Yb:YVO4 crystals, doped with ytterbium ions, are widely recognized for their superior optical and thermal properties, making them ideal for laser applications requiring high efficiency and power stability. These crystals offer a broad emission spectrum and a low quantum defect, significantly reducing thermal effects during operation. The simple electronic structure of Yb:YVO4 Crystal eliminates excited-state absorption and quenching processes, ensuring consistent performance. Due to their excellent thermal conductivity, these crystals are suitable for use in high-power thin-disk lasers, providing robust solutions for industrial and scientific applications. Additionally, their stable mechanical properties allow for precision fabrication and integration into complex optical systems.

Yb:YVO4 crystals are used across a range of laser-based applications, including:

| Property | Value |

|---|---|

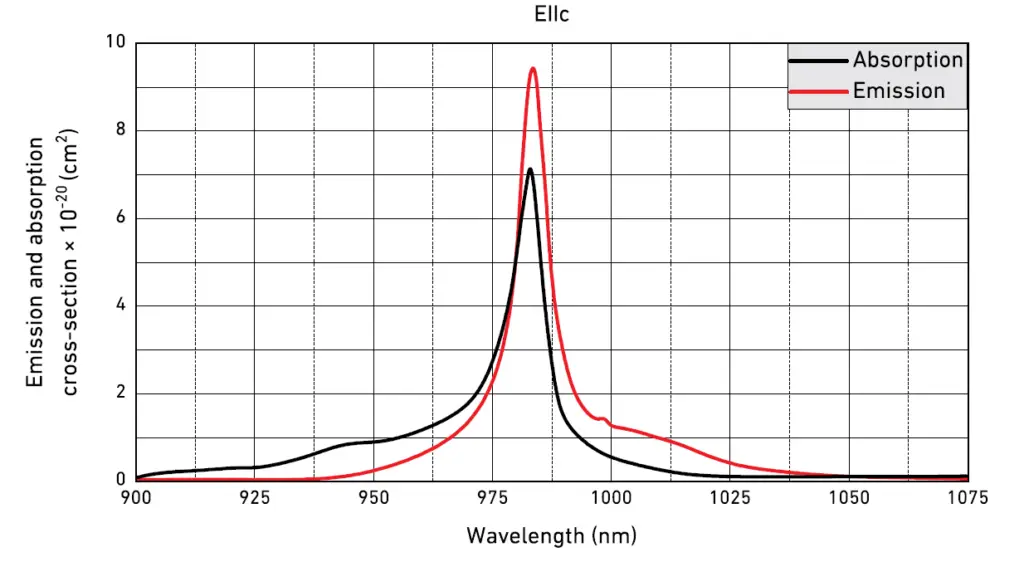

| Absorption peak wavelength | 985 nm |

| Absorption cross-section | 7.5 * 10^-20 cm² |

| Absorption bandwidth | 5 nm |

| Laser wavelength | 1027 nm |

| Lifetime of Yb³⁺ energy level | 250 µs |

| Emission cross-section | 10.5 * 10^-20 cm² |

| Refractive index @ 1064 nm | nₐ = 1.993, nₑ = 2.01 |

| Density | 4.22 g/cm³ |

| Mohs hardness | 5 |

| Thermal conductivity | ~5 W/m·K |

| dn/dT | 8.41 * 10^-6 K⁻¹ |

| Thermal expansion coefficient | 1.5 * 10^-6 K⁻¹ (a), 8.2 * 10^-6 K⁻¹ (c) |

| Typical doping level | 1–3 at.% |

| Parameter | Value |

|---|---|

| Emission spectrum range | ~960–1020 nm |

| Quantum defect | Low |

| Birefringence | Moderate |

| Optical transparency range | 400–5000 nm |

| Optical damage threshold | >10 J/cm² |

| Parameter | Specification |

|---|---|

| Dimensions tolerance | ±0.01 mm |

| Parallelism error | <20 arcsec |

| Perpendicularity error | <10 arcmin |

| Surface flatness | λ/10 @ 632.8 nm |

| Surface quality | 20-10 S-D |

| Protective chamfers | <0.1 mm at 45° |

| Clear aperture | >90% |

The spectrum demonstrates strong absorption and emission peaks centered around 985 nm and 1027 nm, respectively. These features make Yb:YVO4 suitable for applications requiring high beam quality and stability.

| Face Dimensions | Length | End Faces | Doping | Coatings | Price (USD) |

|---|---|---|---|---|---|

| 3 × 3 mm | 8 mm | Right-angle | 5% | AR@960–1060 nm | 640 |

| 3 × 3 mm | 4 mm | Brewster-angle | 5% | Uncoated | 540 |

| 8 × 8 mm | 8 mm | Right-angle | 10% | AR@960–1060 nm | 680 |

| Custom Sizes | Custom | Custom | Up to 20% | Coating options available | Contact us |