Tm:KYW (Thulium-doped Potassium Yttrium Tungstate) crystals are high-performance solid-state laser materials designed for CW and Q-switched laser applications emitting near the 2 µm wavelength range. The double tungstate structure of Tm:KYW makes it optically biaxial, with a wide fluorescence band and large emission cross-section. These properties are especially valuable in generating femtosecond pulses in solid-state laser systems. Tm:KYW also demonstrates superior thermal stability, making it suitable for high-power operations while ensuring minimal thermal lensing effects.

Tm:KYW crystals find application across a diverse range of fields due to their unique laser output capabilities and stable performance. Specific use cases include:

| Property | Value |

|---|---|

| Chemical Formula | Tm:KY(WO₄)₂ |

| Doping Concentration | ~5 at.% (typical) |

| Density | 6.5 g/cm³ |

| Mohs Hardness | 4.5 |

| Melting Point | ~1300°C |

| Crystal Structure | Monoclinic |

| Refractive Index (1040 nm) | 2.015 (Np), 2.021 (Nm), 1.997 (Ng) |

| Thermal Conductivity | 3.5 W/m·K |

| Thermal Expansion Coefficient | αx = 13 x 10⁻⁶, αy = 10 x 10⁻⁶, αz = 15 x 10⁻⁶ K⁻¹ |

| Optical Property | Value |

|---|---|

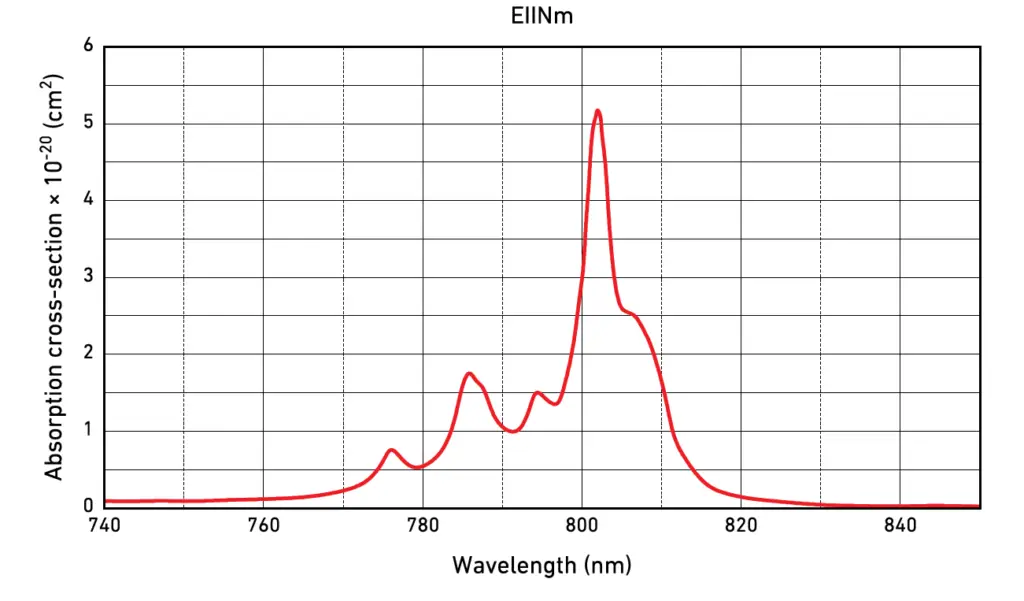

| Absorption Peak Wavelength | 802 nm |

| Absorption Bandwidth | ~5.5 nm |

| Absorption Cross-Section | 5.2 × 10⁻²⁰ cm² |

| Emission Wavelength | 1910 nm |

| Emission Cross-Section | 1.15 × 10⁻²⁰ cm² |

| Fluorescence Lifetime | 17 µs |

| Typical Doping Level | ~5 at.% |

| Parameter | Specification |

|---|---|

| Orientation | Np-cut |

| Clear Aperture | >90% |

| Face Dimensions Tolerance | ±0.1 mm |

| Length Tolerance | ±0.1 mm |

| Parallelism Error | <20 arcsec |

| Perpendicularity Error | <10 arcmin |

| Surface Quality | 20-10 S-D |

| Surface Flatness | λ/10 @ 632.8 nm |

| Protective Chamfers | <0.1 mm × 45° |

| Laser Induced Damage Threshold (LIDT) | >10 J/cm² @ 1900 nm, 10 ns |

| Mount | Unmounted |

Tm:KYW crystals exhibit broad absorption and emission bands peaking at 802 nm (absorption) and 1910 nm (emission). The wide spectral bandwidth supports their efficient lasing performance, especially for femtosecond pulse generation. The absorption curve demonstrates strong peaks in alignment with diode-pumping wavelengths, ensuring optimal energy transfer efficiency.

| Face Dimensions | Length | End Faces | Doping | Coatings | Price (USD) |

|---|---|---|---|---|---|

| 3 x 3 mm | 2 mm | Brewster-angle cut | 5% | Uncoated | Request |

| 3 x 3 mm | 2 mm | Right-angle cut | 5% | AR@802 nm + 1900-2000 nm | Request |

| Customizable | Custom | Custom | Custom | Custom coating options available | Request |