Terbium Scandium Aluminum Garnet (TSAG) is an advanced magneto-optical crystal designed for next-generation fiber lasers and other optical devices. With a high Verdet constant and low absorption rate, TSAG excels in visible and infrared wavelength applications. These characteristics enable TSAG to support high power operations while minimizing optical losses and thermally-induced birefringence. TSAG Crystal is well-suited for compact magneto-optical devices like isolators and Faraday rotators, where space and thermal considerations are critical. TSAG Crystal also exhibits robust thermal and mechanical stability, making it an ideal choice for high-power applications across the spectral range of 400–1600 nm.

TSAG crystals are widely used in:

| Property | Value |

|---|---|

| Chemical Formula | Tb3Sc2Al3O12 |

| Crystal Structure | Cubic, Space Group Ia3d |

| Lattice Parameter | a = 12.3 Å |

| Density | 5.91 g/cm³ |

| Melting Point | 1970°C ± 10°C |

| Mohs Hardness | 8.0 |

| Verdet Constant | 48 Rad·T^-1·m^-1 at 1064 nm |

| Absorption Loss | <0.1%/cm |

| Thermal Conductivity | 7.4 W·m^-1·K^-1 |

| Laser Damage Threshold | >1 GW/cm² |

| Refractive Index | 1.95 at 1064 nm |

| Property | Value |

|---|---|

| Transparency Range | 400–1600 nm |

| Verdet Constant | 48 Rad·T^-1·m^-1 at 1064 nm |

| Absorption Coefficient | <0.003 cm^-1 |

| Extinction Ratio | >30 dB |

| Birefringence | Negligible |

| Laser-Induced Damage Threshold | >1 GW/cm² |

| Specification | Value |

|---|---|

| Orientation | [111] within ±15′ |

| Extinction Ratio | >30 dB |

| Diameter Tolerance | ±0.1 mm |

| Length Tolerance | ±0.2 mm |

| Surface Quality (Scratch/Dig) | 10/5 to MIL-PRF-13830B |

| Flatness | <λ/8 @ 633 nm |

| Wavefront Distortion | <λ/8 @ 633 nm |

| Parallelism | 20 arc sec |

| Perpendicularity | <5 arc min |

| Chamfer | 0.2 mm × 45° |

Specification | Value |

Orientation | [111] within ±15′ |

Extinction Ratio | >30 dB |

Diameter Tolerance | ±0.1 mm |

Length Tolerance | ±0.2 mm |

Surface Quality (Scratch/Dig) | 10/5 to MIL-PRF-13830B |

Flatness | <λ/8 @ 633 nm |

Wavefront Distortion | <λ/8 @ 633 nm |

Parallelism | 20 arc sec |

Perpendicularity | <5 arc min |

Chamfer | 0.2 mm × 45° |

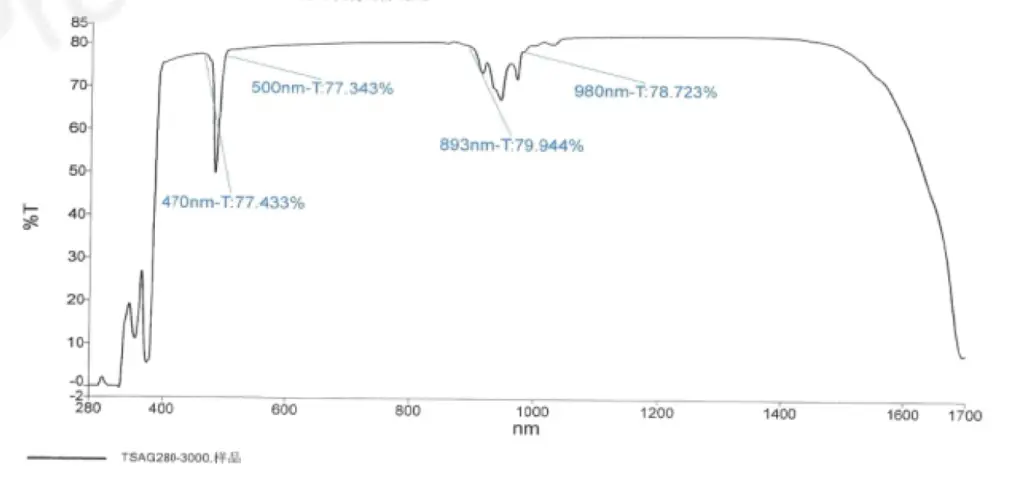

Transmission characteristics are optimized for wavelengths between 400 nm and 1600 nm, ensuring minimal loss and high transmission efficiency for Faraday rotation and isolation applications. A detailed curve can be obtained on request.

Custom coatings available upon request for specific wavelengths or spectral ranges

| Dimensions (mm) | Coating | Price (USD) |

|---|---|---|

| 3 × 3 × 5 | AR@1064 nm | 350 |

| 5 × 5 × 10 | AR@1064 nm | 600 |

| Custom Sizes | AR coatings upon request | Contact us |