Lithium Triborate (LBO) crystals are versatile nonlinear optical materials offering unparalleled transparency across the wavelength range of 160–2600 nm. Known for their high optical homogeneity and absence of photorefractive damage, LBO crystals are a leading choice in photonics for SHG, THG, and optical parametric oscillation (OPO). These crystals exhibit a high damage threshold, ensuring stability in high-intensity laser setups.

LBO’s orthorhombic crystal structure and non-critical phase-matching (NCPM) capabilities further enhance its suitability for applications requiring precise wavelength generation and harmonic conversion. Its broad acceptance angle and minimal walk-off make it particularly effective in maintaining beam quality. POC offers LBO crystals fabricated to stringent standards, ensuring reliability and customization options for various industries, including medical imaging, industrial processing, and defense.

| Property | Value |

|---|---|

| Crystal Structure | Orthorhombic, Pna21 |

| Lattice Parameters (Å) | a=8.4473, b=7.3788, c=5.1395 |

| Density (g/cm³) | 2.47 |

| Melting Point (°C) | ~834 |

| Mohs Hardness | 6 |

| Thermal Conductivity (W/m·K) | 3.5 |

| Thermal Expansion Coefficients | a=10.8×10⁻⁶, b=8.8×10⁻⁶, c=3.4×10⁻⁶ |

| Parameter | Type I SHG | Type II SHG |

|---|---|---|

| Transparency Range (nm) | 160–2600 | 160–2600 |

| SHG Phase Match Range (nm) | 551–2600 | 790–2150 |

| Effective NLO Coefficients (pm/V) | d11=0.05±0.009 | d11=0.05±0.006 |

| Walk-Off Angle (°) | 0.6 | 0.12 |

| Thermal-Optic Coefficient (K⁻¹) | dn/dt=3.9×10⁻⁶ | dn/dt=6.3×10⁻⁶ |

| Damage Threshold (GW/cm²) | >10 | >5 |

| Parameter | Specification |

|---|---|

| Dimension Tolerance | ±0.1 mm |

| Surface Flatness | λ/8 at 633 nm |

| Clear Aperture | >90% |

| Surface Quality | 10/5 Scratch/Dig |

| Parallelism | ≤20 arc seconds |

| Perpendicularity | ≤5 arc minutes |

| Damage Threshold | >10 GW/cm² at 1064 nm |

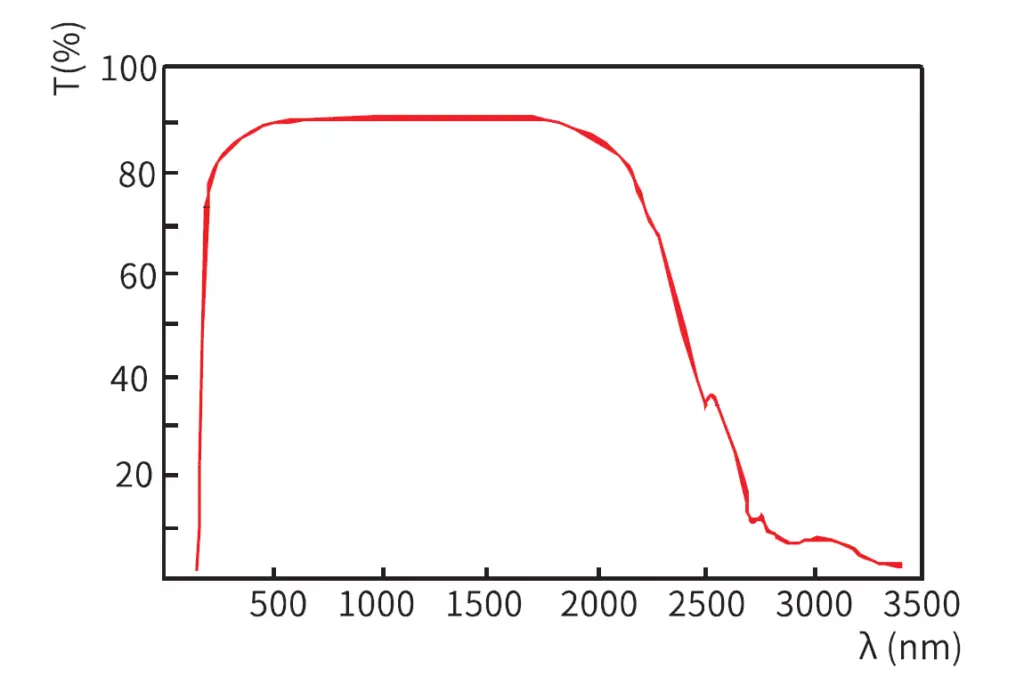

LBO crystals feature a transmission spectrum with excellent transparency from 160 nm to 2600 nm. The curve demonstrates >80% transmission efficiency across the operating range, ensuring optimal performance for nonlinear optical applications. (Include graphical representation)

| Dimension (mm) | Coating | Application | Price (USD) |

|---|---|---|---|

| 3×3×3 | AR@1064 nm | SHG Type I | 230 |

| 5×5×5 | AR@532 nm | THG Applications | 320 |

| 10×10×10 | Broadband AR Coating | OPO and OPA Systems | 470 |

| Custom Sizes | Upon Request | Tailored Solutions | Custom Quote |