Neodymium Doped Yttrium Orthovanadate (Nd:YVO4) is a highly efficient laser host crystal widely used in diode-pumped solid-state lasers, particularly for low to medium power density applications. Its absorption and emission properties surpass those of Nd:YAG, making it a superior choice for compact and efficient laser systems.

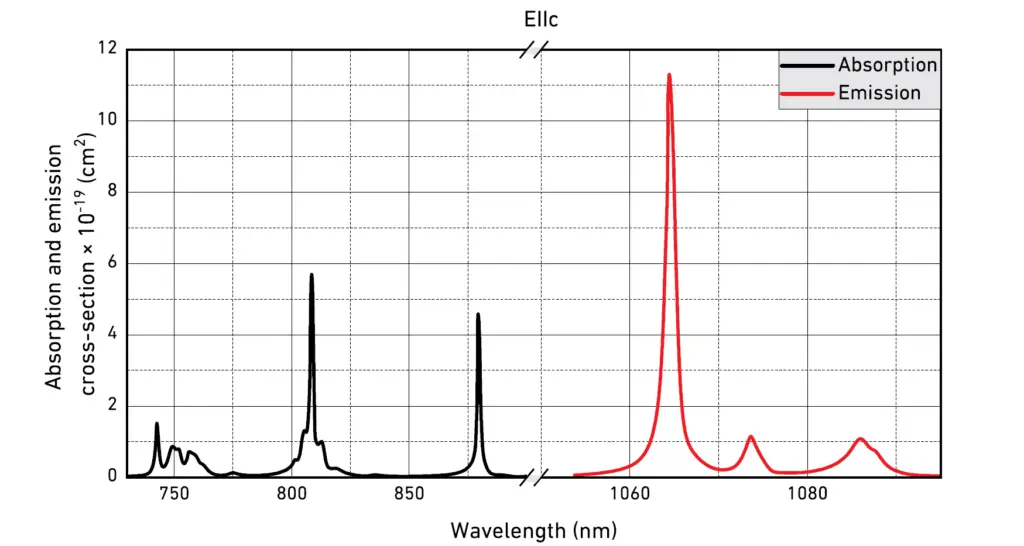

Nd:YVO4 features a wide absorption bandwidth (~808 nm), enabling efficient energy absorption even with non-ideal laser diode wavelengths. The crystal is also known for its large stimulated emission cross-section, which supports high-power output and superior performance in continuous-wave (CW) and pulsed laser systems. Additionally, the uniaxial birefringence of Nd:YVO4 ensures linearly polarized emission, enhancing efficiency for frequency-doubling processes when combined with nonlinear crystals like LBO or KTP.

Nd:YVO4-based lasers are extensively used in a variety of applications, including precision machining, medical diagnostics, spectroscopy, and laser displays. With its compact design and high quantum efficiency, Nd:YVO4 is rapidly replacing traditional lamp-pumped laser systems in modern applications.

Nd:YVO4 crystals are widely used in advanced laser systems due to their superior performance characteristics. Examples include:

| Property | Value |

|---|---|

| Chemical Formula | Nd:YVO4 |

| Crystal Structure | Zircon Tetragonal, Space Group D4h-14/amd |

| Lattice Constants | a = b = 7.12 Å, c = 6.29 Å |

| Density | 4.22 g/cm³ |

| Mohs Hardness | 4–5 (Glass-like) |

| Thermal Expansion | a = 4.43 × 10⁻⁶ /K at 300 K; c = 11.37 × 10⁻⁶ /K |

| Thermal Conductivity | a = 5.23 W/m·K; c = 5.10 W/m·K |

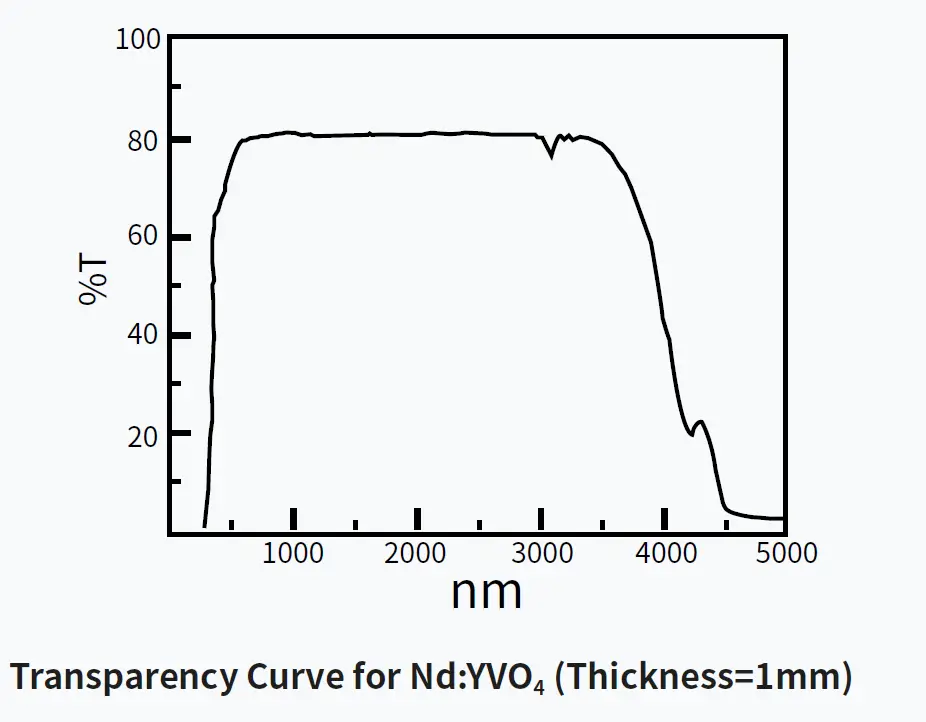

| Transparency Range | ~400 nm to 5 µm |

| Property | Value |

|---|---|

| Lasing Wavelengths | 1064 nm (IR), 1342 nm |

| Thermal Optical Coefficient | dn/dT = 8.5 × 10⁻⁶ /K (nₒ), dn/dT = 2.9 × 10⁻⁶ /K (nₑ) |

| Stimulated Emission Cross-Section | 25 × 10⁻¹⁹ cm² at 1064 nm |

| Fluorescent Lifetime | 90 µs (1% Nd doping) |

| Absorption Coefficient | 31.4 cm⁻¹ at 808 nm |

| Intrinsic Loss | 0.02 cm⁻¹ at 1064 nm |

| Gain Bandwidth | 0.96 nm at 1064 nm |

| Polarized Laser Emission | π-Polarization, parallel to optical c-axis |

| Diode Pumped Efficiency | >60% |

| Specification | Value |

|---|---|

| Dimension Tolerance | ±0.1 mm (standard); ±0.005 mm (high precision) |

| Clear Aperture | Central 95% of the diameter |

| Surface Quality | 20-10 Scratch-Dig |

| Surface Flatness | λ/8 at 633 nm |

| Parallelism | <10 arc seconds |

| Perpendicularity | <5 arc minutes |

| Chamfer | 0.1 mm at 45° |

| Damage Threshold | >15 J/cm² (10 ns, 10 Hz at 1064 nm) |

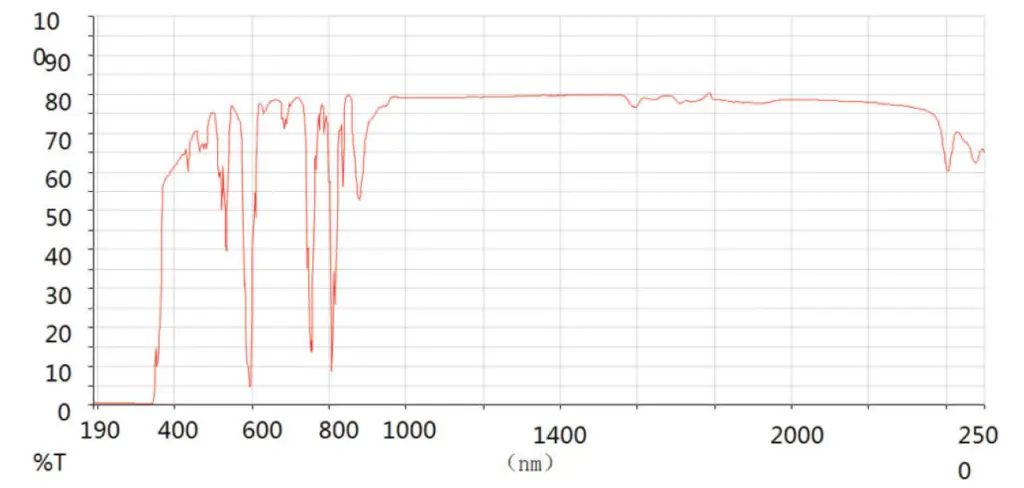

Nd:YVO4 crystals exhibit high transparency over a wide range, from visible to infrared wavelengths (400 nm to 5 µm). A typical absorption curve for 0.5% Nd:YVO4 indicates efficient energy absorption at 808 nm for diode pumping, with minimal absorption losses across other wavelengths.

(Graphical data available upon request.)

Adhesion Test: Compliant with MIL-C-675C military standards, an adhesion test involved applying a tape that meets LT-90 specifications onto the lens film layer. The tape was affixed fully and then removed vertically. This procedure was performed three times, resulting in no blistering or peeling.

Temperature Test: In line with MIL-C-675C specifications, test pieces were subjected to temperatures of -62±1℃ and 71±1℃. After maintaining them at room temperature (16℃~32℃) for two hours, the adhesion test was repeated, confirming no film detachment.

Abrasion Resistance Test: Conforming to MIL-C-675C and CCC-C-440 standards, the abrasion resistance test involved a gauze tester applying a minimum force of 1.0 lbs (0.45 kg) to the film. This was repeated 25 times with gauze widths of 1/4 inch (6.4mm) and 3/8 inch (9.5mm), ensuring no damage occurred to the film surface.

Humidity Test: Under MIL-C-675C criteria, the test piece was placed in a controlled temperature and humidity chamber set to 49 ±2℃ and 95%~100% humidity for 24 hours. The film remained intact, with no peeling, scratches, or other defects.

Solvent and Cleaning Testing: Following MIL-C-675C specifications, test pieces were exposed to room temperature conditions (16℃~32℃) and tested with acetone and alcohol for at least 10 minutes each. After air drying and subsequent cleaning with a cotton cloth soaked in alcohol, the film surface showed no signs of peeling or scratches.

Salt Spray Test: After 100 hours in a 35°C environment with a 5% saltwater concentration, the film showed no signs of damage.

| Product Code | Dimensions (mm) | Doping Level (Nd) | Coating | Price (USD) |

|---|---|---|---|---|

| NDYVO4-01 | 3 × 3 × 0.5 | 1.0% | AR @ 808 nm / 1064 nm | Request Quote |

| NDYVO4-02 | 6 × 6 × 1 | 1.0% | Customizable | Request Quote |

| NDYVO4-03 | 10 × 10 × 2 | 0.5% | Customizable | Request Quote |

| Custom-NDYVO4 | Customizable | Customizable | Customizable | Request Quote |