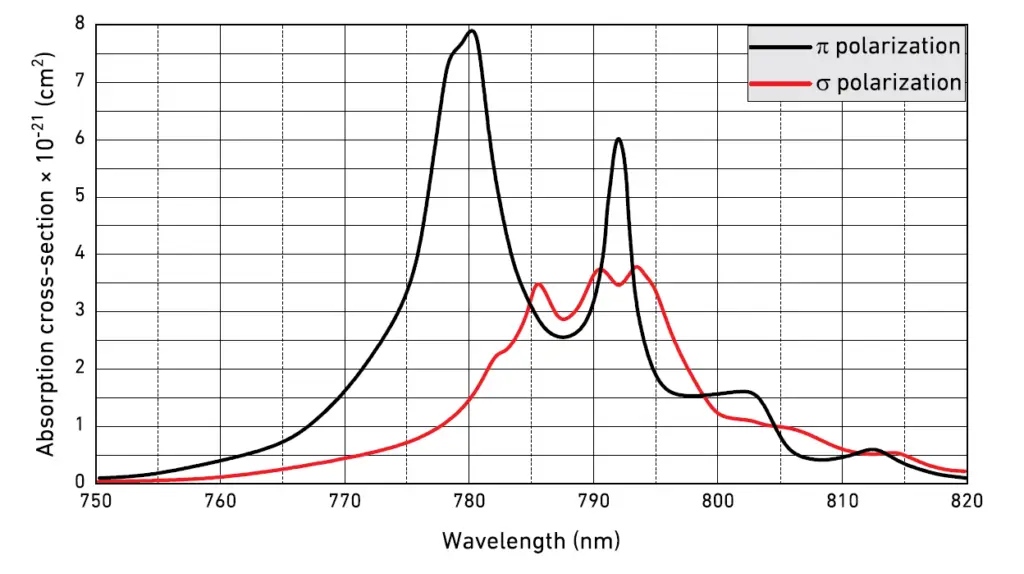

Tm:YLF (Thulium-doped Lithium Yttrium Fluoride) crystal is an advanced laser medium featuring high absorption peaks around 792 nm, making it ideal for laser diode pumping. Its unique cross-relaxation process doubles the number of ions in the upper laser level, enhancing the efficiency of each pump photon. Tm:YLF crystals are widely used as a pump source for Ho:YAG lasers due to the good overlap of their emission and absorption spectra. Additionally, the thermal refractive index of Tm:YLF decreases with temperature, leading to a negative thermal lens effect, which, when combined with end-face bulging compensation, ensures excellent beam stability and performance. This crystal’s superior polarization purity and stable operation make it ideal for high-precision applications.

Tm:YLF crystals are used in a variety of applications, including:

By leveraging Tm:YLF Crystal unique properties, these applications achieve high power output, precise targeting, and low thermal distortion, making this crystal indispensable in cutting-edge laser systems.

| Property | Specification |

|---|---|

| Orientation | c-cut |

| Clear Aperture | >90% |

| Face Dimensions Tolerance | ±0.1 mm |

| Length Tolerance | ±0.1 mm |

| Parallelism Error | <20 arcsec |

| Perpendicularity Error | <10 arcmin |

| Protective Chamfers | <0.1 mm at 45° |

| Surface Quality | 20-10 S-D |

| Surface Flatness | λ/10 @ 632.8 nm |

| Crystal Structure | Tetragonal |

| Density | 3.99 g/cm³ |

| Thermal Conductivity | 6 W/m·K |

| Mohs Hardness | 5 |

| dn/dT | -4.6 x 10^-6 (°C)^-1 |

| Typical Doping Level | 2-4 at.% |

| Optical Property | Specification |

|---|---|

| Absorption Peak Wavelength | 792 nm |

| Absorption Cross-Section at Peak | 0.55 x 10^-19 cm² |

| Absorption Bandwidth at Peak | ~5 nm |

| Laser Wavelength | 1900 nm |

| Lifetime of Tm³⁺ Energy Level | 16 ms |

| Emission Cross-Section @ 1900 nm | 0.4 x 10^-19 cm² |

| Refractive Index @ 1064 nm | nₒ = 1.448, nₑ = 1.446 |

| Specification | Value |

|---|---|

| Orientation | c-cut |

| Face Dimensions Tolerance | ±0.1 mm |

| Surface Quality | 20-10 S-D |

| Surface Flatness | λ/10 @ 632.8 nm |

| Parallelism Error | <20 arcsec |

| Protective Chamfers | <0.1 mm at 45° |

| Laser-Induced Damage Threshold (LIDT) | >10 J/cm² @ 1900 nm, 10 ns |

Absorption and emission spectra have been optimized for diode pumping at 792 nm and laser output at 1900 nm. This data is critical for system design and alignment.

| Face Dimensions | Length | End Faces | Doping | Coatings | Price (USD) |

|---|---|---|---|---|---|

| 3 x 3 mm | 8 mm | Brewster-angle cut | 3% | Uncoated | 540 |

| 3 x 3 mm | 8 mm | Right-angle cut | 3% | AR@792 nm + 1800-1960 nm | 590 |

| Custom Size | Custom | Upon Request | Custom | Upon Request | Custom Pricing |