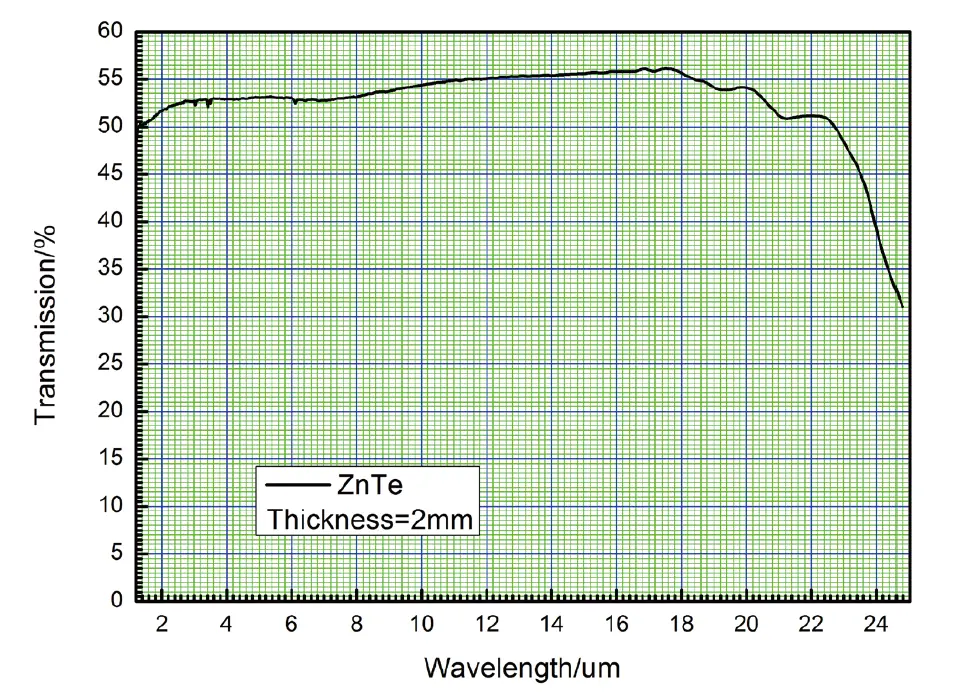

Zinc Telluride (ZnTe) is a direct-bandgap II-VI compound semiconductor material with a cubic zinc blende crystal structure. It is an ideal electro-optic crystal widely utilized in terahertz (THz) wave generation and detection due to its exceptional optical and electronic properties. With a wide range of applications, ZnTe crystals boast high transmission efficiency in the mid-infrared (7-12 μm) and visible spectrum.

The crystal’s intrinsic qualities include a high electro-optic coefficient, moderate birefringence, and excellent purity levels that contribute to its performance in high-power and ultrafast laser systems. Its compact lattice structure ensures low defect density, making it a reliable choice for industrial-grade THz imaging and spectroscopy applications. Furthermore, ZnTe’s ability to support ultra-thin and large-area production makes it a versatile option for demanding optical setups.

ZnTe crystals are extensively utilized in a variety of high-performance optical and electronic fields:

| Property | Value |

|---|---|

| Crystal Structure | Cubic Zinc Blende |

| Lattice Constant | a = 6.1034 nm |

| Density | 5.633 g/cm³ |

| Bandgap | 2.26 eV |

| Transparency Range | 7-12 μm |

| Transmission Efficiency | 60% (7-12 μm) |

| Refractive Index | n (λ=10.6 μm) = 2.7 |

| Electro-Optic Coefficient | y41 = 4.0 pm/V |

| Electrical Resistivity | Low: <10³ Ω·cm, High: >10⁹ Ω·cm |

| Wavelength (λ) | Refractive Index (n) | Transparency (%) | Electro-Optic Efficiency |

|---|---|---|---|

| 7 μm | 2.8 | 60% | High |

| 10.6 μm | 2.7 | 55% | High |

| 12 μm | 2.6 | 50% | Moderate |

| Specification | Parameter |

|---|---|

| Aperture Size | Up to 30 × 30 mm |

| Minimum Thickness | 0.01 mm |

| Crystal Orientation | [100] or [111] |

| Surface Flatness | <λ/10 |

| Surface Roughness | Ra < 0.01 nm |

ZnTe Crystals are typically delivered uncoated to preserve their surface integrity. Anti-reflective coatings are available upon request depending on application-specific requirements.

| Clear Aperture | Thickness | Orientation | Coating | Price (USD) | Customization Available |

|---|---|---|---|---|---|

| 30 × 30 mm | 0.5 mm | [100] | Uncoated | $2,500 | Yes |

| 20 × 20 mm | 1.0 mm | [111] | Uncoated | $2,000 | Yes |

| 15 × 15 mm | 2.0 mm | [100] | Uncoated | $1,500 | Yes |