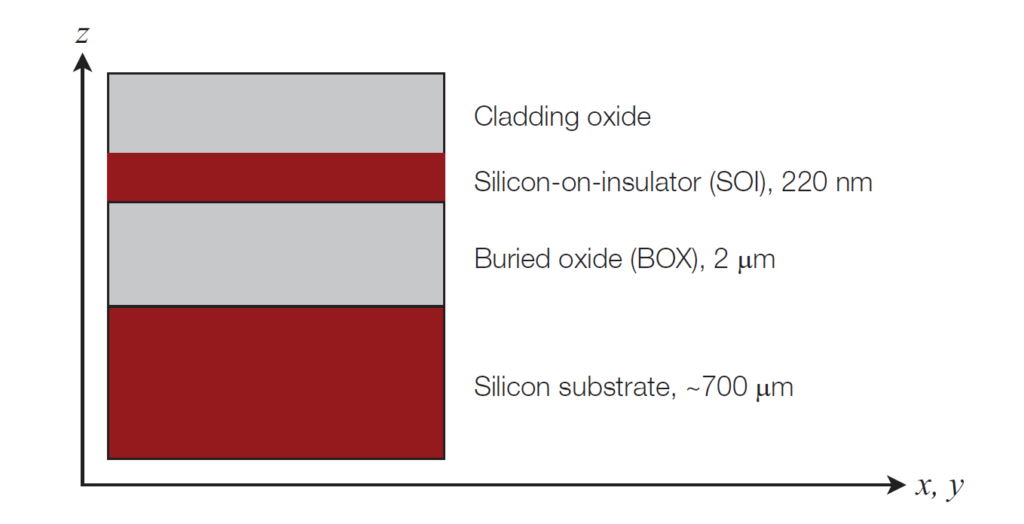

The Silicon-on-Insulator (SOI) is a widely used technology in silicon photonics, particularly in electronics for high-performance circuits. The typical SOI wafer consists of a 725 µm thick silicon substrate, 2 µm of buried oxide (BOX), and a 220 nm top layer of crystalline silicon. This top crystalline silicon layer plays a critical role as it defines the waveguides and optical devices.

The SOI wafer’s material properties are essential in designing optical and optoelectronic devices. For example, a 220 nm thickness has become a standard in multi-project wafer foundries and other services for fabricating silicon photonics. However, this is not the only thickness used, as applications may require different specifications based on design needs, and the thickness could vary slightly (±5 nm), which can impact performance.

Wavelength Dependence of Silicon

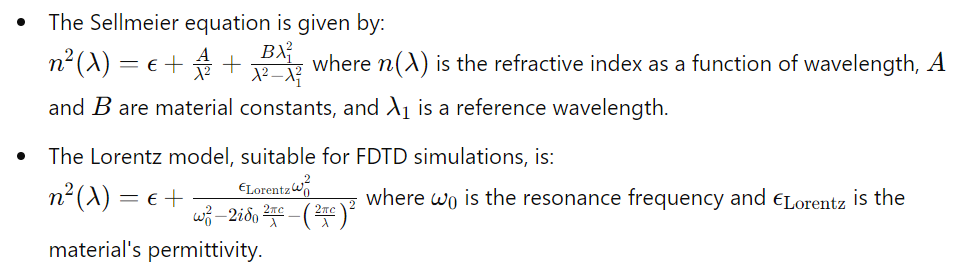

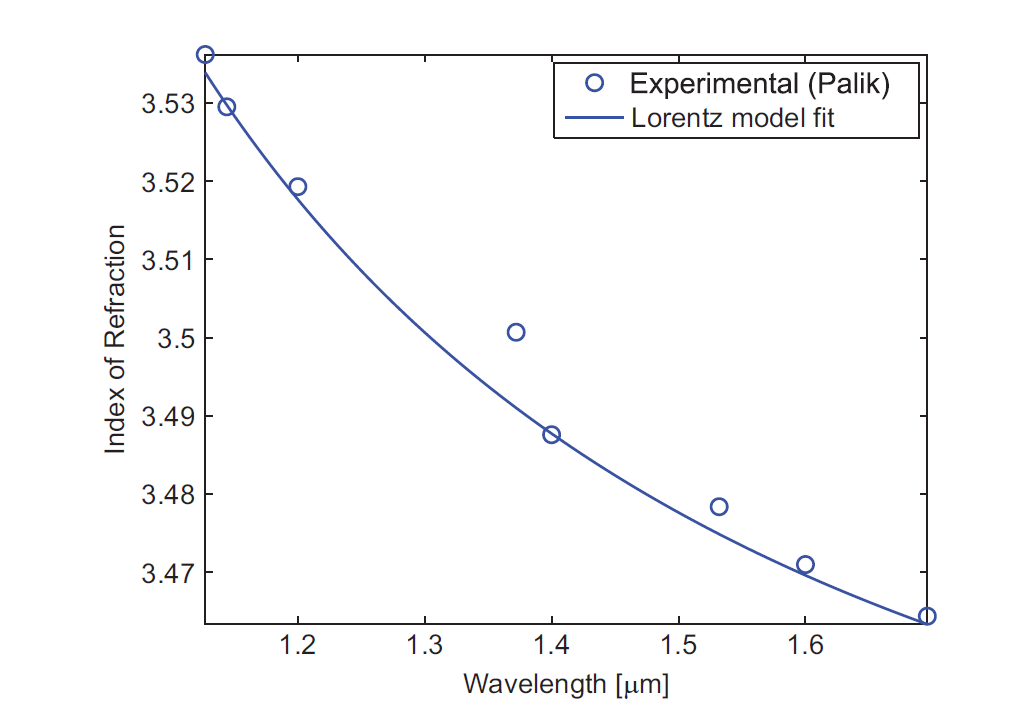

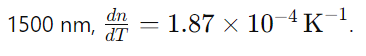

Silicon’s refractive index changes with wavelength. This variation must be considered when designing devices for different wavelength ranges. The Sellmeier equation is commonly used to describe the index of refraction for silicon. However, for more accurate modeling in simulations, a Lorentz model is employed. This model aligns well with FDTD (Finite Difference Time Domain) simulations to ensure consistent results.

Temperature Dependence of Silicon

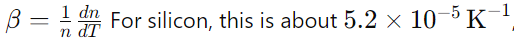

Silicon’s refractive index also changes with temperature due to the shifts in the distribution functions of carriers and phonons and the shrinkage of the bandgap with temperature. This is critical when designing thermally tunable devices like ring resonators. The refractive index temperature dependence can be approximated as:

The SOI platform offers significant advantages for designing advanced photonic and optoelectronic devices, with the ability to precisely control waveguides, index tuning, and thermal behavior, which are essential for efficient and scalable silicon photonic systems.