LGS Switch Crystal (Langasite, La₃Ga₅SiO₁₄) is a multifunctional crystal widely used in laser modulation and frequency conversion systems. With high electro-optic coefficients and a broad transmission range spanning ultraviolet to infrared (180 nm–8 µm), LGS crystals are a versatile solution for applications requiring fast laser pulse modulation and precise beam control.

LGS is highly favored for its robust thermal and mechanical stability, making it an excellent candidate for high-power laser systems, even under extreme environmental conditions. Additionally, it possesses a low acoustic velocity, minimizing acoustic losses and enabling high-performance Q-switching and electro-optic modulation. The high laser damage threshold (>1 GW/cm²) further ensures reliability in demanding applications like scientific research, medical laser systems, and industrial laser processing.

LGS Switch Crystals are designed for applications in high-energy and precision laser systems, including:

For instance, in industrial laser micromachining, LGS-based Q-switches enhance production speed and precision by enabling rapid pulse modulation, improving efficiency and reducing material waste.

| Property | Value |

|---|---|

| Chemical Formula | La₃Ga₅SiO₁₄ |

| Crystal Structure | Trigonal |

| Transmission Range | 180 nm–8 µm |

| Melting Point | ~1470°C |

| Density | 5.75 g/cm³ |

| Thermal Expansion Coefficient | 6.1 × 10⁻⁶/°C |

| Laser Damage Threshold | >1 GW/cm² @ 1064 nm |

| Acoustic Velocity | ~2800 m/s |

| Refractive Index | ~1.87 (at 1064 nm) |

| Optical Property | Value |

|---|---|

| Transparency Range | 180 nm–8 µm |

| Electro-Optic Coefficients | r11 = 2.3 pm/V, r41 = 1.8 pm/V |

| Refractive Index | 1.87 (at 1064 nm) |

| Dielectric Constant | ε = 18 (static dielectric constant) |

| Laser Damage Threshold | >1 GW/cm² @ 1064 nm |

| Acoustic Loss Coefficient | Low |

| Piezoelectric Coefficient | d11 = 6.8 × 10⁻¹² m/V |

| Parameter | Specification |

|---|---|

| Clear Aperture | 90% of central diameter |

| Surface Flatness | <λ/8 @ 632.8 nm |

| Surface Quality | 10-5 Scratch-Dig |

| Parallelism | <10 arc seconds |

| Perpendicularity | <5 arc minutes |

| Wavefront Distortion | <λ/8 @ 632.8 nm |

| Thickness Tolerance | ±0.1 mm |

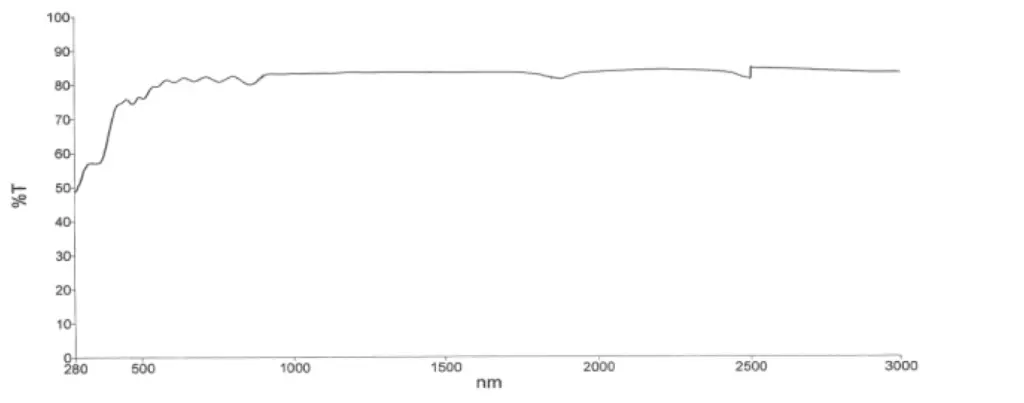

Transmission curve data is available upon request. Please contact POC for detailed spectral transmission performance or customized spectral data.

Standard coatings are available to enhance the optical performance of LGS Switch Crystals:

| Product Code | Dimensions (mm) | Coating Option | Price (USD) |

|---|---|---|---|

| LGS-001 | 10x10x5 | AR @ 1064 nm | $2500 |

| LGS-002 | 15x15x10 | Custom Coating | $3200 |

| LGS-Custom | Custom Dimensions | Application Specific | Contact Us |