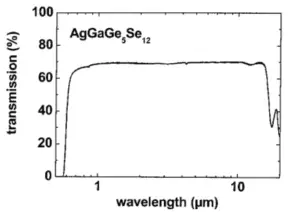

The AgGaGe5Se12 Crystal is a cutting-edge nonlinear optical material featuring a broad transmission range of 0.6 – 16.5 µm, making it ideal for mid-infrared (mid-IR) laser applications. With a high bandgap of 2.2 eV, this crystal demonstrates superior performance in frequency conversion processes such as SHG, SFG, and OPA. The laser damage threshold of 220 MW/cm² (1.06 µm, 15 ns, 1 Hz) ensures its durability under high-power operations. AgGaGe5Se12 offers enhanced properties over its predecessors, AgGaS2 and AgGaSe2, providing greater application flexibility for advanced laser systems

| Property | Value |

|---|---|

| Chemical Formula | AgGaGe5Se12 |

| Crystal Structure | Orthorhombic |

| Lattice Parameters | a = 1.065 nm, b = 0.785 nm |

| Density | 5.4 g/cm³ |

| Bandgap Width | 2.2 eV |

| Mohs Hardness | 2.8 |

| Thermal Conductivity | 0.45 W/(m·K) |

| Melting Point | 825 °C |

| Property | Value |

|---|---|

| Transparency Range | 0.6 – 16.5 µm |

| Nonlinear Coefficients | d31 = 15 pm/V |

| Refractive Indices | n0 = 2.48, ne = 2.66 |

| Laser Damage Threshold | 220 MW/cm² (1.06 µm, 15 ns) |

| Specification | Value |

|---|---|

| Orientation Tolerance | ±0.5° |

| Clear Aperture | >90% |

| Surface Flatness | λ/6 @ 633 nm |

| Surface Quality (Scratch/Dig) | 40-20 |

| Parallelism | <30 arc seconds |

| Perpendicularity | <10 arc minutes |

| Clear Aperture Deviation | ±0.1 mm |

| Length Tolerance | ±0.1 mm (1 – 10 mm length) |

| ±0.5 mm (>10 mm length) |

(Spectrum transmission curves for AgGaGe5Se12 Crystal can be provided upon request, showcasing its high transmission efficiency across the 0.6 – 16.5 µm range.)

| Product Code | Dimensions (mm) | Coating Type | Application | Price (USD) |

|---|---|---|---|---|

| AGGS-1010-AR | 10 × 10 × 2 | AR Coating | Mid-IR Laser Systems | Request |

| AGGS-2020-AR | 20 × 20 × 5 | AR Coating | High-Power Applications | Request |

| Custom | Custom Sizes | Customized | Tailored for Specific Needs | Request |