Germanium windows offer superior transmission capabilities in the 2-14 µm waveband, making them suitable for both mid-wave and long-wave infrared (IR) systems. As a prevalent choice in the production of IR windows and lenses, germanium is integral to thermal imaging technologies.

These high-density windows exhibit a thermal escape characteristic, where increased window temperatures lead to reduced transmission efficiency. Germanium windows are widely utilized across various sectors, including defense and aerospace industries, life and medical sciences, and industrial OEMs, among other applications requiring infrared functionality.

N-type germanium is a type of semiconductor that has been doped with elements to add extra electrons, making electrons the majority charge carriers. Below is a detailed overview of N-type germanium, including its properties, uses, and key characteristics.

Doping Elements:

Electrical Properties:

Uses in Technology:

Advantages:

Comparison to Silicon:

Summary:

N-type germanium is a crucial material in the field of electronics and optics. With its unique combination of metalloid properties, high electron mobility, and effectiveness in semiconductor applications, it continues to be a valuable material in advanced technology manufacturing. Its use in transistors, integrated circuits, and optical coatings highlights its versatility and importance in modern electronics and optical devices.

| Specification | Value |

|---|---|

| Bevel | Protective as needed |

| Coefficient of Thermal Expansion (CTE) (10⁻⁶/°C) | 6.1 |

| Edges | Fine Ground |

| Knoop Hardness (kg/mm²) | 780 |

| Poisson’s Ratio | 0.28 |

| Surface Flatness (P-V) | λ/10 @ 10.6µm |

| Wavelength Range (nm) | 2000 – 14000 |

| Clear Aperture (%) | As Requested |

| Density (g/cm³) | 5.33 |

| Index of Refraction (nᵈ) | 4.002 @ 11µm |

| Parallelism (arcmin) | <3 |

| Substrate | Germanium (Ge) |

| Surface Quality | 40-20 |

| Young’s Modulus (GPa) | 102.7 |

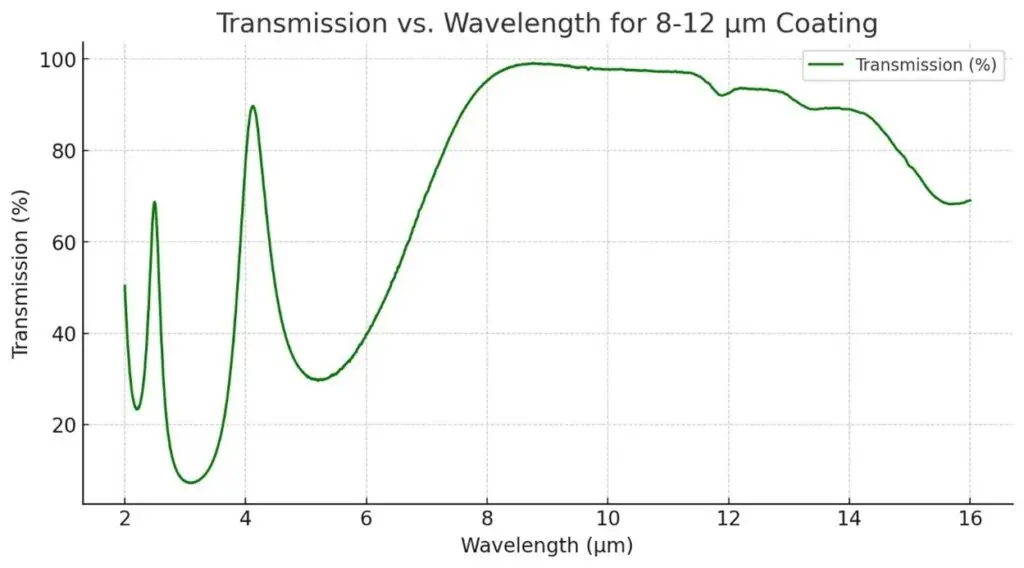

POC offers Germanium (Ge) Windows with three options for anti-reflection coatings to cater to different infrared (IR) applications: a 3 – 5μm coating for mid-infrared use, a 3 – 12μm coating for broadband multispectral applications, and an 8 – 12μm coating for thermal imaging systems. Given germanium’s high index of refraction, approximately 4.0 across the 2 – 14μm wavelength range, applying an anti-reflection coating is crucial for achieving adequate transmission within the desired spectral region.

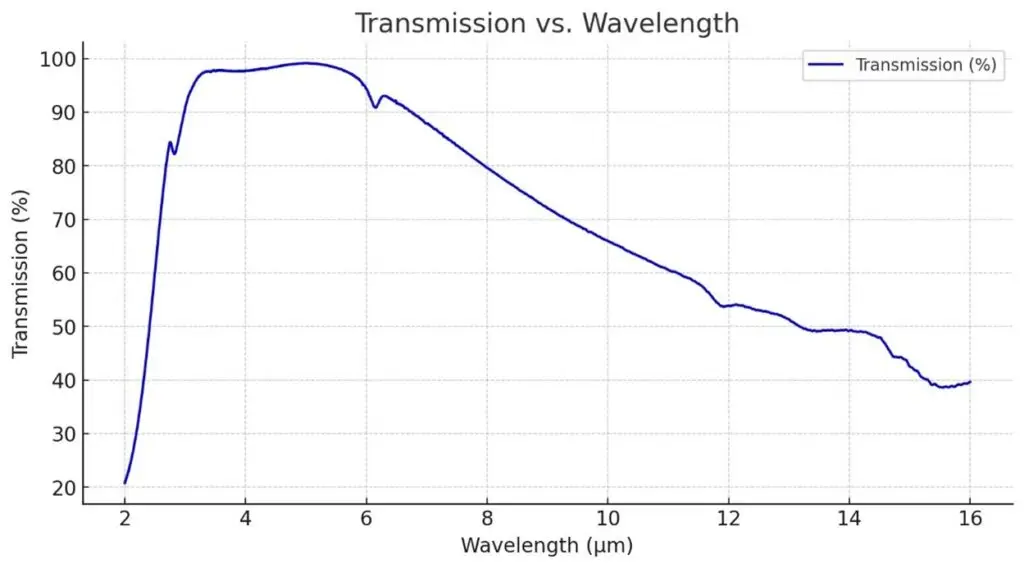

Typical transmission of a 3mm thick Ge window with BBAR (3000-5000nm) coating at 0° AOI. It indicates the coating design wavelength range, with the following specification: Ravg <3% @ 3000 – 5000nm

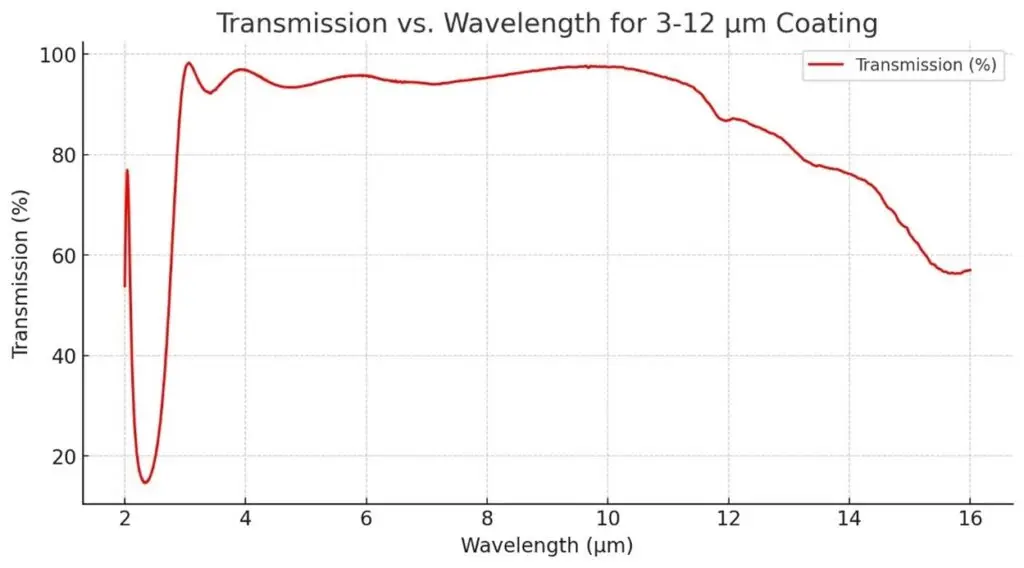

Typical transmission of a 3mm thick Ge window with BBAR (3000-12000nm) coating at 0° AOI. It indicates the coating design wavelength range, with the following specification: Ravg <5.0% @ 3 – 12μm

POC offers Germanium (Ge) Windows with three options for anti-reflection coatings to cater to different infrared (IR) applications: a 3 – 5μm coating for mid-infrared use, a 3 – 12μm coating for broadband multispectral applications, and an 8 – 12μm coating for thermal imaging systems. Given germanium’s high index of refraction, approximately 4.0 across the 2 – 14μm wavelength range, applying an anti-reflection coating is crucial for achieving adequate transmission within the desired spectral region.

POC Diamond-Like Carbon (DLC) Coated Germanium Windows are crafted for robustness and longevity. These windows are equipped with a high-efficiency broadband anti-reflection coating on one side and a durable DLC coating on the opposite side, ensuring outstanding transmission and resistance to environmental conditions. The DLC-coated surface is engineered to endure extreme temperature fluctuations ranging from -80 to +160°F, continuous exposure to salt spray for 24 hours, salt solubility during a 24-hour immersion, and up to 5,000 wiper oscillations with a sand and slurry mixture. Moreover, POC DLC Coated Germanium Windows comply with the MIL-C-675C standards for severe abrasion resistance.

Germanium is prone to thermal runaway, a condition where its transmission efficiency declines as temperatures rise. Therefore, it is recommended to operate POC Germanium Windows at temperatures below 100°C to maintain optimal performance. Additionally, with a high density of 5.33 g/cm³, germanium windows should be carefully integrated into designs where weight sensitivity is a factor.

The material’s Knoop Hardness, at 780, is roughly double that of magnesium fluoride, making germanium windows exceptionally suitable for demanding IR applications where durable optics are essential.

POC offers Germanium (Ge) Windows with three options for anti-reflection coatings to cater to different infrared (IR) applications: a 3 – 5μm coating for mid-infrared use, a 3 – 12μm coating for broadband multispectral applications, and an 8 – 12μm coating for thermal imaging systems. Given germanium’s high index of refraction, approximately 4.0 across the 2 – 14μm wavelength range, applying an anti-reflection coating is crucial for achieving adequate transmission within the desired spectral region.

At Photonics On Crystals (POC), we specialize in delivering world-class Germanium windows renowned for their superior transmission capabilities across the 2-14 µm waveband. These windows are integral to mid-wave and long-wave infrared (IR) systems, making them a popular choice for thermal imaging technologies. Whether in defense, aerospace, life sciences, medical applications, or industrial OEMs, Germanium windows offer exceptional performance and reliability, supporting cutting-edge advancements in infrared functionality.

POC’s Optical Infrared Germanium windows serve diverse sectors with unparalleled efficiency: