| Property | Value |

|---|---|

| Crystal Structure | Cubic |

| Density | 3.58 g/cm³ |

| Thermal Expansion Coefficient | 6.14 × 10^-6 K^-1 |

| Thermal Conductivity | 17 W/m·K |

| Mohs Hardness | 8 |

| Refractive Index | 1.6 – 1.75 |

| Parameter | Value |

|---|---|

| Wavelength Range | 1.3 μm – 1.6 μm |

| Initial Transmission (T₀) | 50%-99% @ 1535 nm |

| Ground-State Absorption (σg) | 3.5 × 10^-19 cm² @ 1.54 μm |

| Excited-State Absorption (σe) | 0.1 × 10^-19 cm² @ 1.54 μm |

| Recovery Time (T₃) | 220–350 ns |

| Laser-Induced Damage Threshold | >8 J/cm² @ 1535 nm, 10 ns |

| Specification | Value |

|---|---|

| Dimensions (Face) | 3 × 3 mm, 5 × 5 mm |

| Clear Aperture | >90% |

| Surface Flatness | λ/4 @ 632.8 nm |

| Wavefront Distortion | λ/8 @ 632.8 nm |

| Parallelism | <20 arcseconds |

| Perpendicularity Error | <5 arcminutes |

| Surface Roughness | <0.1 nm @ 45° |

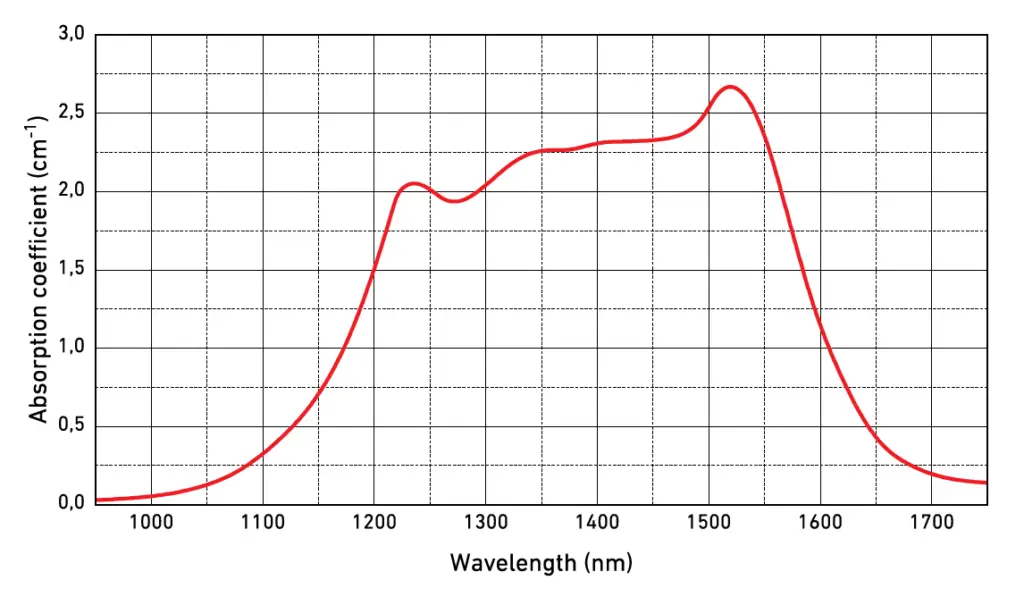

Spectral transmission curves for Co:Spinel Crystal indicate low absorption losses and high transmission efficiency in the 1.3 μm to 1.6 μm range. The data supports its use in high-performance laser systems requiring passive Q-switching.

| Face Dimensions | Initial Transmission | Coating | SKU | Price (USD) |

|---|---|---|---|---|

| 3 × 3 mm | 80% @ 1535 nm | AR/AR | 7331 | $370 |

| 5 × 5 mm | 97% @ 1535 nm | AR/AR | 7343 | $420 |

| Custom Sizes | Custom Transmission | Custom | Custom | Request Quote |