Er,Yb:Phosphate Glass is a co-doped glass known for its excellent laser performance in the “eye-safe” spectral range of 1.5–1.6 µm. The material combines an extended erbium upper laser level lifetime (~8 ms) with a short lifetime (~2–3 ms) of the energy transfer stage between Yb and Er ions. This unique configuration allows efficient energy transfer, minimizing back-energy losses and improving overall system efficiency. Additionally, phosphate glass exhibits a low phonon energy, reducing non-radiative relaxations and enhancing luminescence quantum efficiency. Due to its superior optical and mechanical properties, Er,Yb:Phosphate Glass is widely used for creating compact, energy-efficient lasers operating in demanding applications.

| Property | Unit | Value |

|---|---|---|

| Absorption Peak Wavelength | nm | 970 |

| Absorption Cross-Section | cm² | 1.7 × 10⁻²⁰ |

| Absorption Bandwidth | nm | 20 |

| Laser Wavelength | nm | 1534 |

| Emission Cross-Section | cm² | 8 × 10⁻²⁰ |

| Density | g/cm³ | 2.93 |

| Mohs Hardness | – | 6 |

| Thermal Conductivity | W/m·K | 0.65 |

| dn/dT (Refractive Index Change) | K⁻¹ | -2.1 × 10⁻⁶ |

| Thermal Expansion Coefficient | K⁻¹ | 0.3–1.3 × 10⁻⁶ |

| Typical Doping Levels | – | 0.1–1.0% (Er), 1.7–4% (Yb) |

| Property | Value |

|---|---|

| Refractive Index at 1534 nm | 1.52 |

| Yb to Er Energy Transfer Efficiency | High |

| Emission Lifetime (4I11/2 level) | ~8 ms |

| Absorption Edge | ~970 nm |

| Property | Value |

|---|---|

| Clear Aperture | >90% |

| Face Dimensions Tolerance | ±0.01 mm |

| Length Tolerance | ±0.1 mm |

| Parallelism Error | <20 arcsec |

| Perpendicularity Error | <10 arcmin |

| Surface Quality | 20–10 S/D |

| Surface Flatness | λ/10 @ 632.8 nm |

| Mount | Unmounted |

Property | Value |

Clear Aperture | >90% |

Face Dimensions Tolerance | ±0.01 mm |

Length Tolerance | ±0.1 mm |

Parallelism Error | <20 arcsec |

Perpendicularity Error | <10 arcmin |

Surface Quality | 20–10 S/D |

Surface Flatness | λ/10 @ 632.8 nm |

Mount | Unmounted |

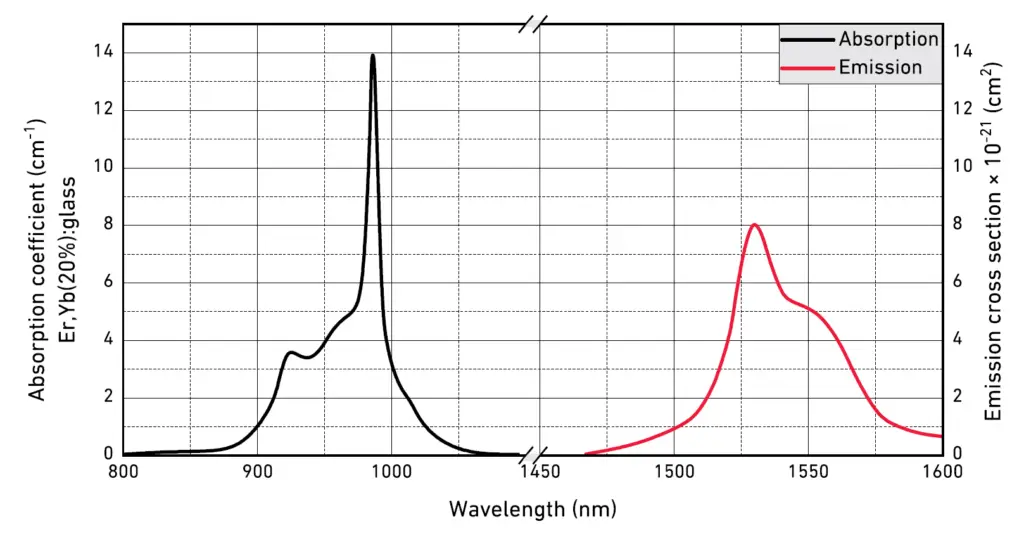

A comprehensive transmission spectrum (graph shown) reveals the high absorption at ~970 nm and a strong emission at ~1534 nm, with minimal losses and consistent transmission efficiency over a broad wavelength range.

Standard AR coatings available for dual wavelengths:

Customized coatings available upon request.

| Face Dimensions | Length | End Faces | Doping | Coatings | Price (USD) |

|---|---|---|---|---|---|

| 3 × 3 mm | 5 mm | Brewster-angle cut | Yb: 20%, Er: 1% | Uncoated | 370 |

| 3 × 3 mm | 10 mm | Right-angle cut | Yb: 20%, Er: 0.5% | AR@940 nm + 1535 nm | 435 |

| 3 × 3 mm | 10 mm | Right-angle cut | Yb: 20%, Er: 0.5% | AR@940 nm + 1535 nm | 435 |

| Customization | Any | Any | Any | Upon request | Upon Request |