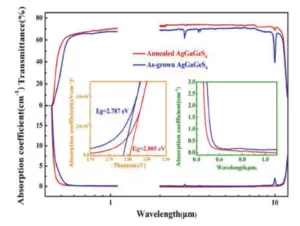

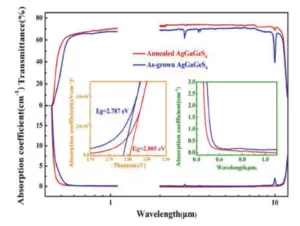

Spectrum transmission curves for AgGaGeS4 Crystal can be provided upon request, showcasing its transmission efficiency across the 0.5–11.5 µm range.

| Product Code | Dimensions (mm) | Coating Type | Application | Price (USD) |

|---|---|---|---|---|

| AGGS-1010-AR | 10 × 10 × 2 | AR Coating | Mid-IR Laser Systems | Request |

| AGGS-2020-AR | 20 × 20 × 5 | AR Coating | Spectroscopy Applications | Request |

| Custom | Custom Sizes | Customized | Tailored for Specific Needs | Request |

AgGaGeS4 Crystal is a cutting-edge mid-IR nonlinear optical crystal with excellent transmission properties, low absorption coefficients, and a high laser damage threshold. Its wide transparency range (0.5–11.5 µm) and nonlinear optical coefficients make it a superior alternative to traditional crystals in mid-IR laser systems. The material is particularly suitable for Nd:YAG laser-pumped systems and high-power mid-IR parametric oscillators. AgGaGeS4 crystals are available in annealed and as-grown forms, optimized for specific applications in infrared optics

| Property | Value |

|---|---|

| Chemical Formula | AgGaGeS4 |

| Crystal Structure | Orthorhombic |

| Lattice Parameters | a = 1.05 nm, b = 0.76 nm |

| Density | 4.5 g/cm³ |

| Mohs Hardness | 3 |

| Melting Point | 830 °C |

| Thermal Expansion Coefficients | αa = 7.8 × 10⁻⁶/K, αb = 8.1 × 10⁻⁶/K |

| Property | Value |

|---|---|

| Transparency Range | 0.5 – 11.5 µm |

| Absorption Coefficient | <0.05 cm⁻¹ at 1064 nm |

| Nonlinear Coefficient (d31) | 15 pm/V |

| Refractive Indices | no = 2.56, ne = 2.73 |

| Damage Threshold | >1.2 J/cm² at 1064 nm |

| Specification | Value |

|---|---|

| Dimension Tolerance (mm) | ±0.1 |

| Surface Flatness | λ/8 @ 633 nm |

| Surface Quality (Scratch/Dig) | 20/10 to MIL-PRF-13830B |

| Parallelism | <20 arc seconds |

| Perpendicularity | ≤15 arc minutes |

| Clear Aperture | ≥90% of the diameter |

| Coatings | AR coatings available |

| Laser Damage Threshold | >1.2 J/cm² at 1064 nm |

Spectrum transmission curves for AgGaGeS4 Crystal can be provided upon request, showcasing its transmission efficiency across the 0.5–11.5 µm range.

| Product Code | Dimensions (mm) | Coating Type | Application | Price (USD) |

|---|---|---|---|---|

| AGGS-1010-AR | 10 × 10 × 2 | AR Coating | Mid-IR Laser Systems | Request |

| AGGS-2020-AR | 20 × 20 × 5 | AR Coating | Spectroscopy Applications | Request |

| Custom | Custom Sizes | Customized | Tailored for Specific Needs | Request |