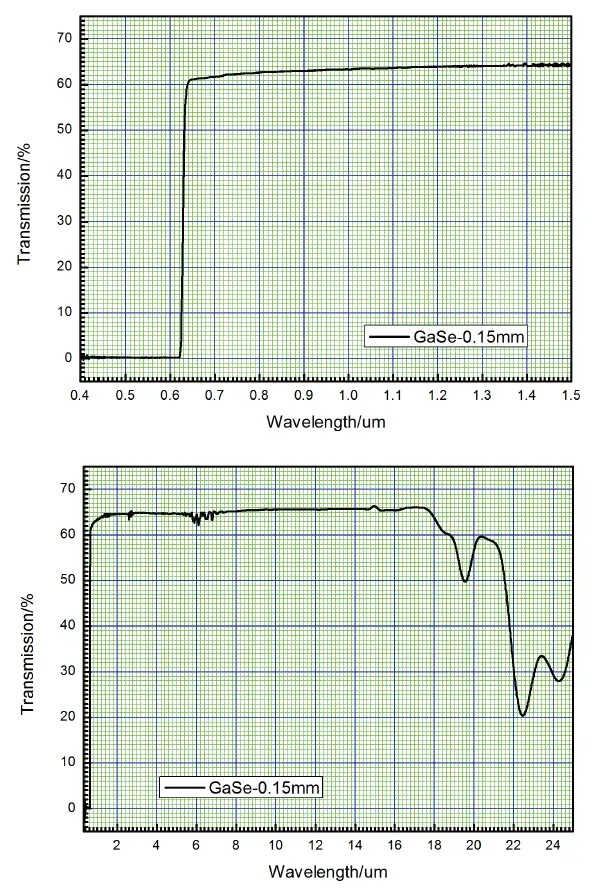

Gallium Selenide (GaSe) crystals are unique negative uniaxial semiconductor crystals with hexagonal symmetry, featuring a bandgap of 2.2 eV at 300 K. These crystals offer exceptional damage thresholds and large nonlinear coefficients, with a broad transparency range from 0.62 µm to 20 µm. GaSe crystals exhibit low absorption coefficients, making them highly suitable for mid-IR applications, terahertz wave generation, and detection systems. Their strong birefringence enhances their application versatility in high-frequency terahertz spectrometry and imaging systems. However, their fragile structure limits the feasibility of antireflection coatings.

GaSe crystals are widely used in advanced photonics applications:

| Property | Value |

|---|---|

| Chemical Formula | GaSe |

| Crystal Structure | Hexagonal, -62m symmetry |

| Lattice Parameters | a = 3.74 Å, c = 15.89 Å |

| Density | 5.03 g/cm³ |

| Mohs Hardness | Approx. 0 |

| Transparency Range | 0.62–20 µm |

| Nonlinear Coefficient (d22) | 54 pm/V |

| Refractive Indices (nₒ, nₑ) | nₒ > nₑ (varies with wavelength) |

| Sellmeier Equations | Specified for 5.3 µm and 10.6 µm |

| Damage Threshold | 28 MW/cm² (9.3 µm, 150 ns pulse) |

| Wavelength (µm) | nₒ | nₑ | Walk-Off Angle |

|---|---|---|---|

| 5.3 | 2.7233 | 2.3966 | 4.1° |

| 10.6 | 2.6975 | 2.3745 | – |

| Parameter | Value |

|---|---|

| Standard Sizes | ≥ Ø7 mm clear aperture |

| Surface Quality | Cleaved surface |

| Thickness Tolerance | ±0.2 mm |

| Mount Options | Ø25.4 mm anodized aluminum mount |

The spectral transmission curve of GaSe demonstrates minimal absorption across the 0.62 µm to 20 µm range, making it highly effective for mid-infrared applications.

| Clear Aperture | Length | Orientation | Coating | Price (USD) |

|---|---|---|---|---|

| ≥ Ø7 mm | 0.2 mm | Z-cut | Uncoated | $1,950 |

| ≥ Ø7 mm | 0.5 mm | Z-cut | Uncoated | $1,750 |

| ≥ Ø7 mm | 1.0 mm | Z-cut | Uncoated | $2,150 |

| ≥ Ø7 mm | 2.0 mm | Z-cut | Uncoated | $2,450 |