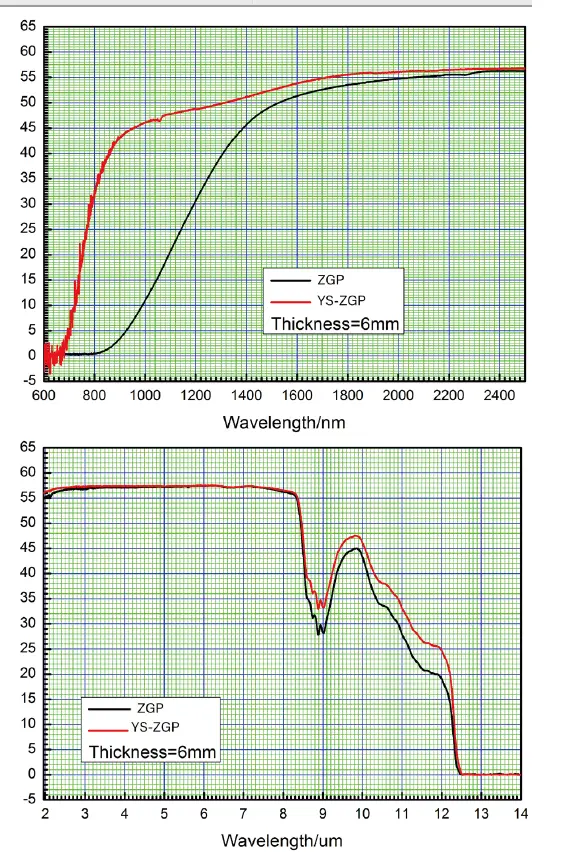

Zinc Germanium Phosphide (ZnGeP2) is a high-performance nonlinear optical crystal widely recognized for its exceptional properties in mid-infrared laser systems. It offers a broad transparency range from 0.74 μm to 12 μm, combined with a high nonlinear optical coefficient and excellent thermal conductivity, making it ideal for applications such as optical parametric oscillators (OPOs), difference frequency generation (DFG), and second harmonic generation (SHG).

ZnGeP2 crystals are particularly suited for high-power laser systems due to their low absorption coefficient and high laser-induced damage threshold. Their versatility extends to the generation of terahertz frequencies, remote sensing, and medical applications. At Photonics On Crystals (POC), we ensure high-quality fabrication and customization to meet specific application needs

| Property | Value |

|---|---|

| Chemical Formula | ZnGeP2 |

| Crystal Structure | Tetragonal |

| Lattice Parameters | a = 5.467 Å, c = 10.801 Å |

| Density | 4.13 g/cm³ |

| Melting Point | 1110 °C |

| Mohs Hardness | 5 |

| Thermal Conductivity | 35 W/m·K |

| Transparency Range | 0.74–12 μm |

| Property | Value |

|---|---|

| Transparency Range | 0.74–12 μm |

| Nonlinear Coefficient (d36) | 75 pm/V |

| Refractive Index at 10.6 μm | n = 3.067 |

| Absorption Coefficient | < 0.04 cm^-1 at 2.1 μm |

| Laser-Induced Damage Threshold | > 2 GW/cm² at 2.09 μm |

| Sellmeier Equation for Refractive Index | n² = A + (B * λ²) / (λ² – C) |

| Dispersion Equation Coefficients | A = 3.132, B = 1.297, C = 0.162 |

| Specification | Value |

|---|---|

| Dimension Tolerance (mm) | W ± 0.1 × H ± 0.1 × L ± 0.2 |

| Surface Flatness | λ/8 @ 633 nm |

| Surface Quality (Scratch/Dig) | 20/10 to MIL-PRF-13830B |

| Parallelism | < 30 arc sec |

| Perpendicularity | ≤ 15 arc min |

| Angle Tolerance (°) | Δθ ≤ 0.5 |

| Quality Warranty Period | One year under proper use |

Spectrum transmission curves for ZnGeP2 crystals are available upon request, showcasing excellent performance across the mid-IR spectrum.

| Product Code | Dimensions (mm) | Coating | Application |

|---|---|---|---|

| POC-ZnGeP2-12-10 | 10 × 10 × 10 | AR @ 0.74–12 μm | Mid-IR Laser Radiation Conversion |

| POC-ZnGeP2-Infrared | 12 × 12 × 12 | BBAR @ Mid-IR | Optical Parametric Oscillators |

| POC-ZnGeP2-Custom | Customizable | On Request | All Mid-IR Applications |