Terbium Gallium Garnet (TGG Crystal) is a high-performance magneto-optical crystal widely used in Faraday devices, including optical isolators and rotators. This cubic crystal system offers a unique combination of high thermal conductivity, low optical loss, and excellent Verdet constant, making it the material of choice for optical systems requiring high power and precision. TGG crystals are especially suitable for multi-stage laser amplification systems and ring-type laser cavities due to their robustness and optical clarity. With its high laser damage threshold, TGG ensures stable performance in demanding applications, including industrial and scientific laser systems.

| Property | Value |

|---|---|

| Chemical Formula | Tb3Ga5O12 |

| Crystal Structure | Cubic |

| Lattice Constant | 12.355 Å |

| Density | 7.13 g/cm³ |

| Melting Point | 1725°C |

| Mohs Hardness | 8.0 |

| Thermal Conductivity | 7.4 W m^-1 K^-1 |

| Laser Damage Threshold | >1 GW/cm² |

| Refractive Index @1064 nm | 1.954 |

| Property | Value |

|---|---|

| Verdet Constant | 35 Rad T^-1 m^-1 |

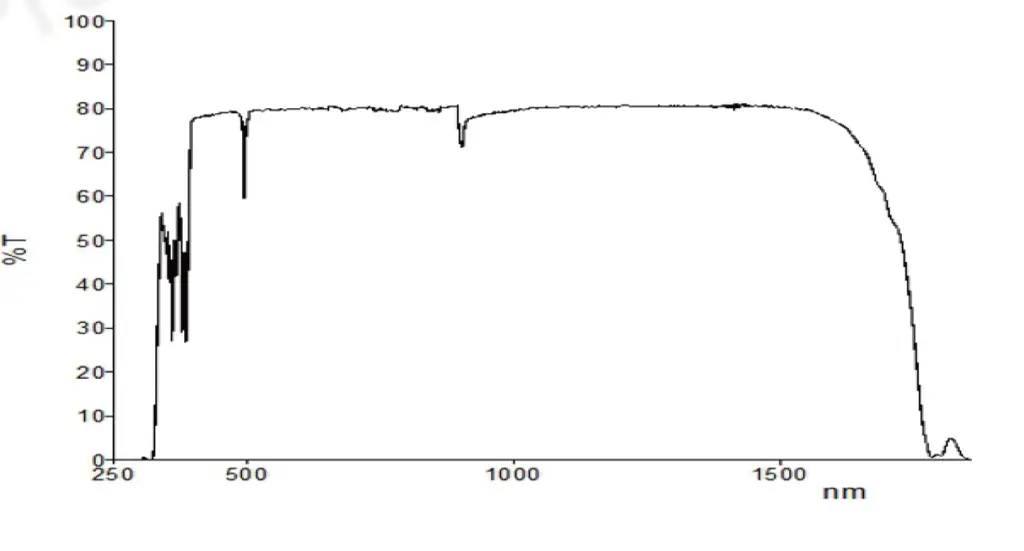

| Wavelength Range | 400 nm–1100 nm |

| Transmission Loss | <0.1%/cm |

| Absorption Bandwidth | Broad |

| Thermal Expansion Coefficient | 7.4 × 10^-6 K^-1 |

| Specification | Value |

|---|---|

| Orientation | [111] within ±15′ |

| Extinction Ratio | >30 dB |

| Diameter Tolerance | ±0.1 mm |

| Length Tolerance | ±0.2 mm |

| Surface Quality (Scratch/Dig) | 10/5 (MIL-PRF-13830B) |

| Flatness | ≤λ/8 @ 633 nm |

| Wavefront Distortion | ≤λ/8 @ 633 nm |

| Parallelism | 20 arc sec |

| Perpendicularity | 15 arc min |

| Chamfer | 0.2 mm × 45° |

| AR Coating | <0.2% @ 1064 nm |

| Face Dimensions (mm) | Length (mm) | Coatings | Price (USD) |

|---|---|---|---|

| 3 × 3 | 5 | Uncoated | 370 |

| 3 × 3 | 5 | AR@1064 nm | 435 |

| Custom Size | Custom | Coating as required | Request |