Er:YLF crystals are a highly efficient gain medium for laser systems due to their low phonon frequency, which enhances luminescence quantum efficiency by minimizing non-radiative relaxations. These crystals exhibit a long laser-emitting level lifetime, making them suitable for high-energy storage in Q-switched laser systems. Furthermore, their broad transparency range, extending from the vacuum ultraviolet (VUV) to the mid-infrared region (~10 µm), enables diverse optical applications. The negative thermo-optic coefficient of Er:YLF crystals provides a critical advantage in thermal management by reducing thermal-lensing effects, thus ensuring beam stability even under high-pump-power conditions.

Er:YLF crystals find applications across various domains due to their versatile optical and thermal properties:

| Property | Value |

|---|---|

| Orientation | a-cut |

| Clear Aperture | >90% |

| Face Dimensions Tolerance | ±0.01 mm |

| Length Tolerance | ±0.1 mm |

| Parallelism Error | <20 arcsec |

| Perpendicularity Error | <10 arcmin |

| Protective Chamfers | <0.1 mm at 45° |

| Surface Quality | 20–10 S-D |

| Surface Flatness | λ/10 @ 632.8 nm |

| Density | 3.95 g/cm³ |

| Mohs Hardness | 5 |

| Thermal Conductivity | 5 W·m⁻¹·K⁻¹ |

| dn/dT | -2 × 10⁻⁶ K⁻¹ |

| Thermal Expansion Coefficient | 8 × 10⁻⁶ K⁻¹ |

| Refractive Index (@2070 nm) | nₐ = 1.442; nₑ = 1.446 |

| Typical Doping Level | 15 at.% |

| Property | Value |

|---|---|

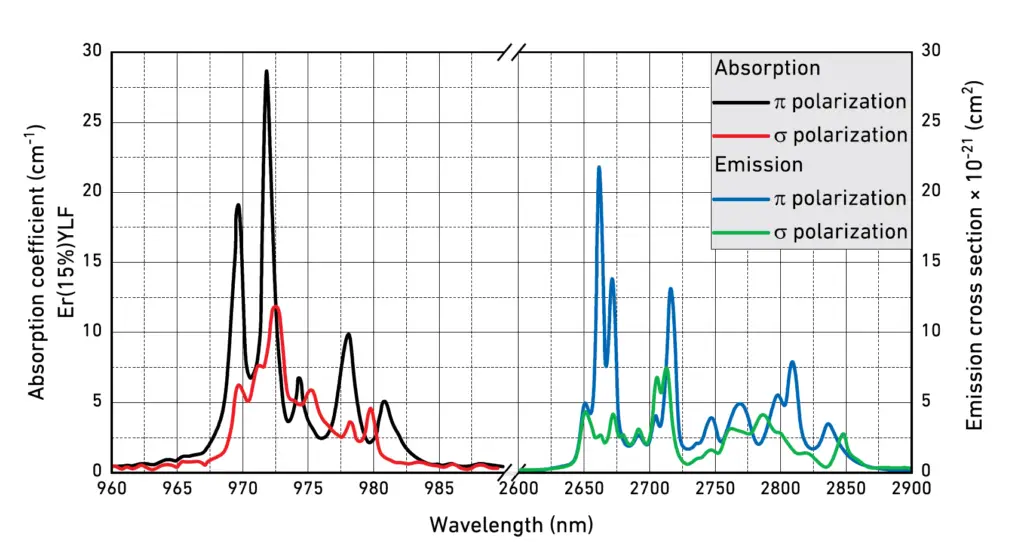

| Absorption Peak Wavelength | 972 nm |

| Absorption Cross-Section | 28 × 10⁻²⁰ cm² |

| Absorption Bandwidth | ~1 nm |

| Laser Wavelength | 2810 nm |

| Lifetime of Er³⁺ Energy Level | 4 ms |

| Emission Cross-Section (@2800 nm) | 1.5 × 10⁻²⁰ cm² |

| Crystal Structure | Tetragonal |

| Specification | Value |

|---|---|

| Face Dimensions Tolerance | ±0.01 mm |

| Length Tolerance | ±0.1 mm |

| Surface Flatness | λ/10 @ 632.8 nm |

| Parallelism Error | <20 arcsec |

| Perpendicularity Error | <10 arcmin |

| Clear Aperture | >90% |

| Protective Chamfers | <0.1 mm at 45° |

| Surface Quality | 20–10 S-D |

The transmission spectrum demonstrates excellent transparency across a wide range from VUV to ~10 µm, facilitating various optical and laser applications. Specific transmission curves can be provided upon request based on user requirements.

| Face Dimensions | Length | End Faces | Coatings | Price (USD) |

|---|---|---|---|---|

| 3 × 3 mm | 8 mm | Right-angle cut | Uncoated | $540 |

| 3 × 3 mm | 8 mm | Brewster-angle cut | AR (custom request) | $540 |

| 8 mm × 8 mm | 2 mm | Right-angle cut | AR (custom request) | $680 |