption Bandwidth at Peak | 10 nm |

| Emission Peak Wavelength | 1033 nm |

| Emission Cross-Section | 4.1 x 10^-20 cm² |

| Lifetime of Yb³⁺ Energy Level | 2.1 ms |

| Parameter | Specification |

|---|---|

| Orientation | Z-cut, Brewster cut |

| Parallelism Error | <20 arcsec |

| Perpendicularity Error | <10 arcmin |

| Surface Quality | 20-10 (Scratch/Dig) |

| Surface Flatness | λ/10 @ 632.8 nm |

| Face Dimensions Tolerance | ±0.1 mm |

| Protective Chamfers | <0.1 mm at 45° |

| Laser-Induced Damage Threshold | >10 J/cm² @ 1030 nm, 10 ns |

| Mount | Unmounted |

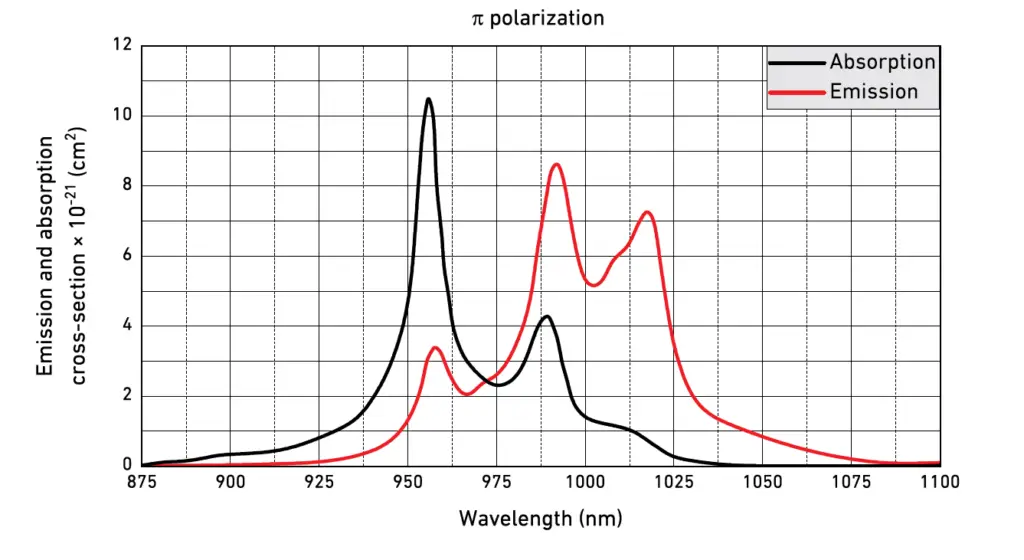

The emission and absorption spectra are with absorption peaking at 960 nm and emission centered around 1033 nm, supporting a wide tuning range. This facilitates efficient diode-pumping and mode-locked operation.

Anti-Reflective (AR) Coating

Wavelength Range: 960 nm, 1030–1060 nm

Reflectance: <0.2%

Broadband AR Coating

Wavelength Range: 940–1060 nm

Reflectance: <0.2%

| Face Dimensions | Length | End Faces | Doping | Coatings | Price (USD) |

|---|---|---|---|---|---|

| 3 x 3 mm | 8 mm | Right-Angle Cut | 5% | AR/AR @ 960-1060 nm | 590 |

| 3 x 3 mm | 8 mm | Brewster-Angle Cut | 5% | Uncoated | 540 |

| e8 mm | 8 mm | Right-Angle Cut | 5% | AR/AR @ 960-1060 nm | 680 |

| 3 x 3 mm | 4 mm | Brewster-Angle Cut | 10% | Uncoated | 540 |

| 3 x 3 mm | 2 mm | Right-Angle Cut | 10% | AR/AR @ 960-1060 nm | 590 |