V:YAG (Vanadium-doped Yttrium Aluminum Garnet) is a saturable absorber crystal specifically designed for passive Q-switching in lasers emitting between 1064 nm and 1440 nm. This advanced crystal exhibits superior ground-state absorption and negligible excited-state absorption, ensuring high efficiency in laser systems. V:YAG is grown using the Czochralski method, resulting in exceptional optical, mechanical, and thermal properties, making it highly versatile and reliable for demanding applications. The material’s robustness also provides UV resistance and exceptional laser damage thresholds, allowing for long-term use in various environments.

V:YAG Crystals are primarily used in passive Q-switching for lasers and provide significant advantages in laser systems such as:

V:YAG crystals are also commonly paired with active laser media like Nd:YAG, Nd:YVO4, and Er:Glass for enhanced Q-switching performance. The exceptional recovery time and emission cross-section values ensure high-efficiency pulse generation without the need for external modulators, simplifying laser design.

| Property | Value |

|---|---|

| Crystal Structure | Cubic |

| Density | 4.56 g/cm³ |

| Thermal Expansion Coefficient | 6.14 × 10^-6 K^-1 |

| Thermal Conductivity | 11.2 W/m·K |

| Mohs Hardness | 8.2 |

| Refractive Index | 1.82 @ 1064 nm |

| Property | Value |

|---|---|

| Laser Wavelength Range | 1064 nm – 1440 nm |

| Absorption Cross-Section | 72 × 10^-20 cm² @ 1340 nm |

| Excited-State Absorption Cross-Section | 7.4 × 10^-20 cm² |

| Recovery Time (T3) | 5 – 37 ns |

| Emission Cross-Section | Varies with laser media |

| Parameter | Value |

|---|---|

| Initial Transmission (T0) | 30-98% @ 1340 nm |

| Face Dimensions Tolerance | +0.0/-0.1 mm |

| Parallelism Error | <20 arcsec |

| Protective Chamfers | <0.1 mm at 45° |

| Surface Flatness | <λ/8 @ 632.8 nm |

| Laser Damage Threshold | >10 J/cm² @ 1340 nm |

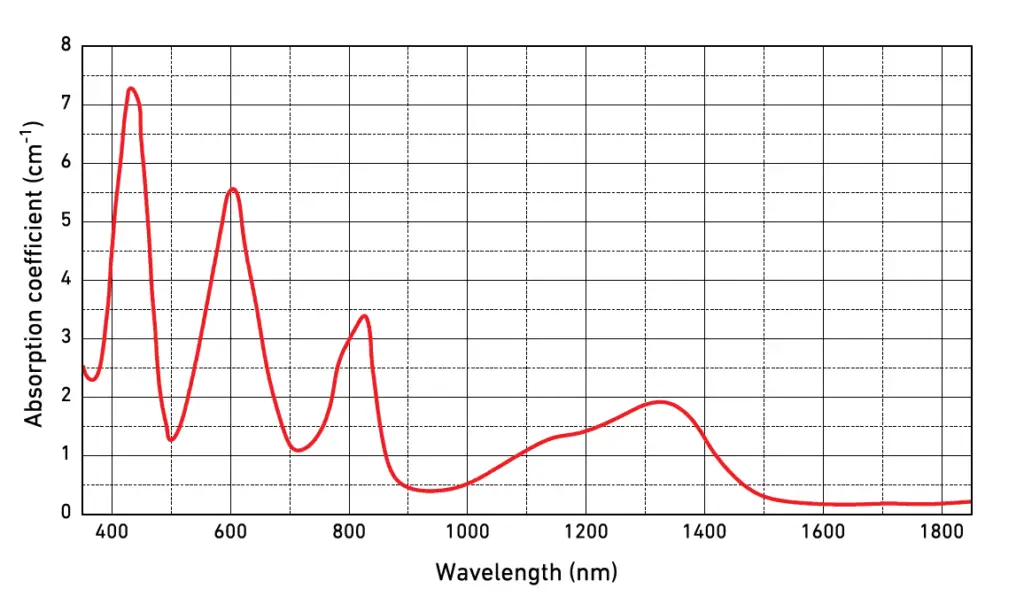

The absorption coefficient graph provided indicates V:YAG’s superior ground-state absorption in the spectral range from 1064 nm to 1440 nm, ensuring high performance in Q-switched laser systems.

Anti-Reflective Coatings: AR coatings are optimized for 1310-1360 nm on both crystal faces, ensuring low reflection losses and improved efficiency in laser systems.

| Face Dimensions (mm) | Initial Transmission | Coatings | Price (USD) |

|---|---|---|---|

| 6 × 6 | 30% @ 1340 nm | AR @ 1310-1360 nm | 540 |

| 6 × 6 | 40% @ 1340 nm | AR @ 1310-1360 nm | 540 |

| 3 × 3 | 70% @ 1340 nm | AR @ 1310-1360 nm | 540 |

| 3 × 3 | 95% @ 1340 nm | AR @ 1310-1360 nm | 540 |

| Customization Available | Upon Request | Optimized Coatings | Contact Us |