Neodymium Doped Yttrium Aluminum Garnet (Nd:YAG) is one of the earliest and most widely used laser host crystals. It combines outstanding optical, thermal, and mechanical properties, making it a ubiquitous choice for near-infrared solid-state laser systems. Its cubic crystal structure ensures isotropic optical behavior, eliminating the need for polarization correction in most applications.

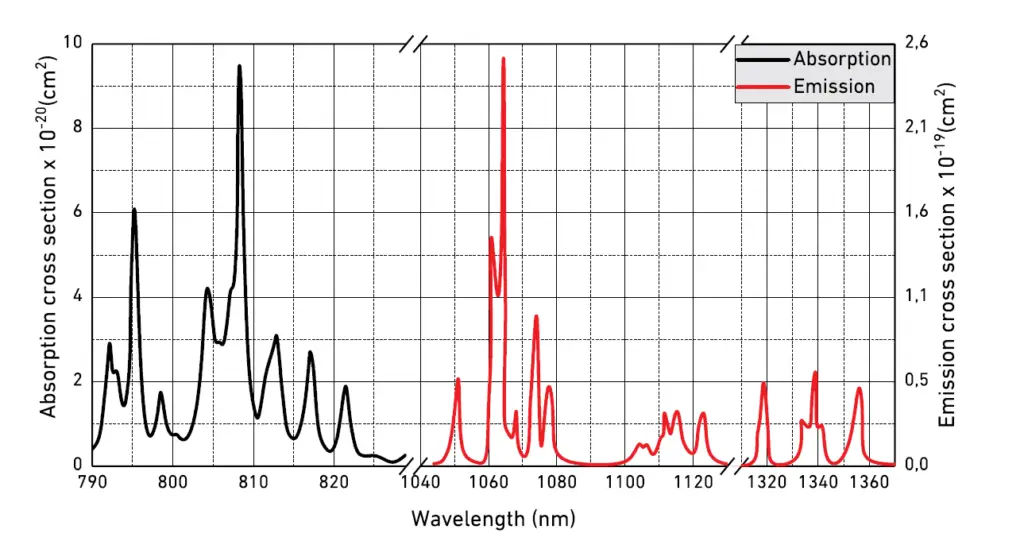

Nd:YAG exhibits high thermal conductivity, excellent optical homogeneity, and low laser-induced damage thresholds, making it ideal for both high-power and low-power laser operations. With an emission wavelength of 1064 nm and a strong absorption band at 808 nm, Nd:YAG efficiently converts pump energy into laser output with minimal losses.

Due to its reliability, Nd:YAG is used in diverse fields such as industrial machining, medical treatments, scientific research, and military applications. The crystal is available in a variety of dopant concentrations, dimensions, and coatings to meet specific operational requirements.

Nd:YAG crystals are essential in numerous industries due to their versatility and high performance. Below are some key applications:

| Property | Value |

|---|---|

|

Chemical Formula |

Nd:Y3Al5O12 |

|

Crystal Structure |

Cubic |

|

Lattice Constant |

12.01 Å |

|

Density |

4.56 g/cm³ |

|

Melting Point |

1970 °C |

|

Mohs Hardness |

8.5 (High mechanical strength) |

|

Thermal Conductivity |

14 W/m·K at 20 °C; 10.5 W/m·K at 100 °C |

|

Thermal Expansion Coefficient |

7.8 × 10⁻⁶ /K ( <111> ) |

|

Refractive Index |

1.82 at 1064 nm |

|

Stimulated Emission Cross-Section |

2.8 × 10⁻¹⁹ cm² at 1064 nm |

|

Property |

Value |

|---|---|

|

Lasing Wavelength |

1064 nm |

|

Pump Wavelength |

807.5 nm |

|

Relaxation Time of Terminal Lasing Level |

30 ns |

|

Fluorescent Lifetime |

550 µs |

|

Loss Coefficient |

0.003 cm⁻¹ at 1064 nm |

|

Linewidth |

0.6 nm |

|

Polarized Emission |

Unpolarized |

|

Thermal Birefringence |

High |

|

Specification |

Value |

|---|---|

|

Dimension Tolerance |

±0.1 mm (standard); ±0.01 mm (high precision) |

|

Clear Aperture |

Central 90% of the diameter |

|

Surface Quality |

10-5 Scratch-Dig |

|

Surface Flatness |

λ/8 at 633 nm |

|

Parallelism |

<20 arc seconds |

|

Perpendicularity |

<5 arc minutes |

|

Chamfer |

0.2 mm at 45° |

|

Damage Threshold |

>500 MW/cm² at 1064 nm (10 ns, 10 Hz) |

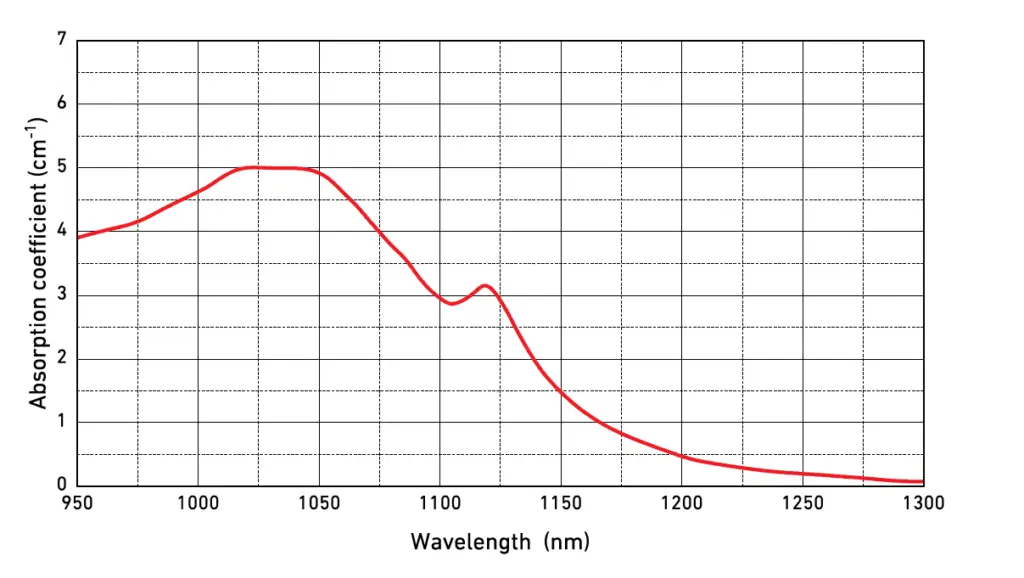

Nd:YAG crystals have a high transmission efficiency at 1064 nm and a strong absorption peak at 807.5 nm, ideal for diode pumping. Spectrum transmission curves show excellent transparency across visible and near-infrared wavelengths, ensuring minimal loss during operation.

(Graphical data available upon request.)

| Coating Type | Specifications |

|---|---|

| HR Coating | R > 99.8% at 1064 nm, R < 0.5% at 808 nm |

| AR Coating | R < 0.2% at 1064 nm, R < 0.5% at 808 nm |

| Custom Coatings | Available upon request |

Adhesion Test: Compliant with MIL-C-675C military standards, an adhesion test involved applying a tape that meets LT-90 specifications onto the lens film layer. The tape was affixed fully and then removed vertically. This procedure was performed three times, resulting in no blistering or peeling.

Temperature Test: In line with MIL-C-675C specifications, test pieces were subjected to temperatures of -62±1℃ and 71±1℃. After maintaining them at room temperature (16℃~32℃) for two hours, the adhesion test was repeated, confirming no film detachment.

Abrasion Resistance Test: Conforming to MIL-C-675C and CCC-C-440 standards, the abrasion resistance test involved a gauze tester applying a minimum force of 1.0 lbs (0.45 kg) to the film. This was repeated 25 times with gauze widths of 1/4 inch (6.4mm) and 3/8 inch (9.5mm), ensuring no damage occurred to the film surface.

Humidity Test: Under MIL-C-675C criteria, the test piece was placed in a controlled temperature and humidity chamber set to 49 ±2℃ and 95%~100% humidity for 24 hours. The film remained intact, with no peeling, scratches, or other defects.

Solvent and Cleaning Testing: Following MIL-C-675C specifications, test pieces were exposed to room temperature conditions (16℃~32℃) and tested with acetone and alcohol for at least 10 minutes each. After air drying and subsequent cleaning with a cotton cloth soaked in alcohol, the film surface showed no signs of peeling or scratches.

Salt Spray Test: After 100 hours in a 35°C environment with a 5% saltwater concentration, the film showed no signs of damage.

| Product Code | Dimensions (mm) | Doping Level (Nd) | Coating | Price (USD) |

|---|---|---|---|---|

| NDYAG-01 | 3 × 3 × 0.5 | 1.0% | AR @ 808 nm / 1064 nm | Request Quote |

| NDYAG-02 | 6 × 6 × 1 | 0.6% | Customizable | Request Quote |

| NDYAG-03 | 10 × 10 × 2 | 1.1% | Customizable | Request Quote |

| Custom-NDYAG | Customizable | Customizable | Customizable | Request Quote |